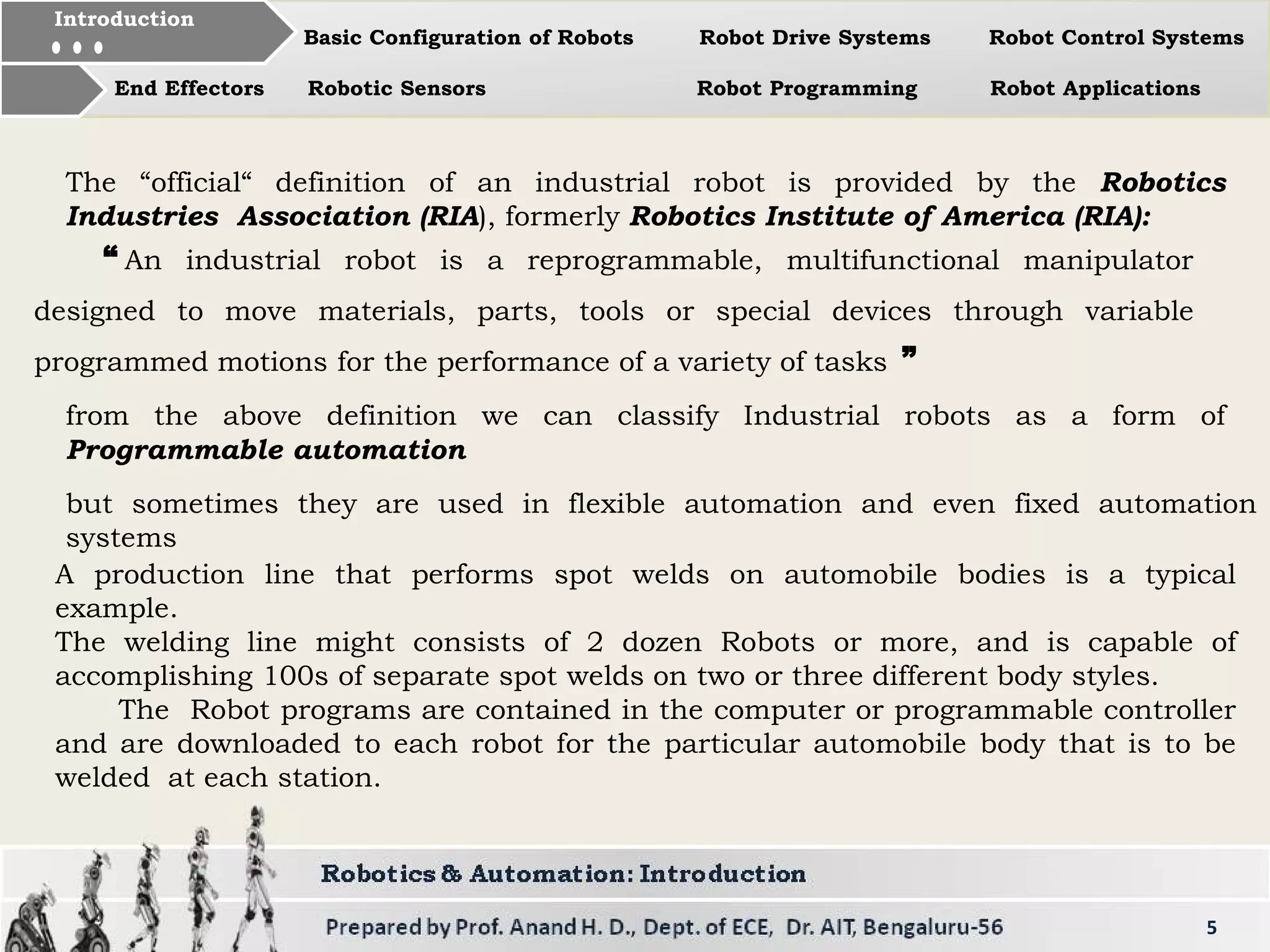

