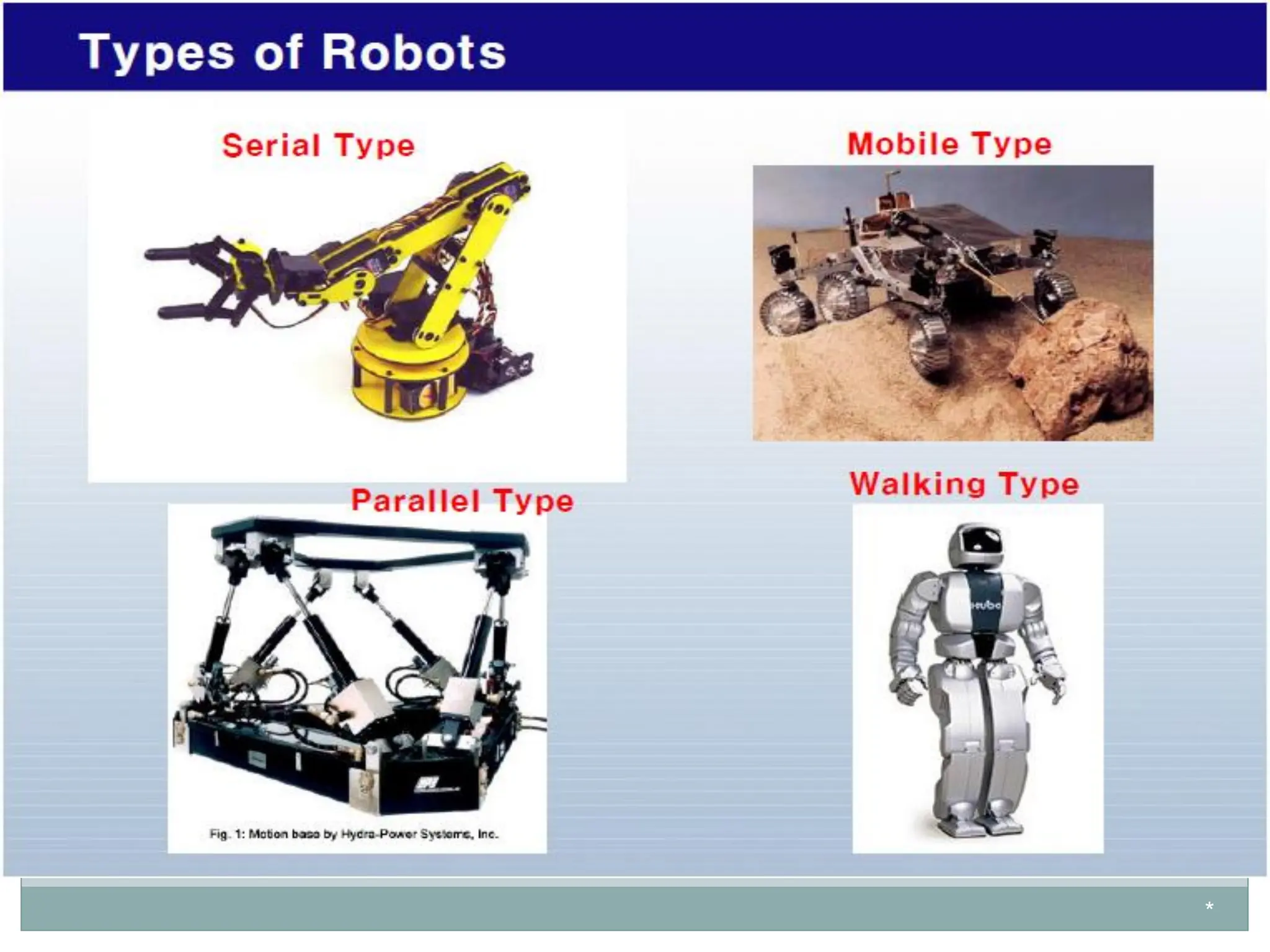

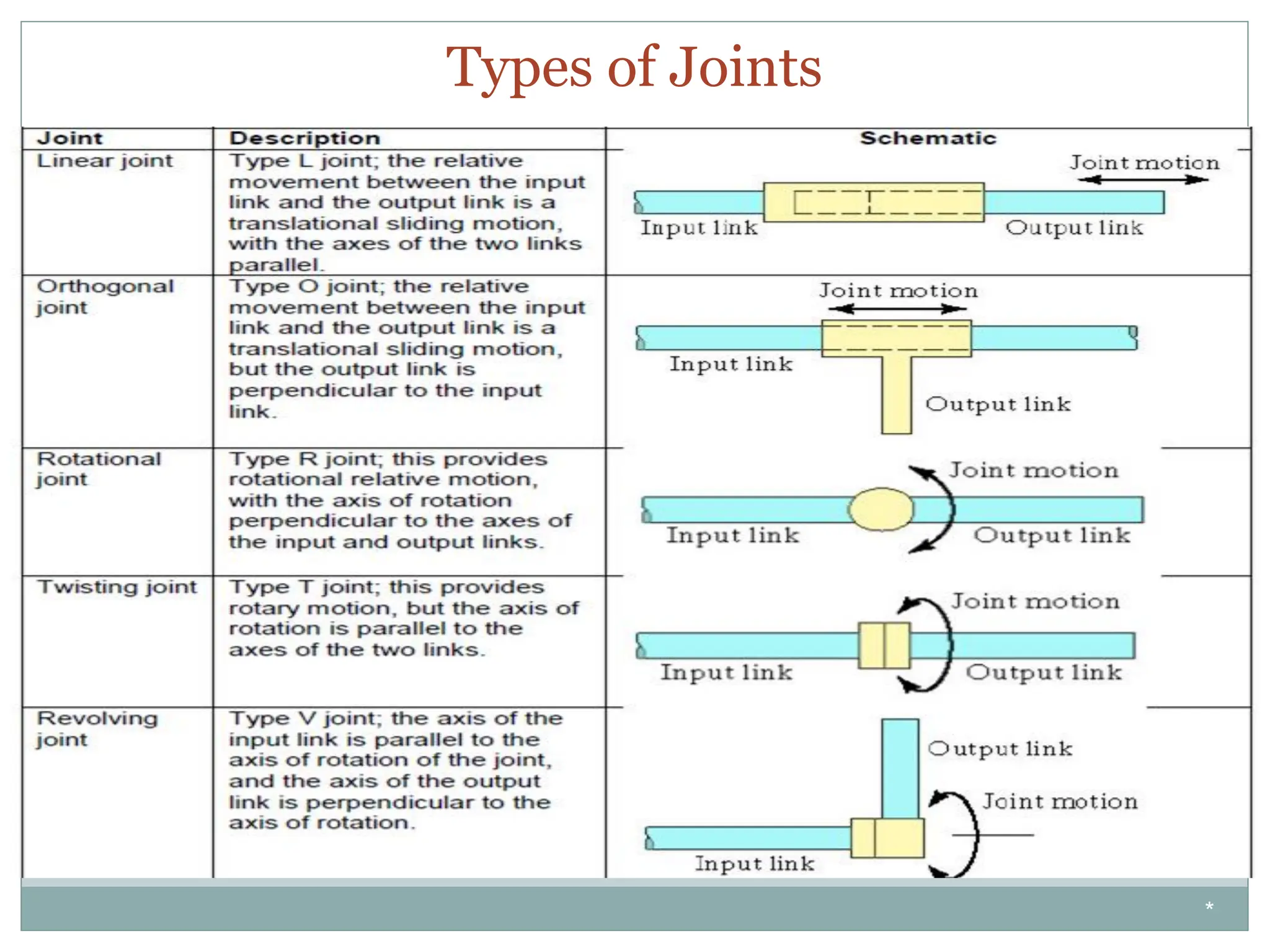

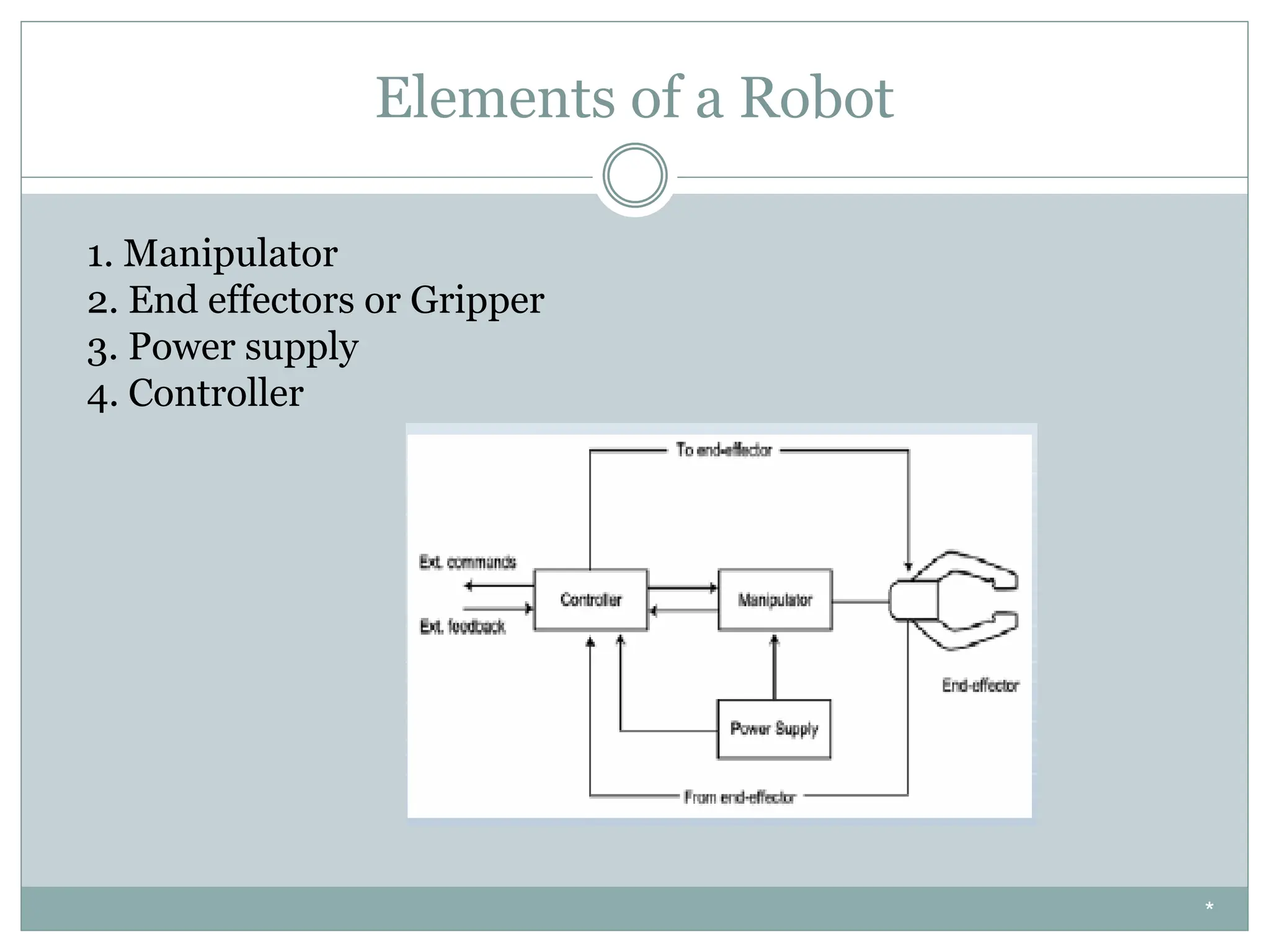

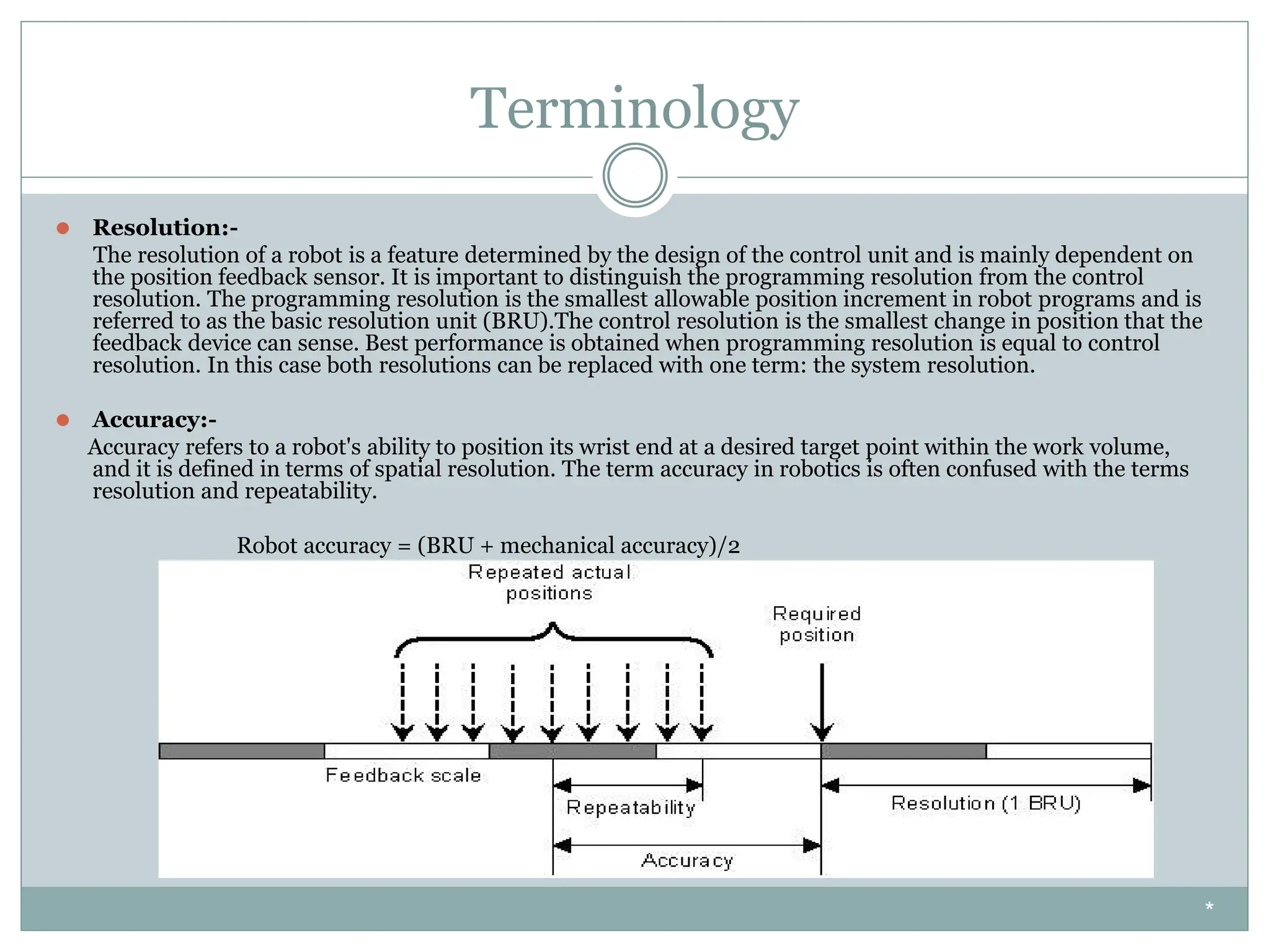

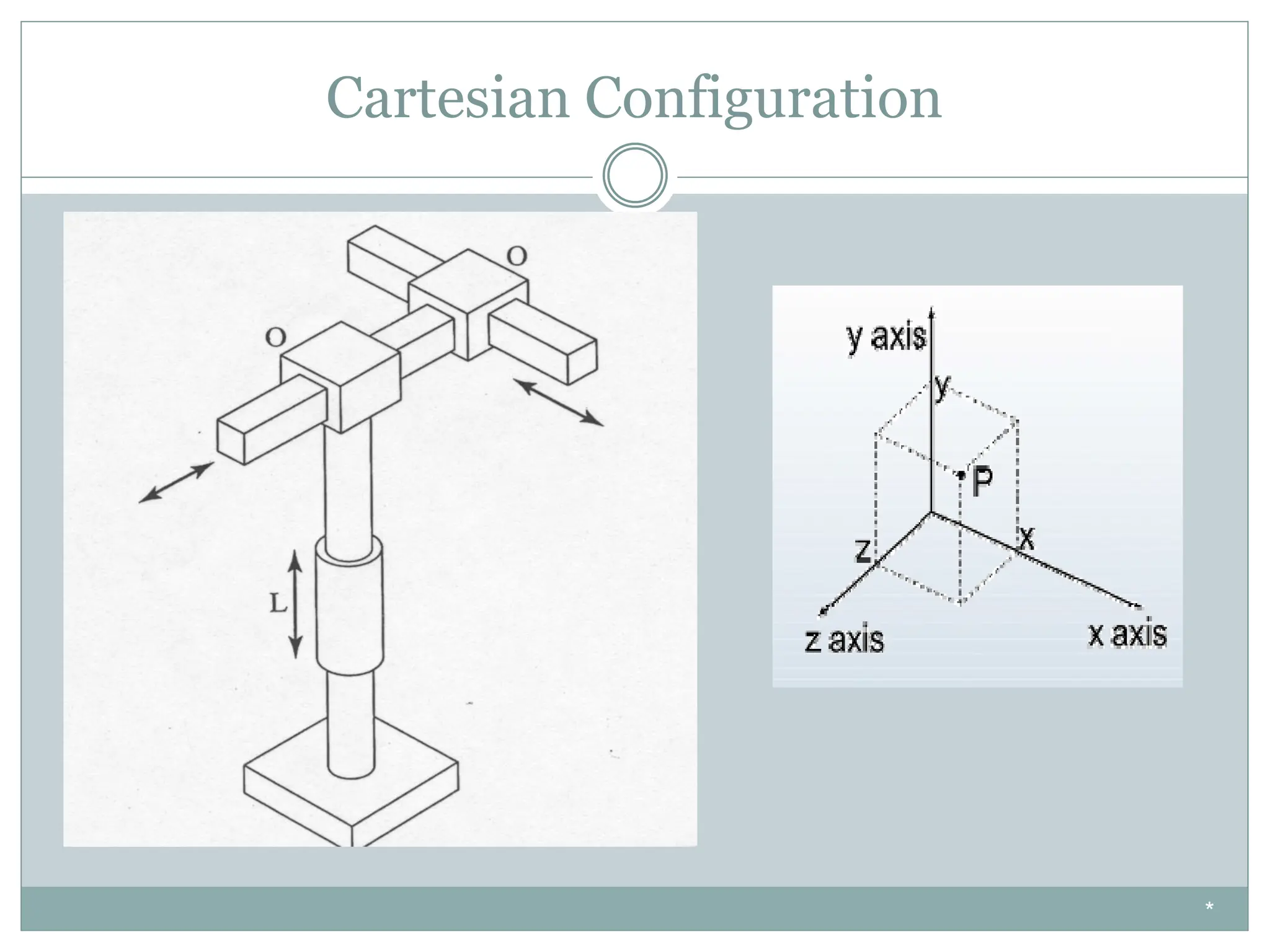

