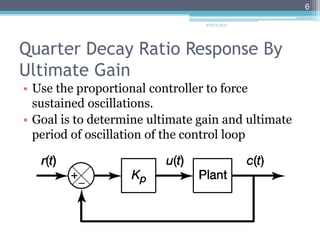

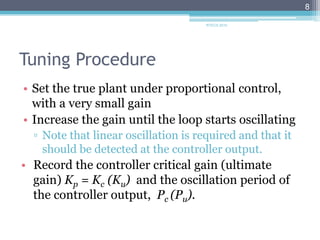

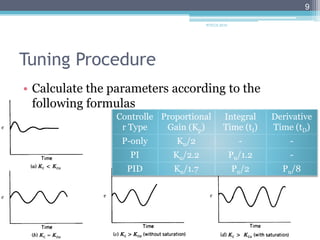

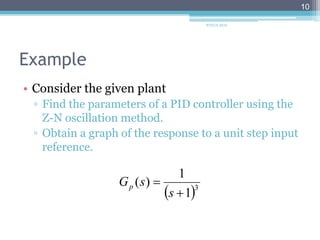

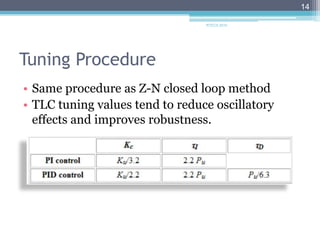

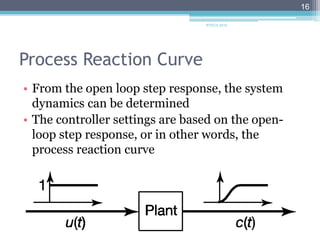

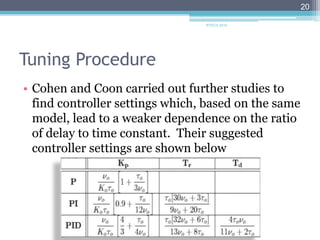

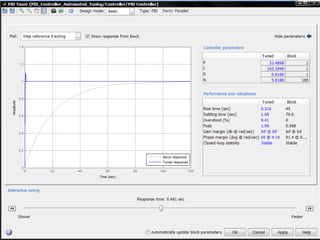

This document discusses various empirical techniques for tuning PID controllers, including the Ziegler-Nichols and Cohen-Coon reaction curve methods. The Ziegler-Nichols method determines controller parameters by forcing sustained oscillations and measuring the ultimate gain and period. The Cohen-Coon method analyzes the open-loop step response curve to estimate parameters. Simulation tools can also assist in empirically tuning controllers to achieve desired closed-loop responses.