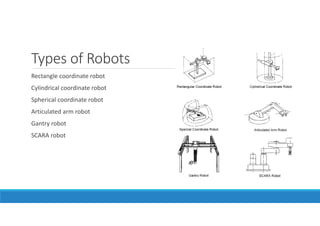

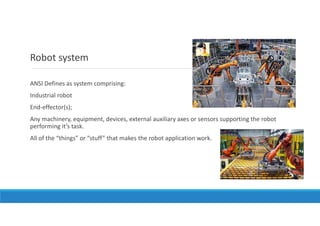

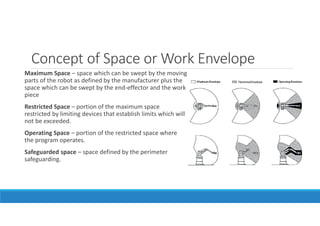

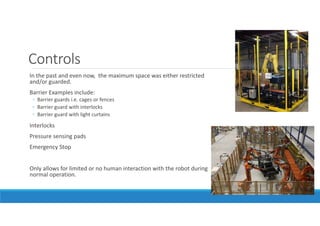

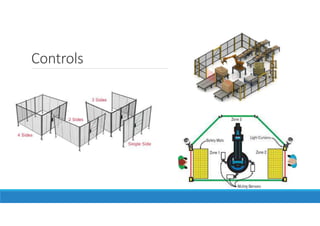

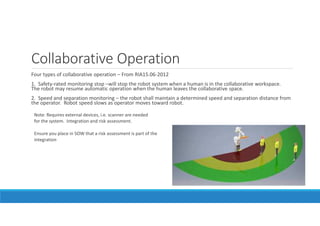

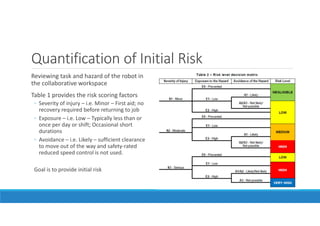

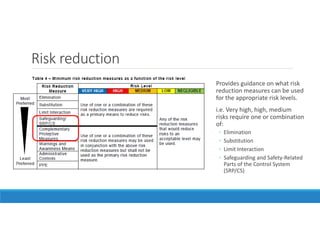

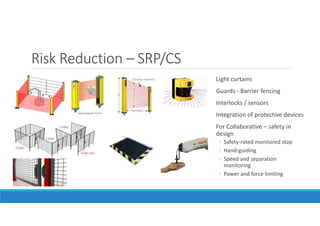

The document discusses the historical growth and safety concerns of industrial robotics, particularly emphasizing the rapid expansion in various industries from the 1980s onward. It outlines the definitions of robots and robotics systems according to ANSI standards, as well as the types of robots, and highlights the hazards associated with their operation and maintenance. The text also covers safety standards and risk assessment methodologies specific to both collaborative and non-collaborative robot systems, underscoring the need for proper safeguards and training.