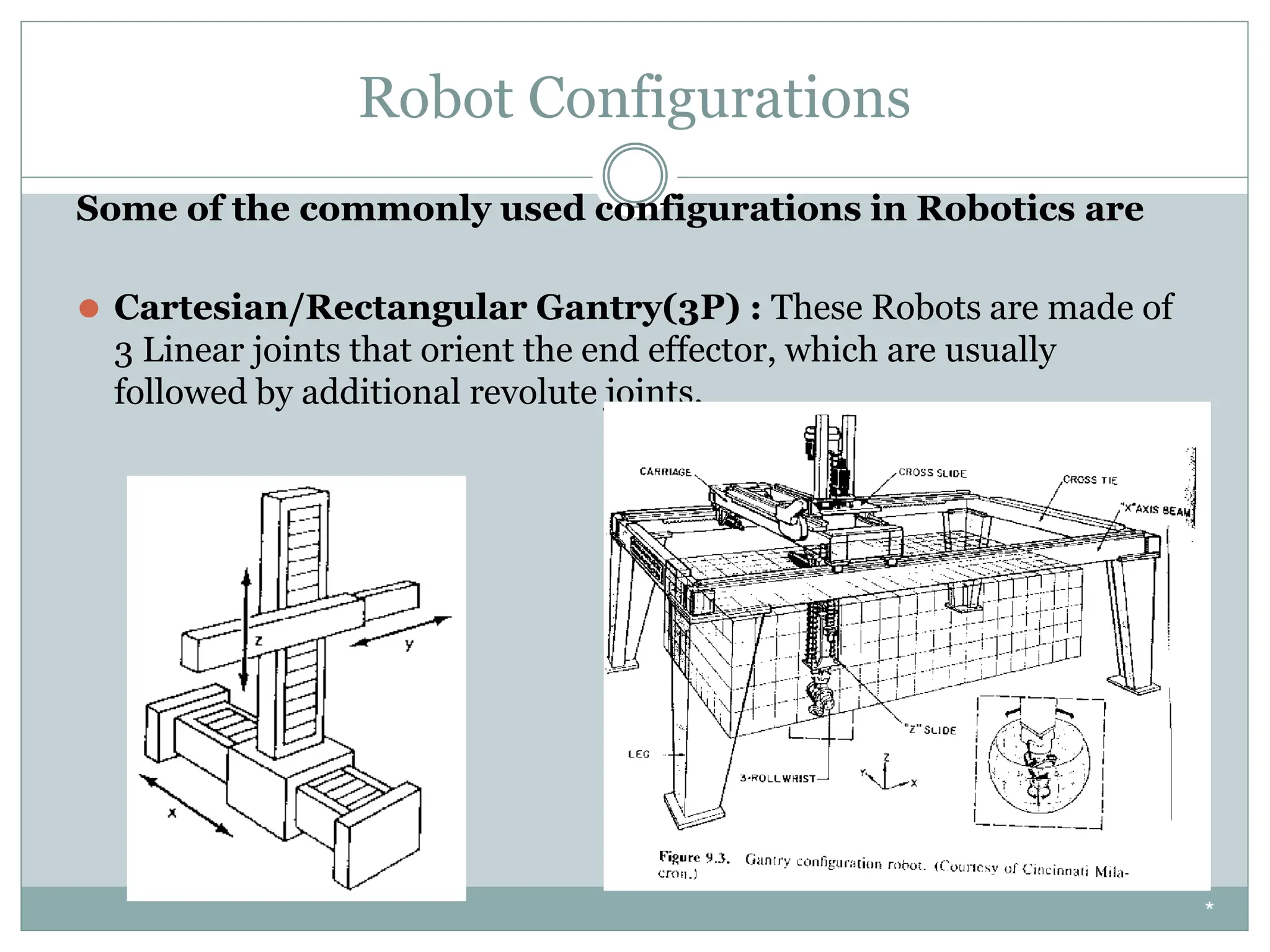

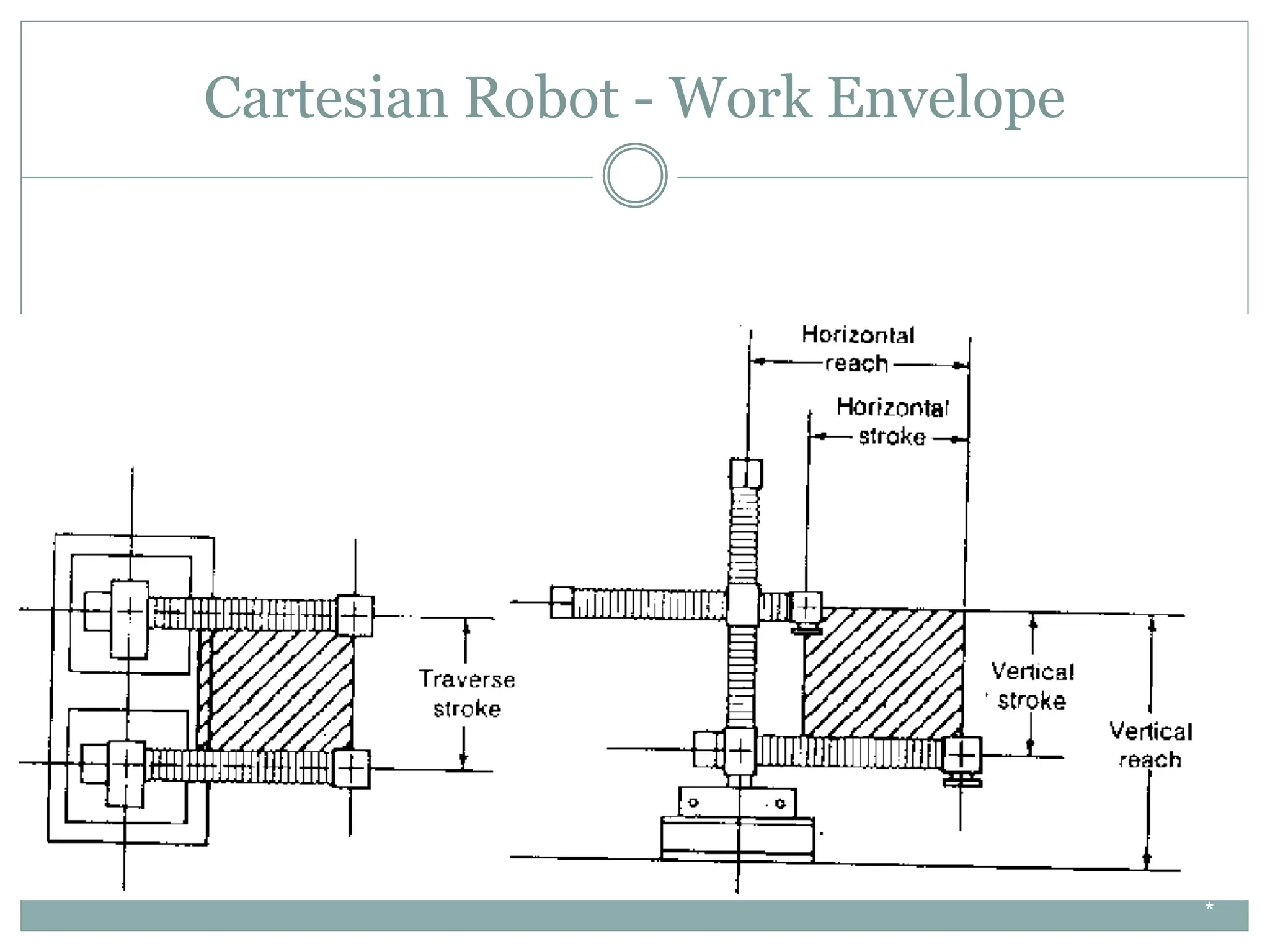

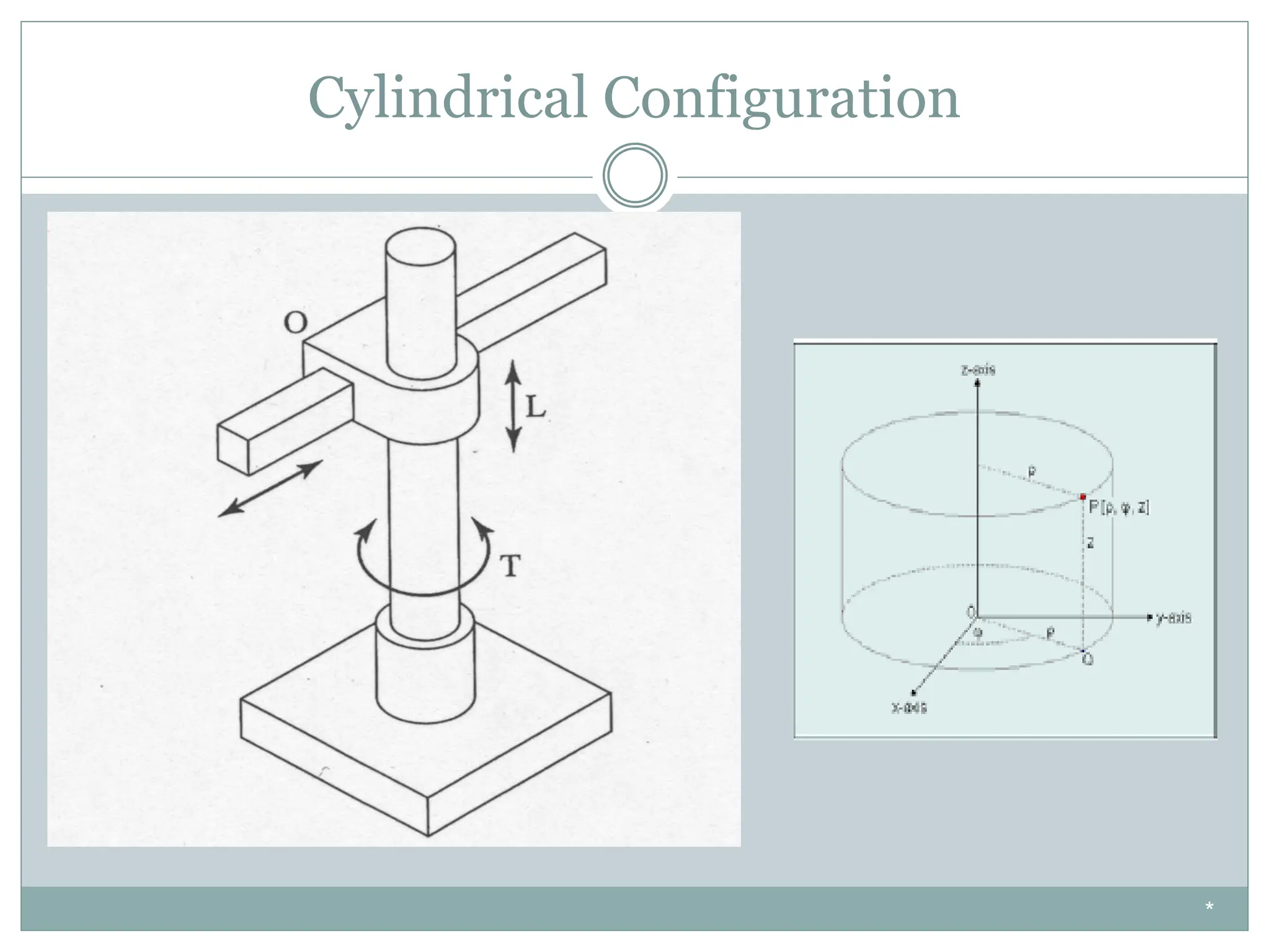

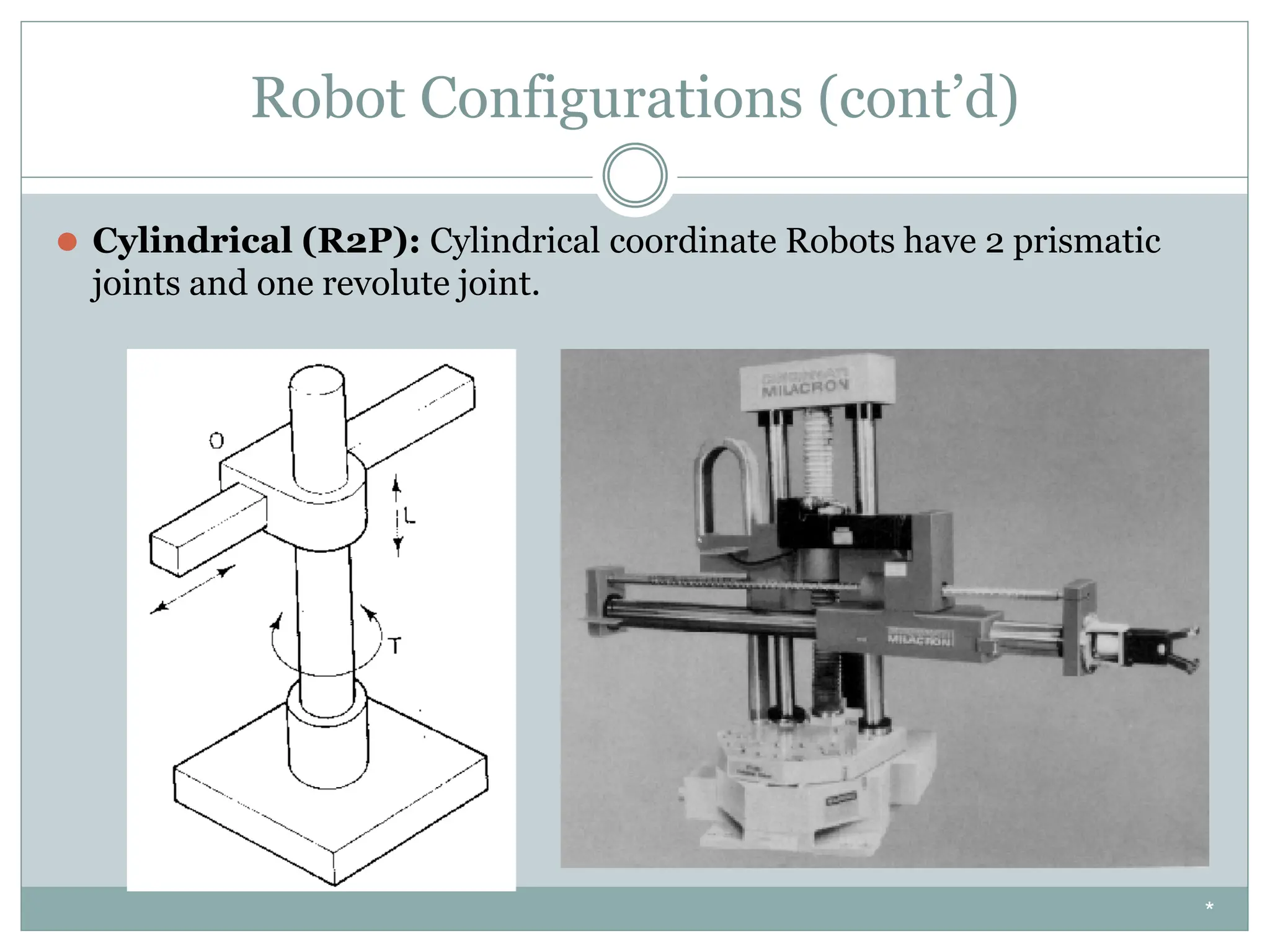

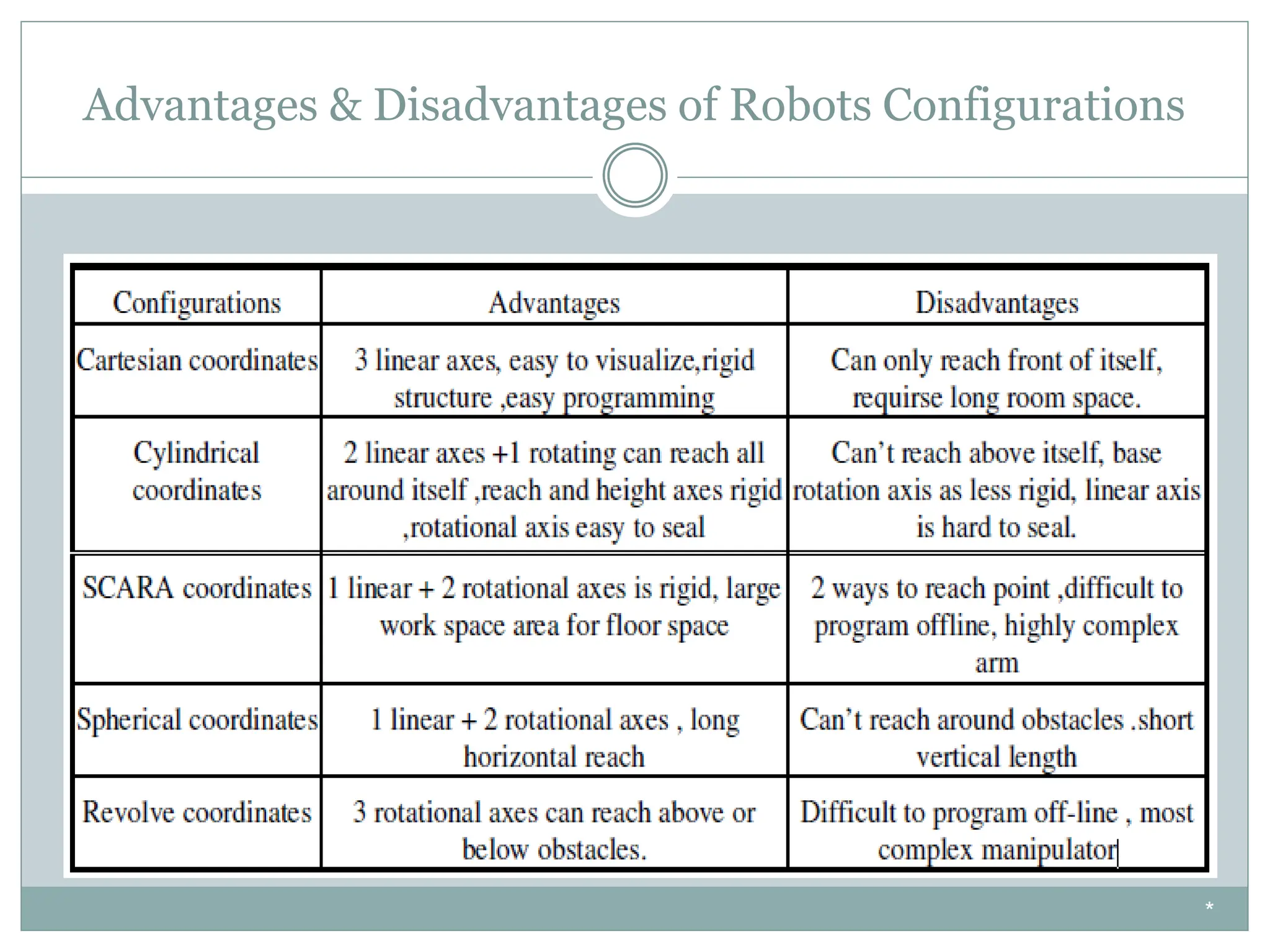

