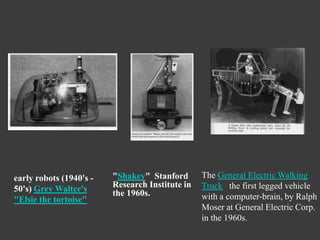

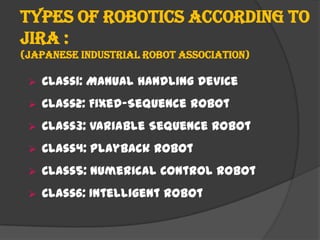

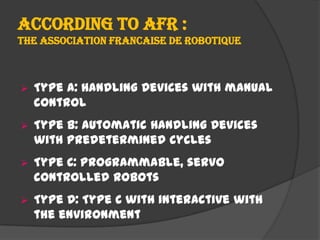

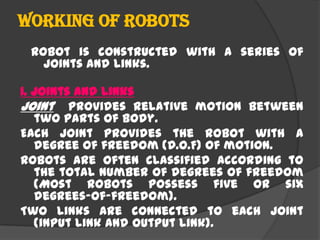

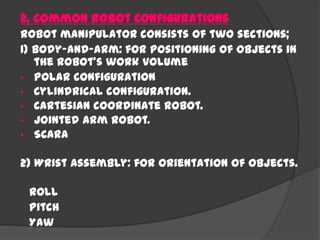

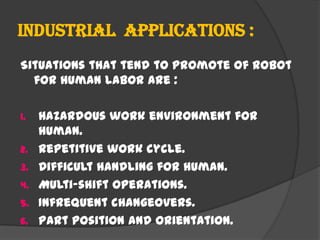

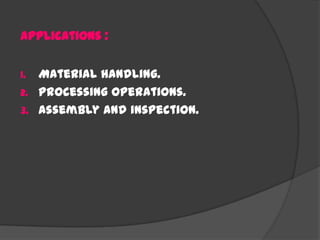

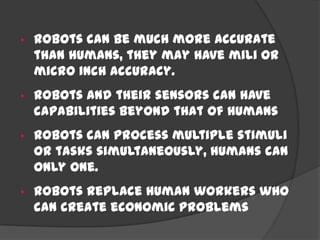

Industrial robots are general purpose machines that can perform tasks faster and continuously like humans but without needs for pay, food, or breaks. They have evolved from early prototypes in the 1940s-1960s to become multifunctional manipulators used for tasks that are dangerous, repetitive, or difficult for humans. Robots are classified and their movements controlled through various joint and drive systems along with sensors to coordinate their operations in industrial applications like materials handling, processing, and assembly.