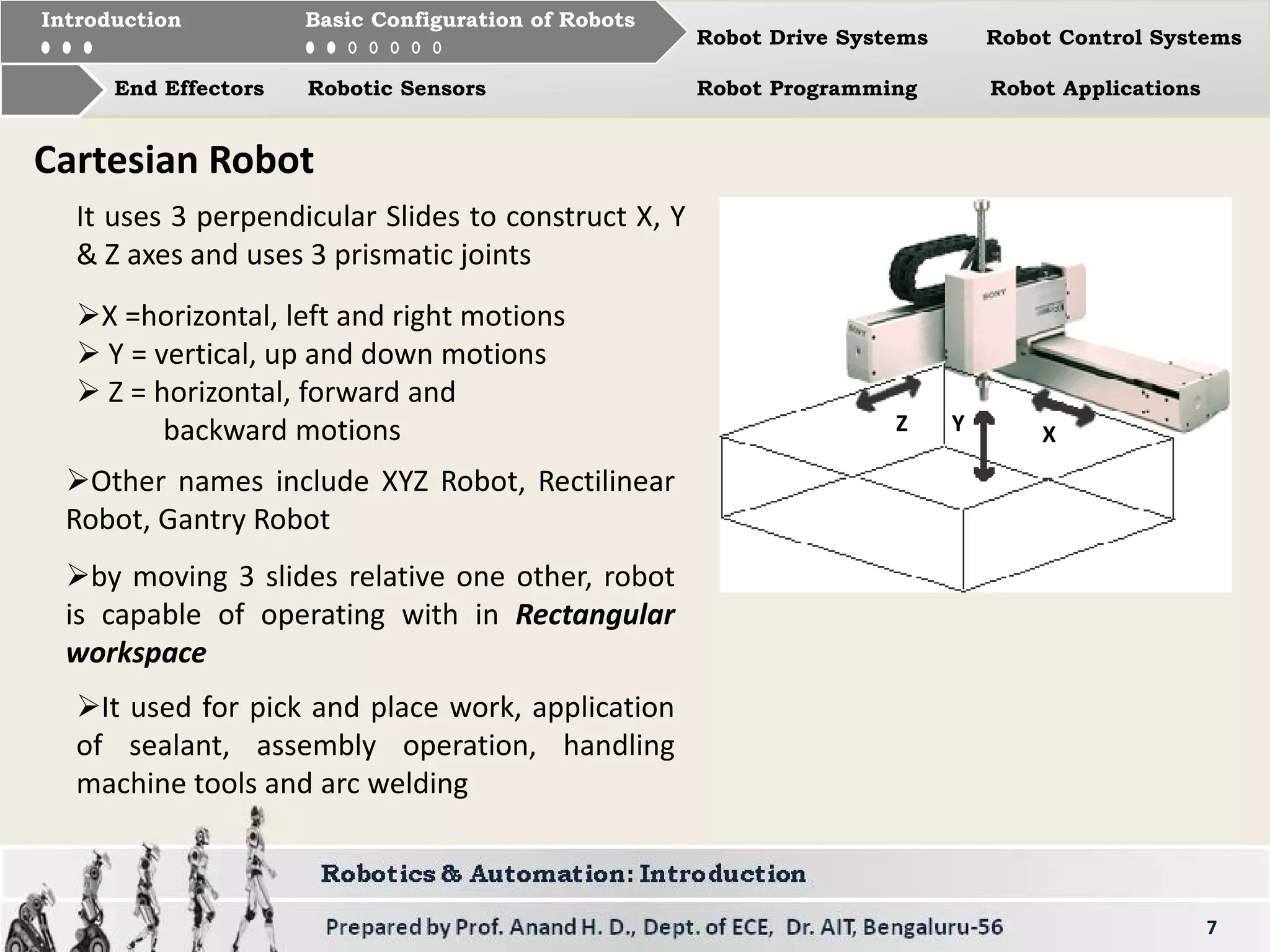