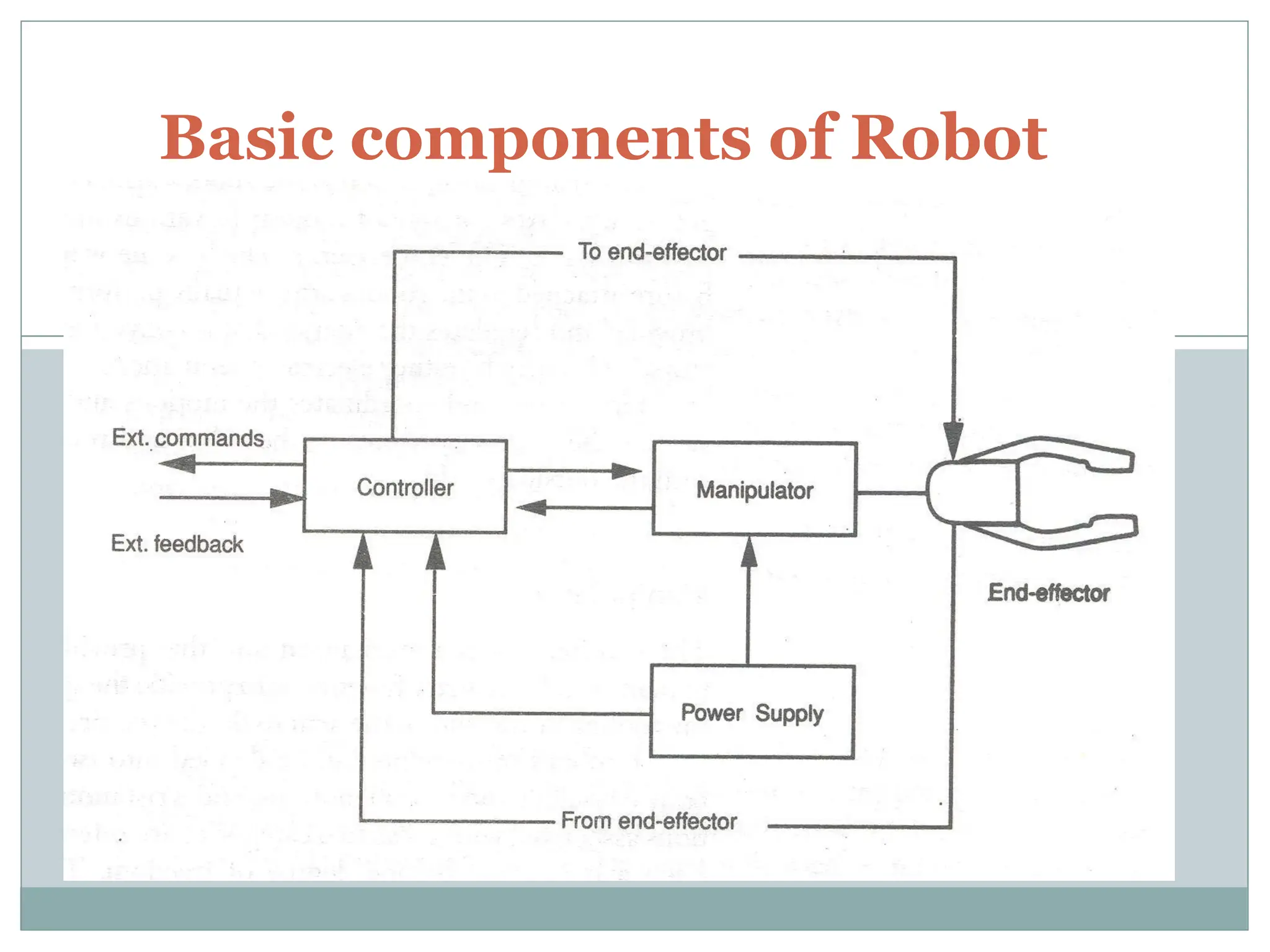

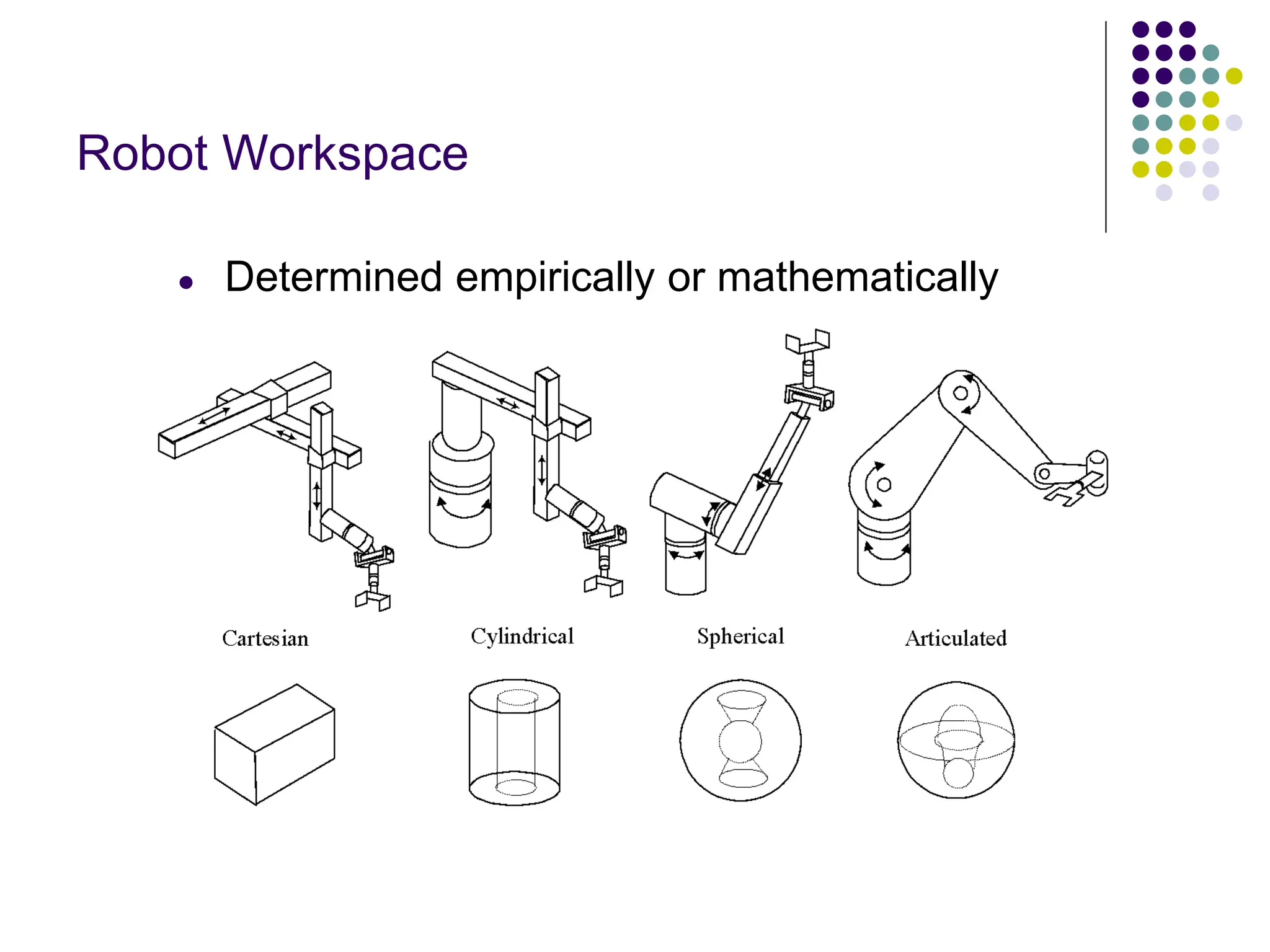

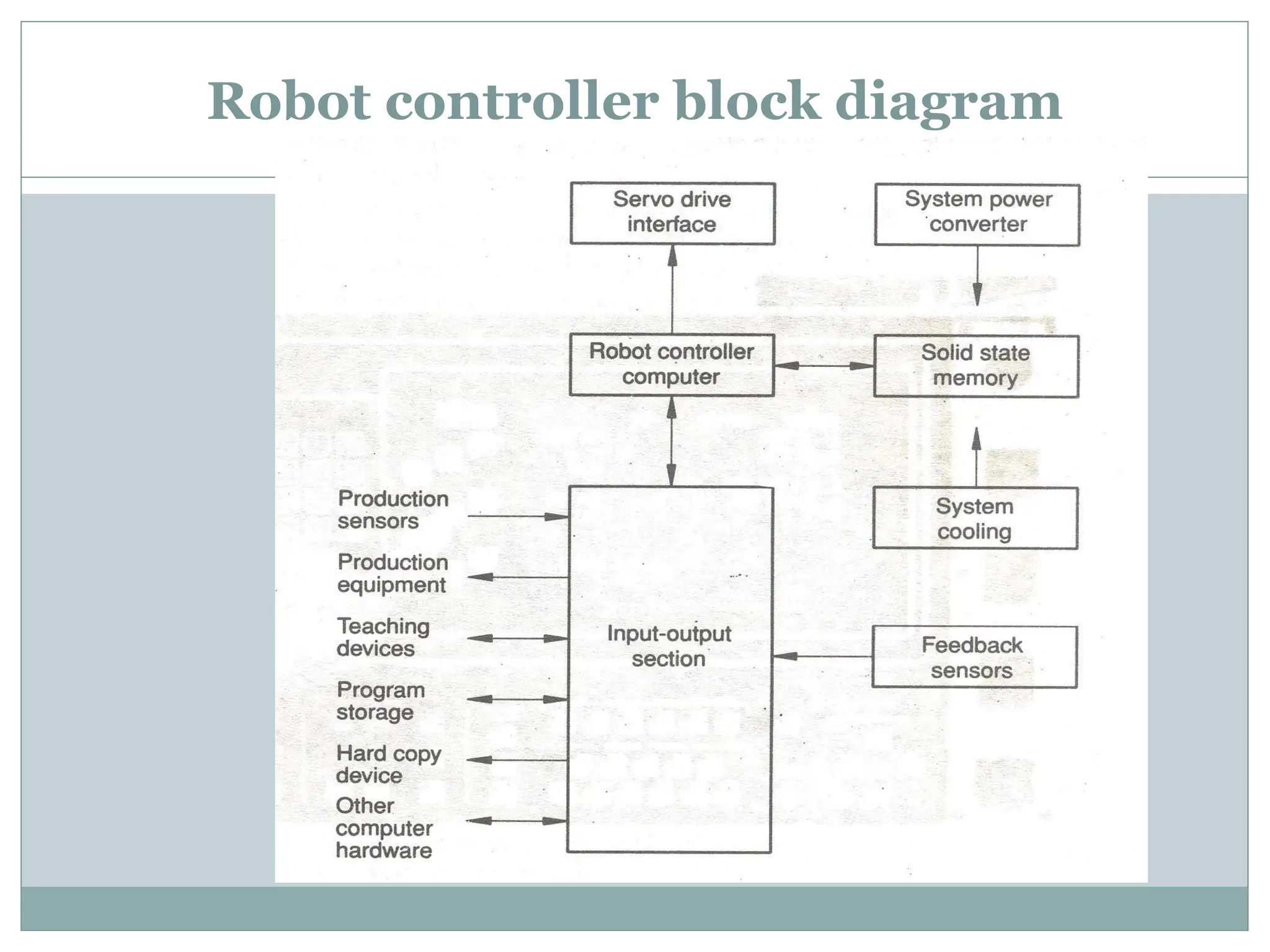

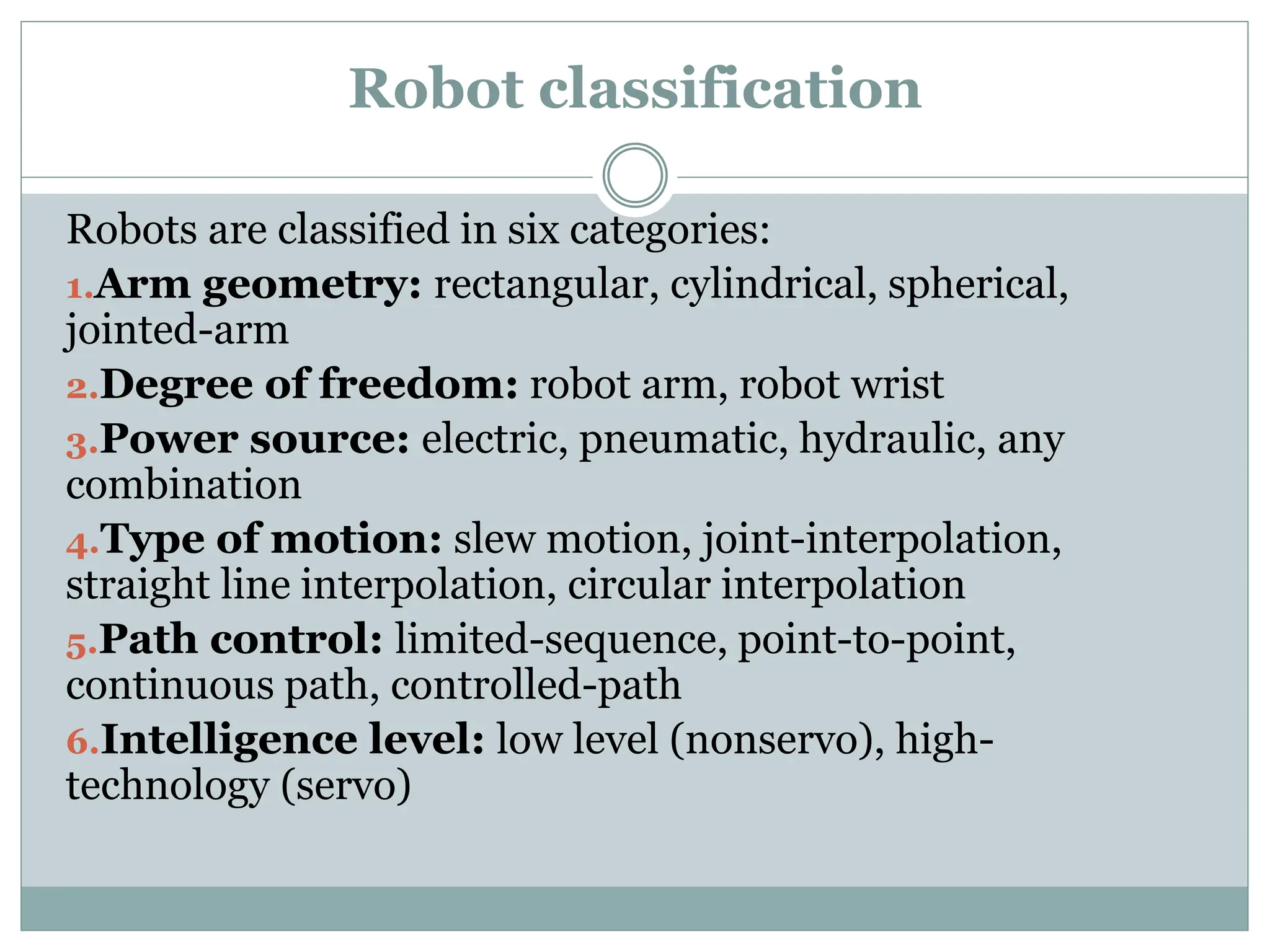

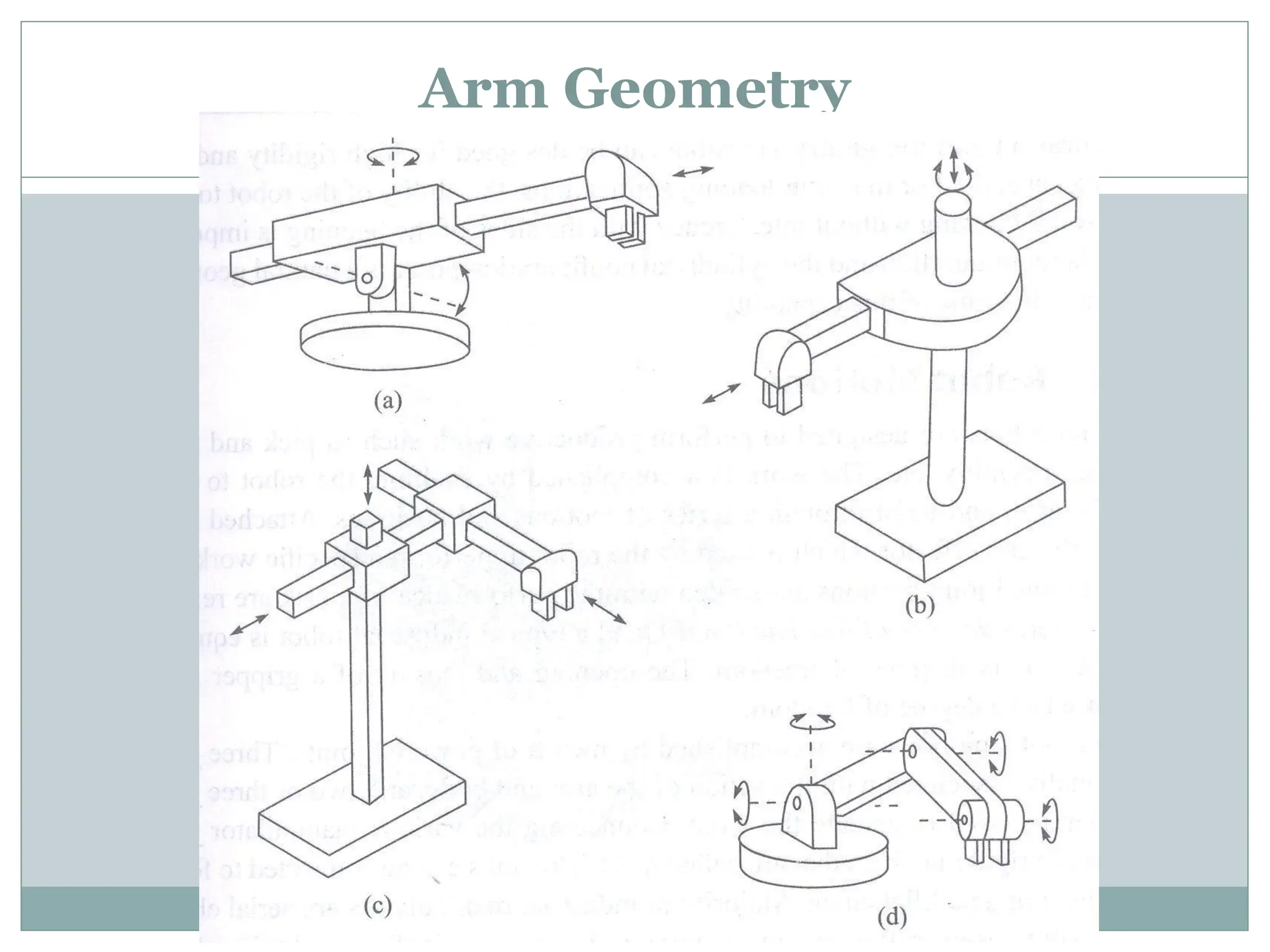

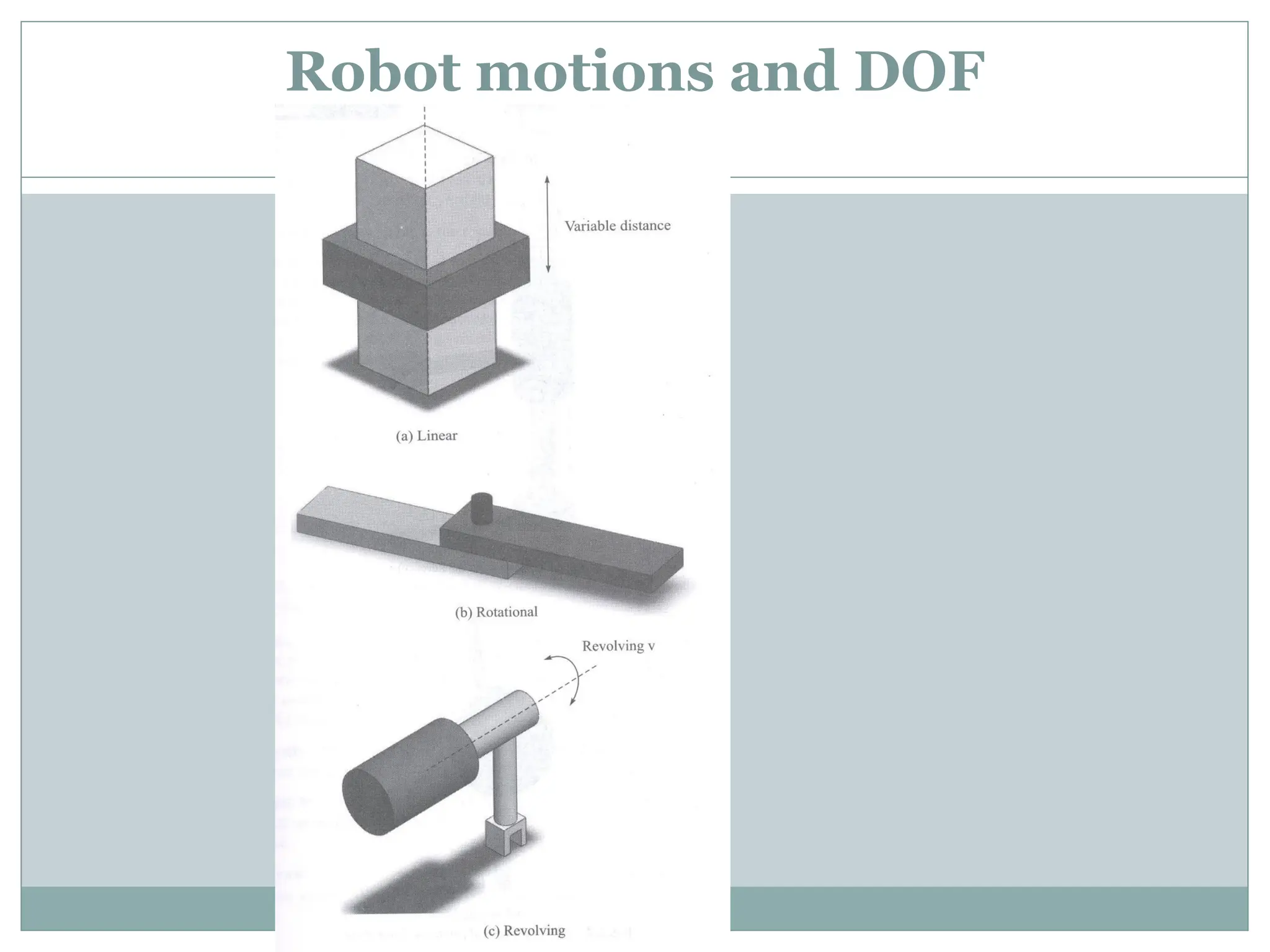

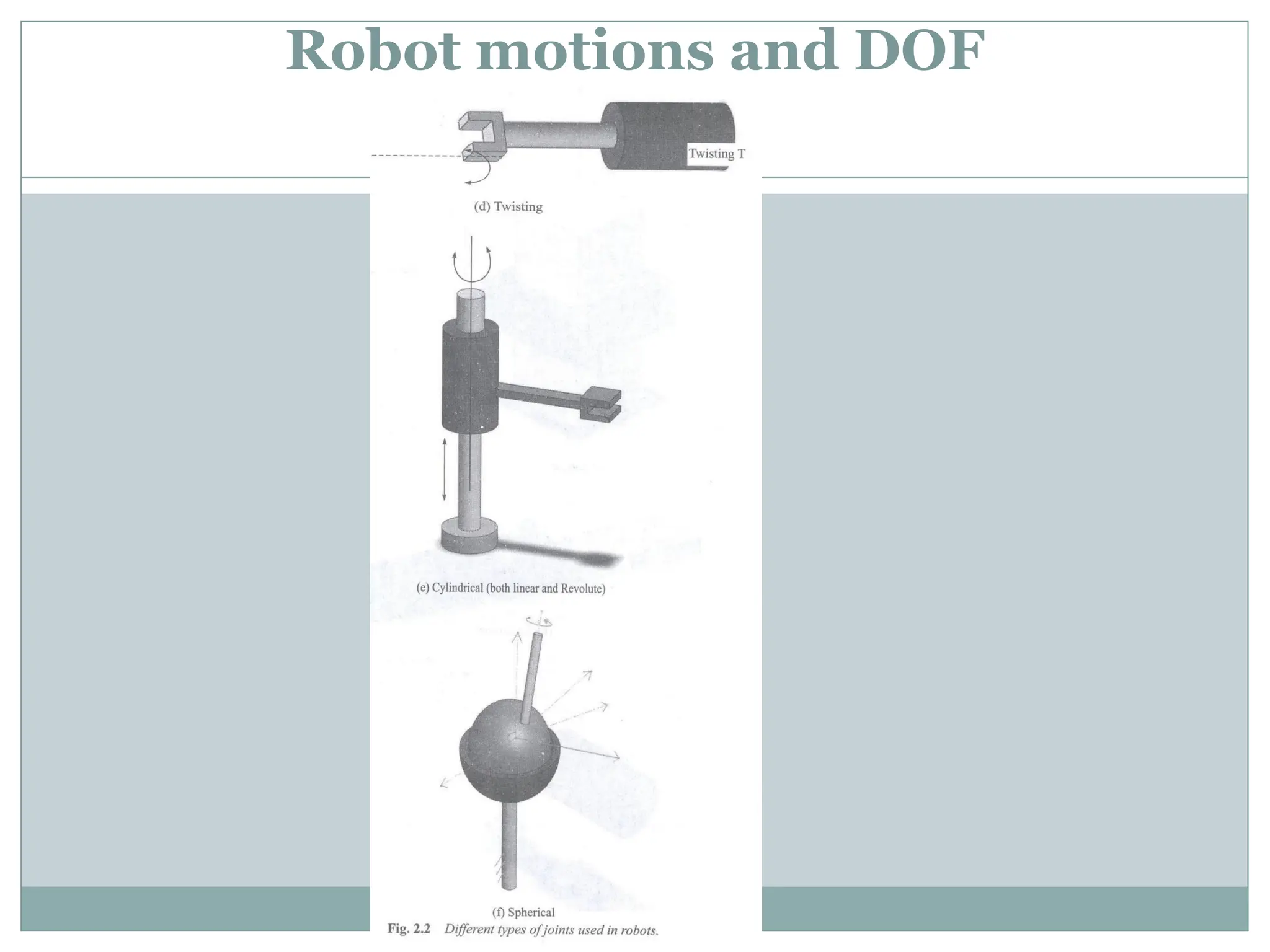

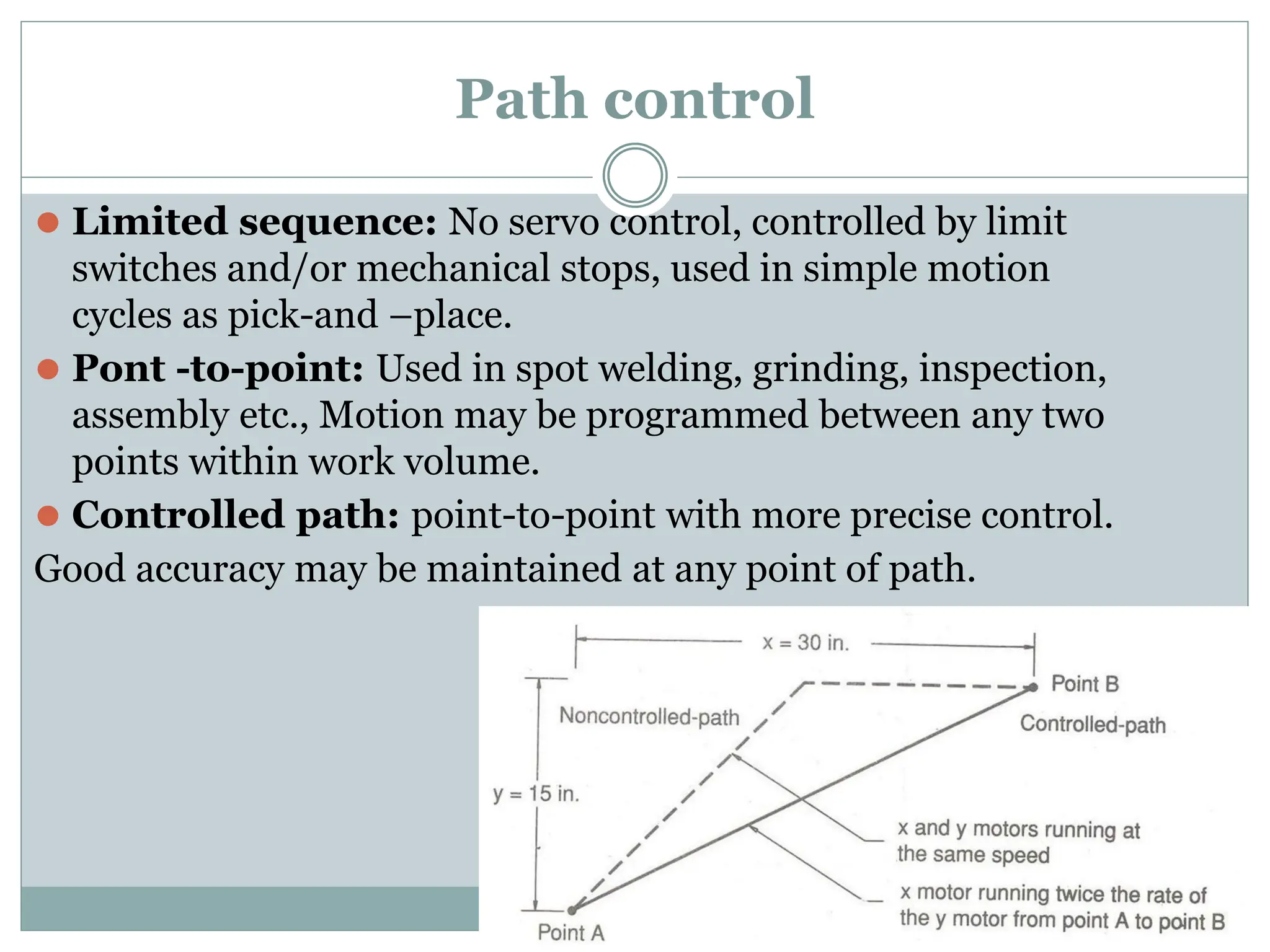

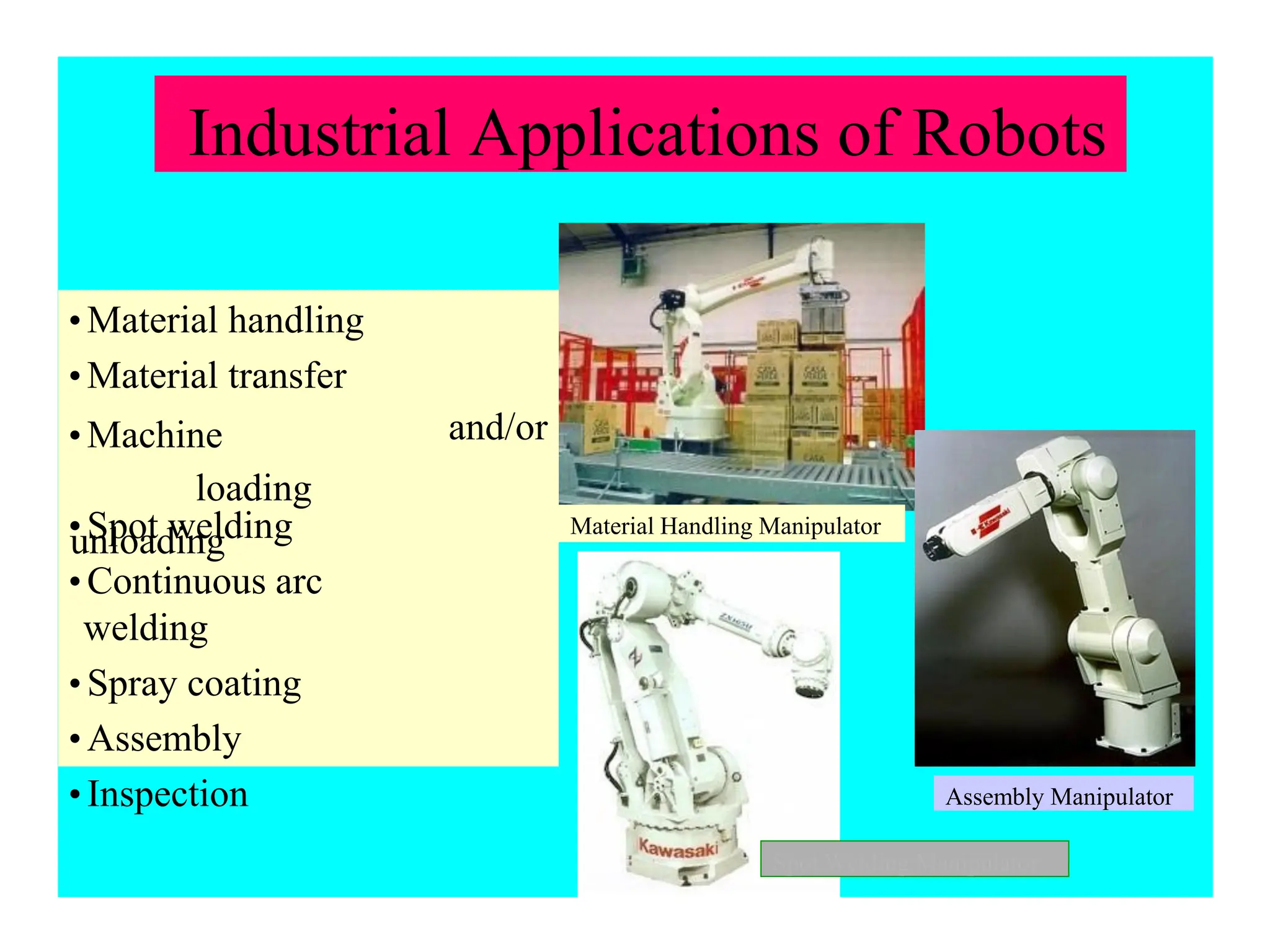