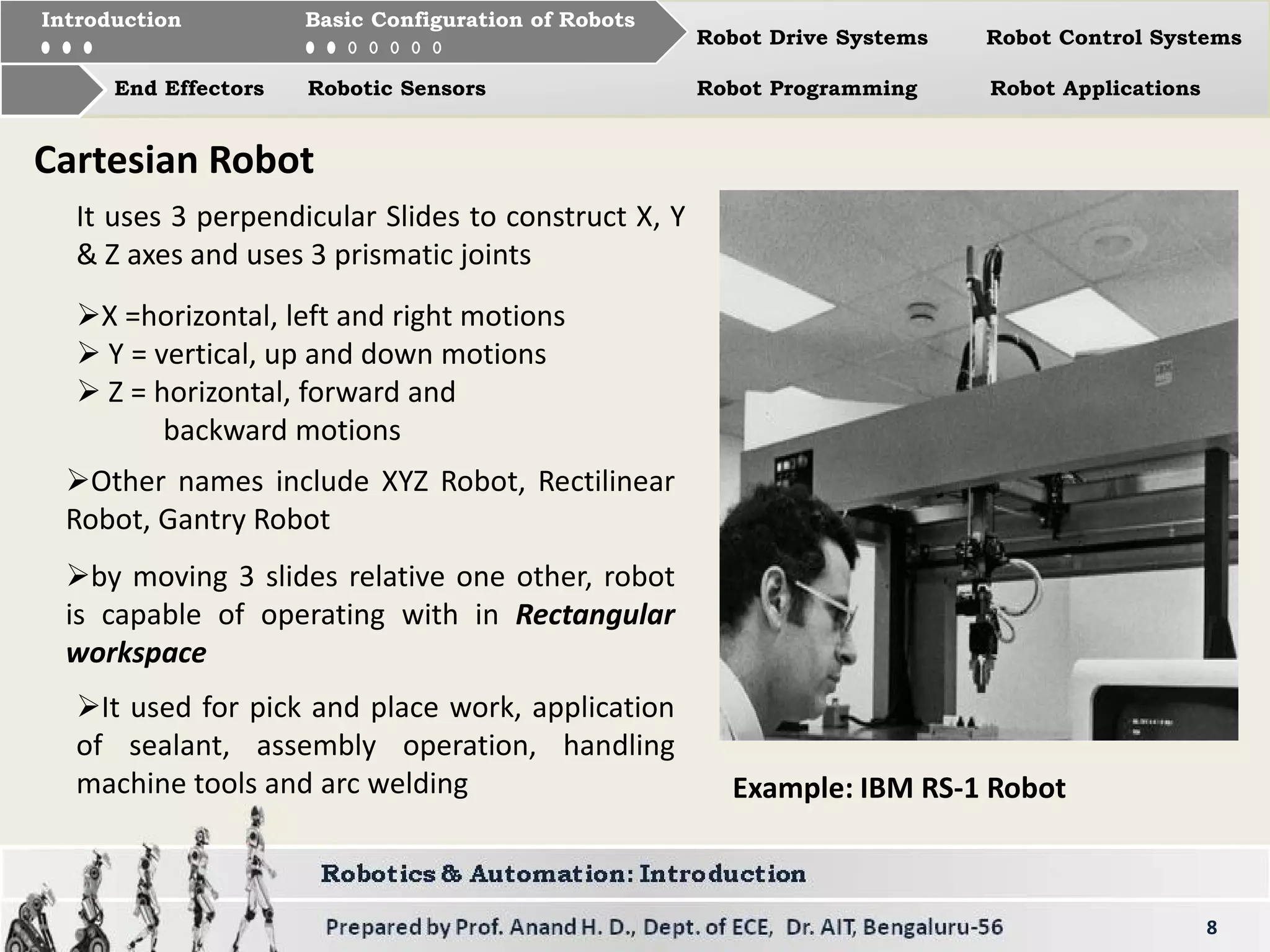