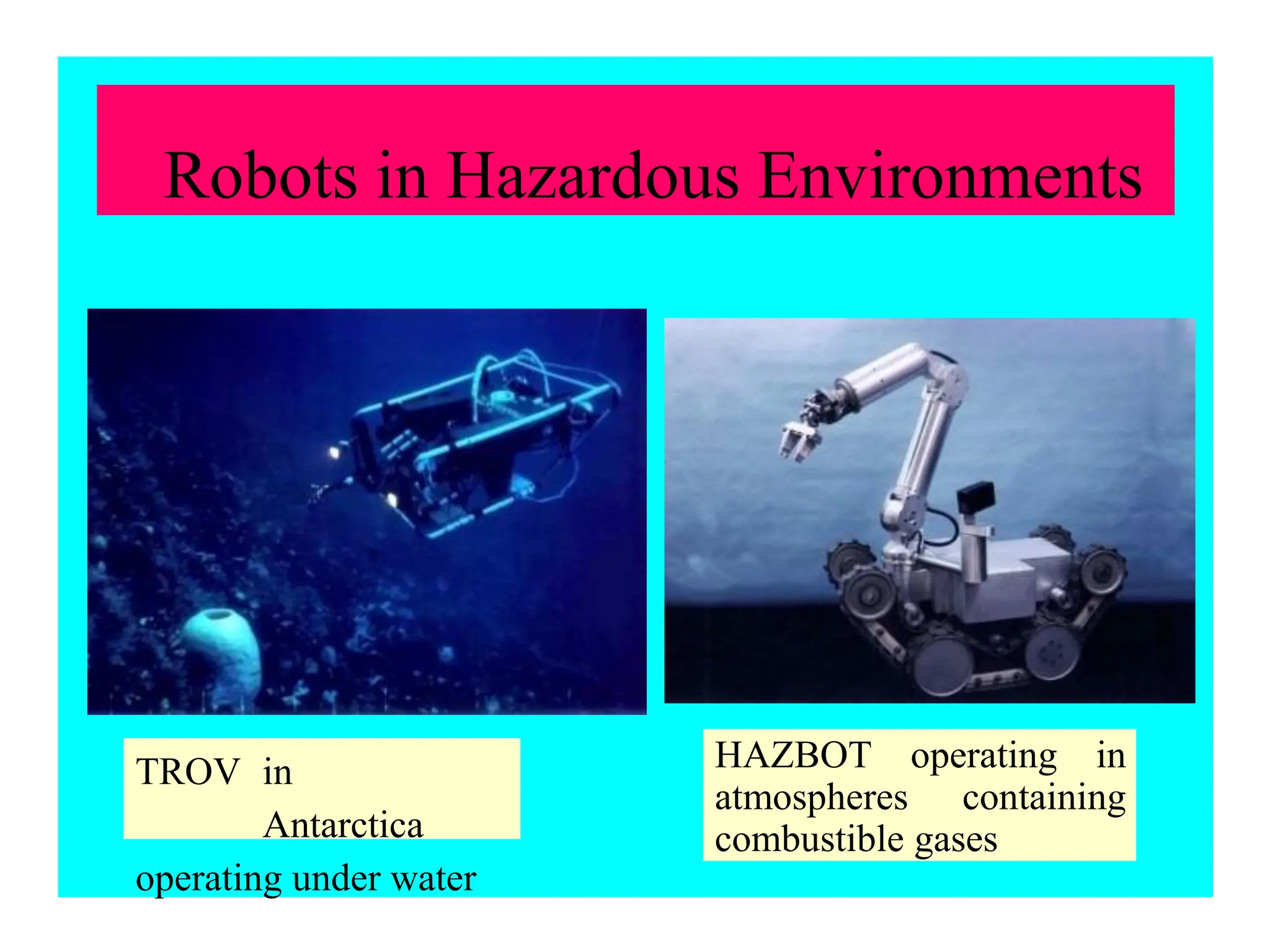

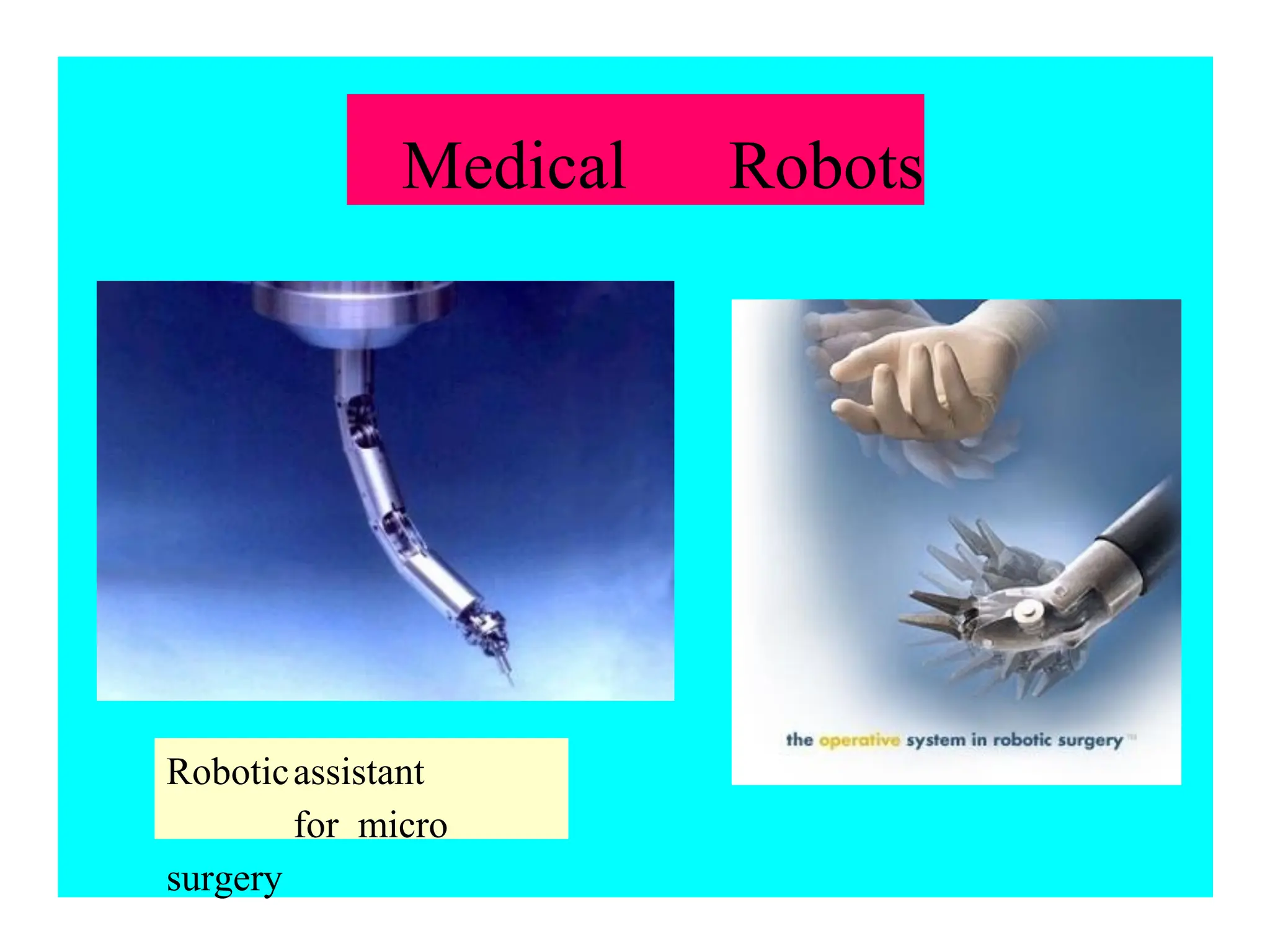

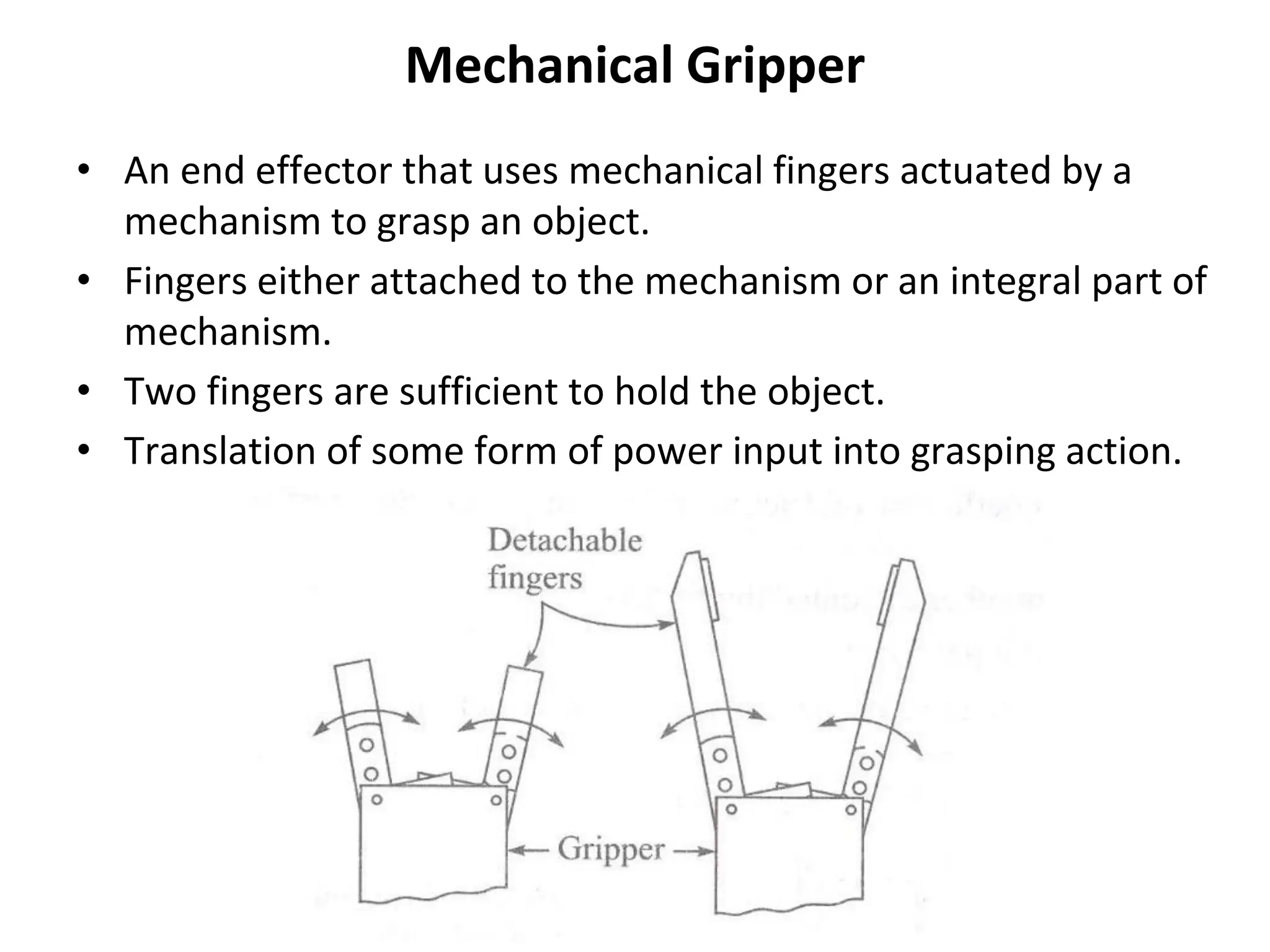

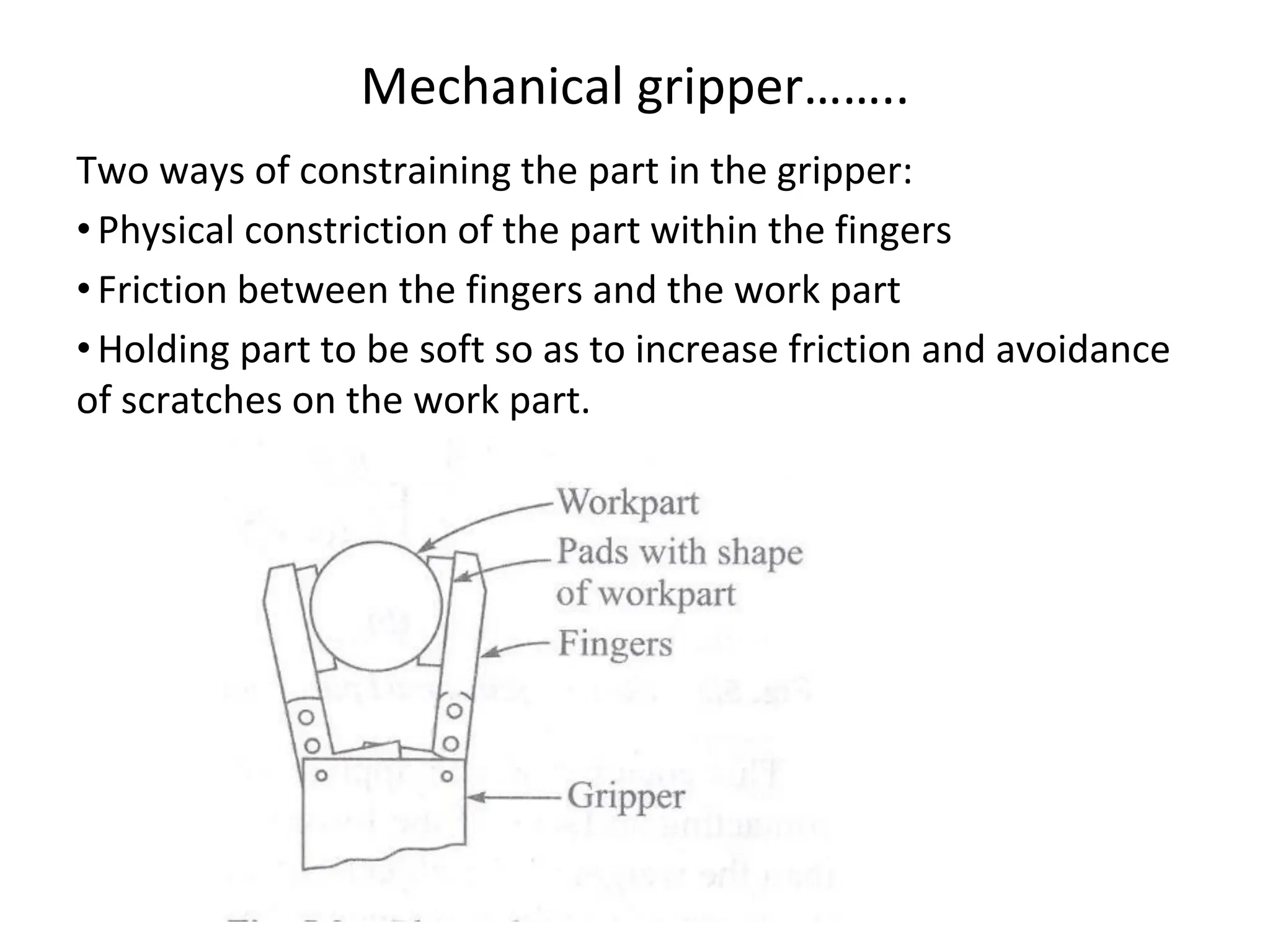

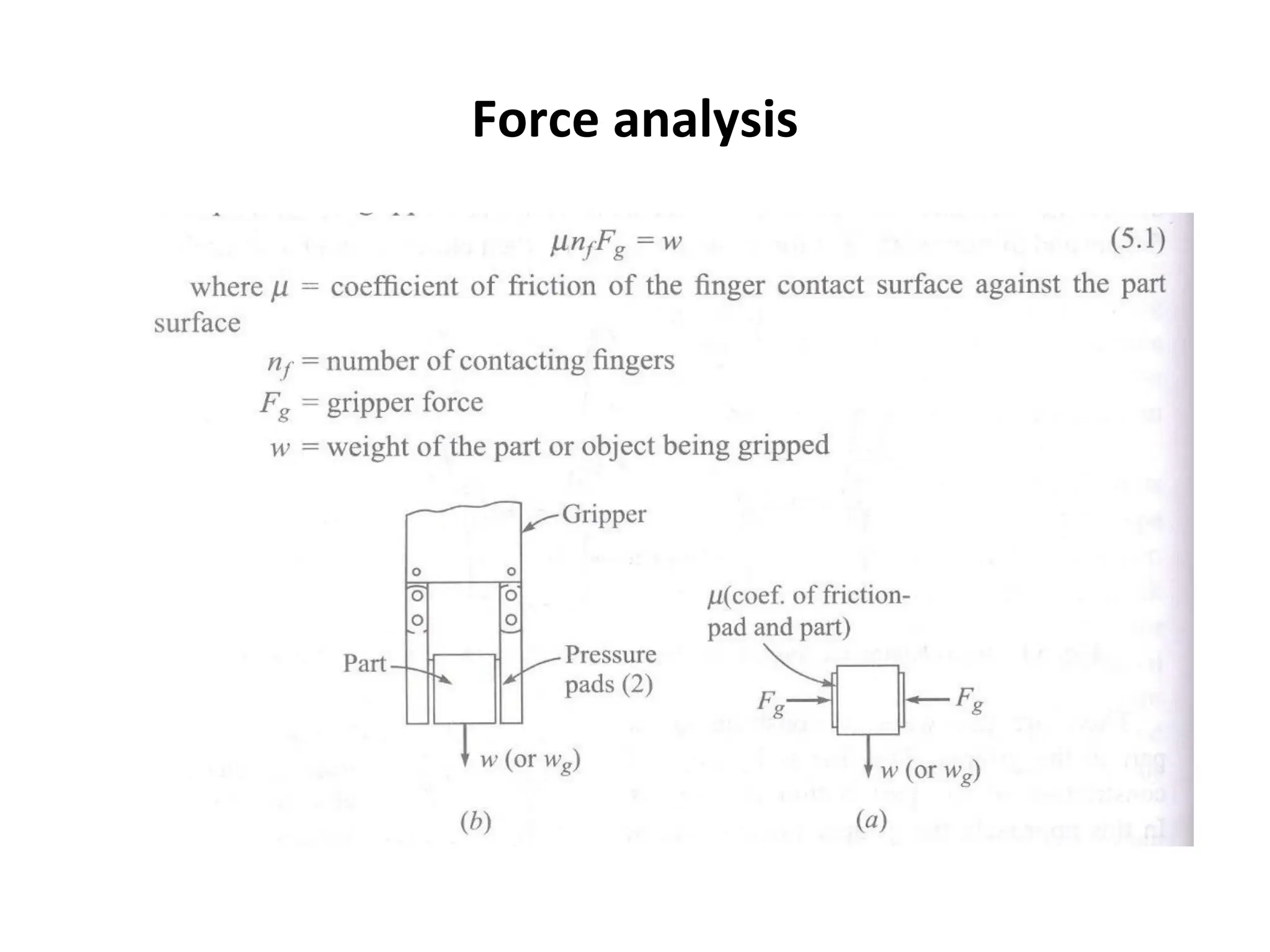

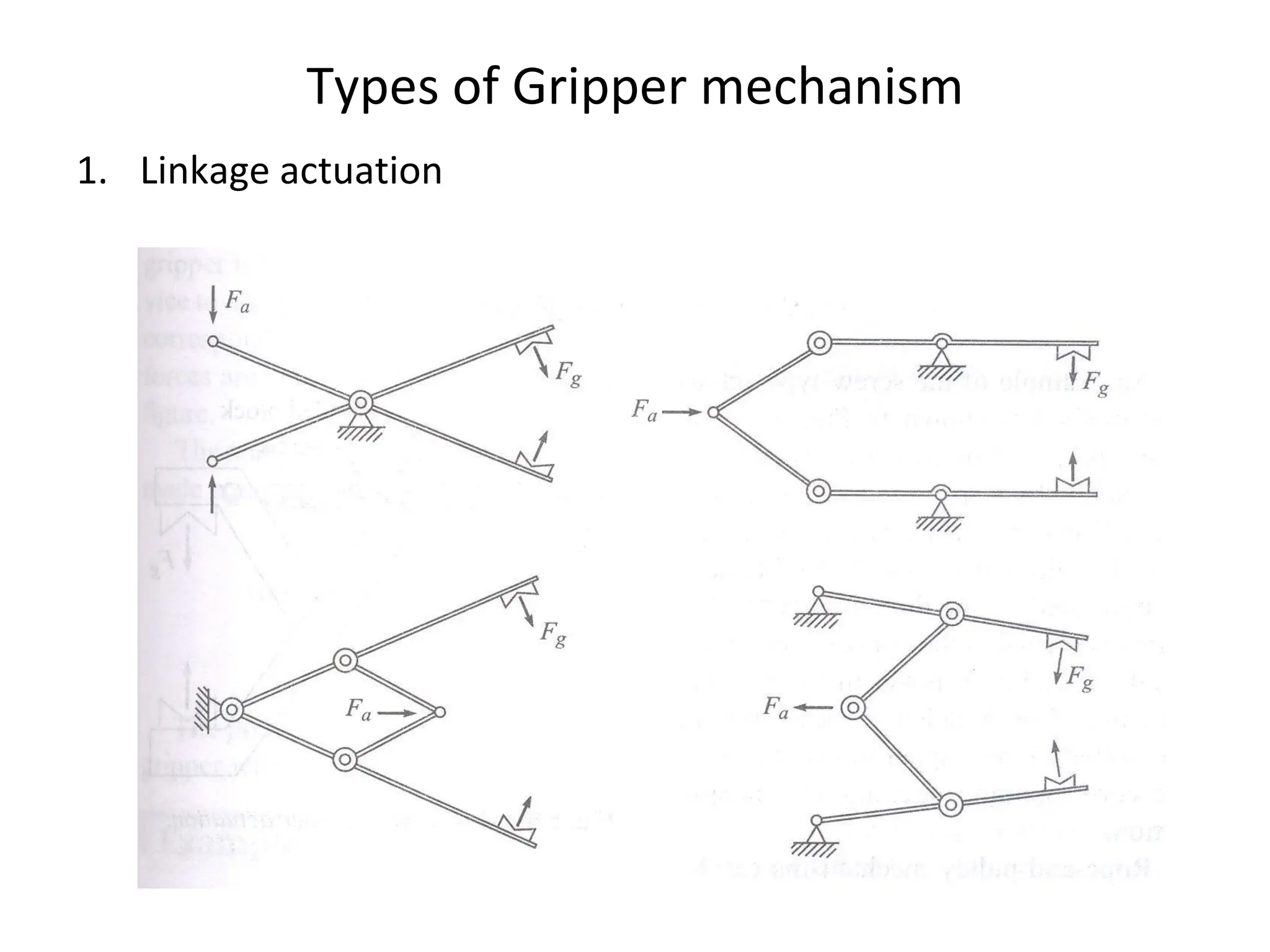

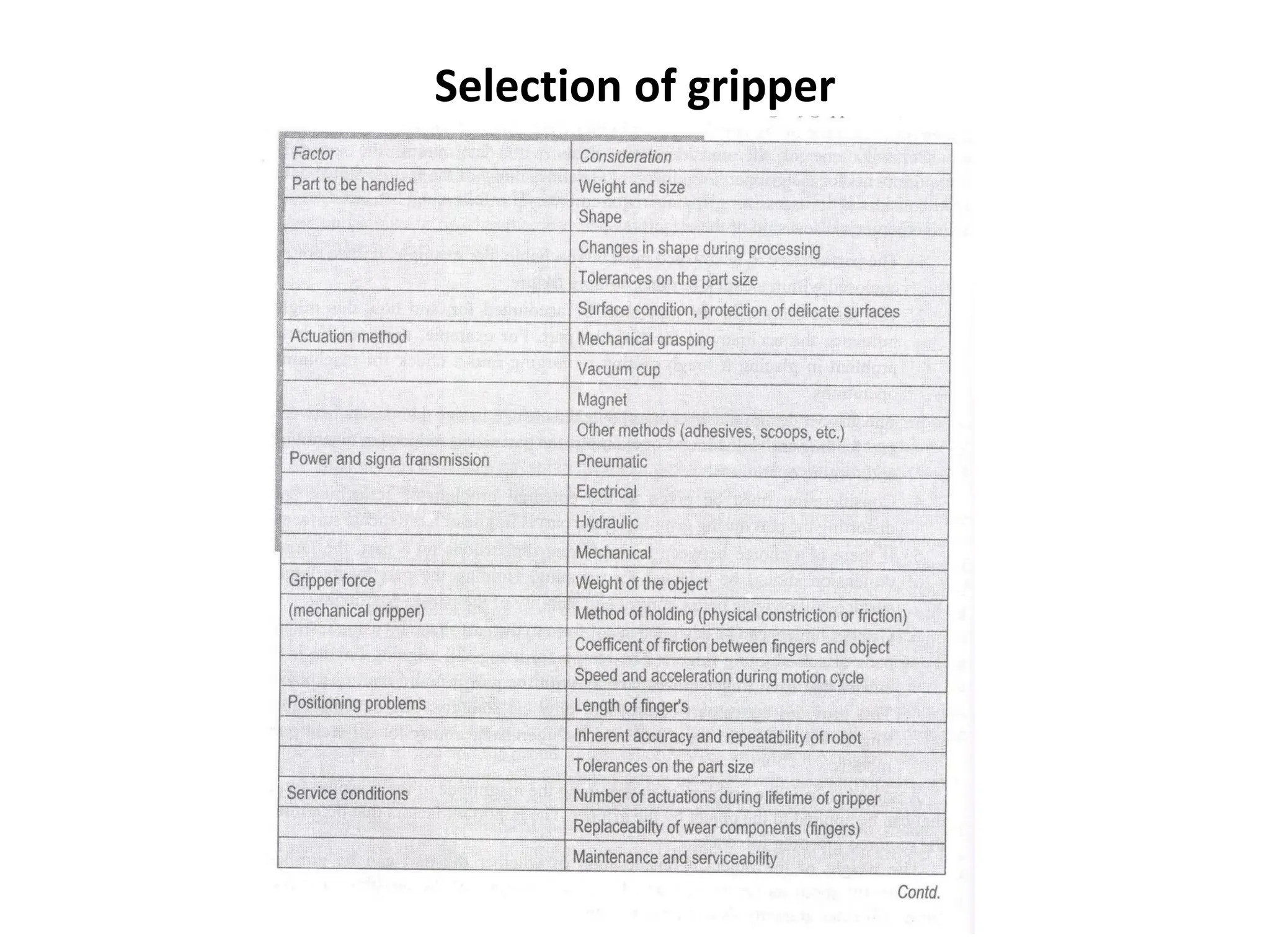

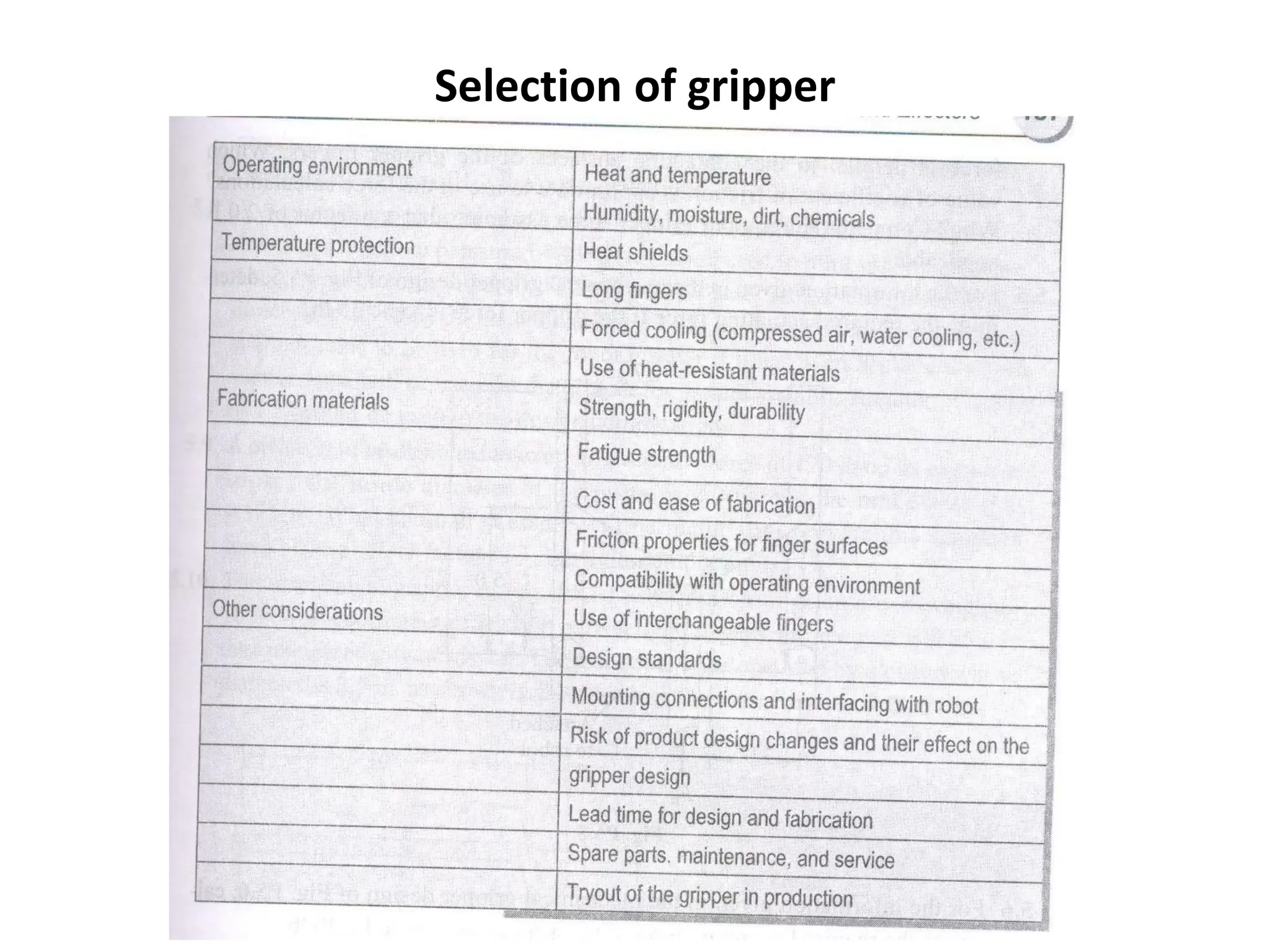

The document provides a comprehensive overview of robots, detailing their definitions, history, components, and classifications. It emphasizes robotics as a multidisciplinary field designed to create autonomous devices capable of performing various tasks, particularly in industrial contexts. Key topics include the laws of robotics, types of robots, their applications in manufacturing and assistive roles, and the technological evolution leading up to modern advancements.