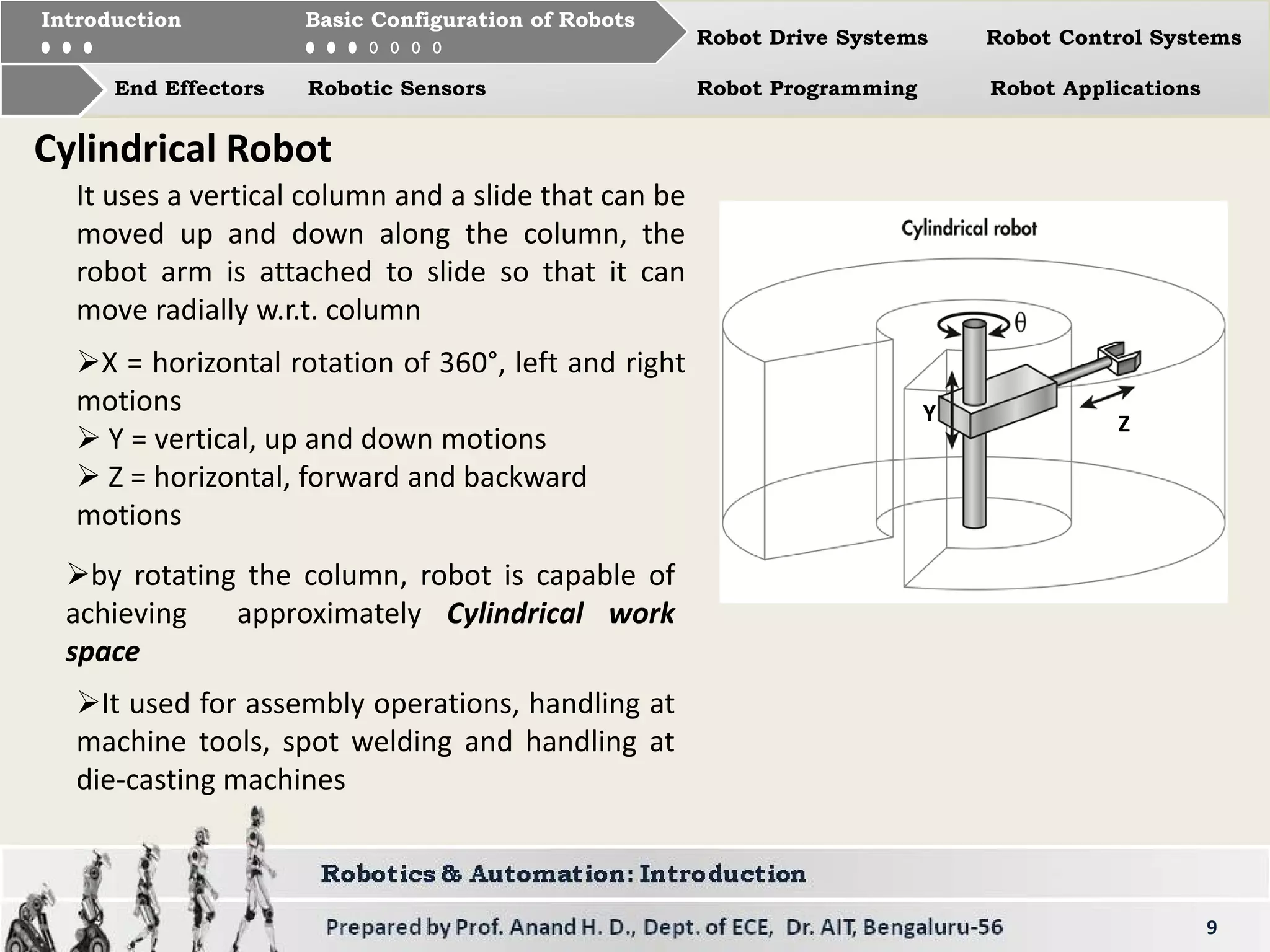

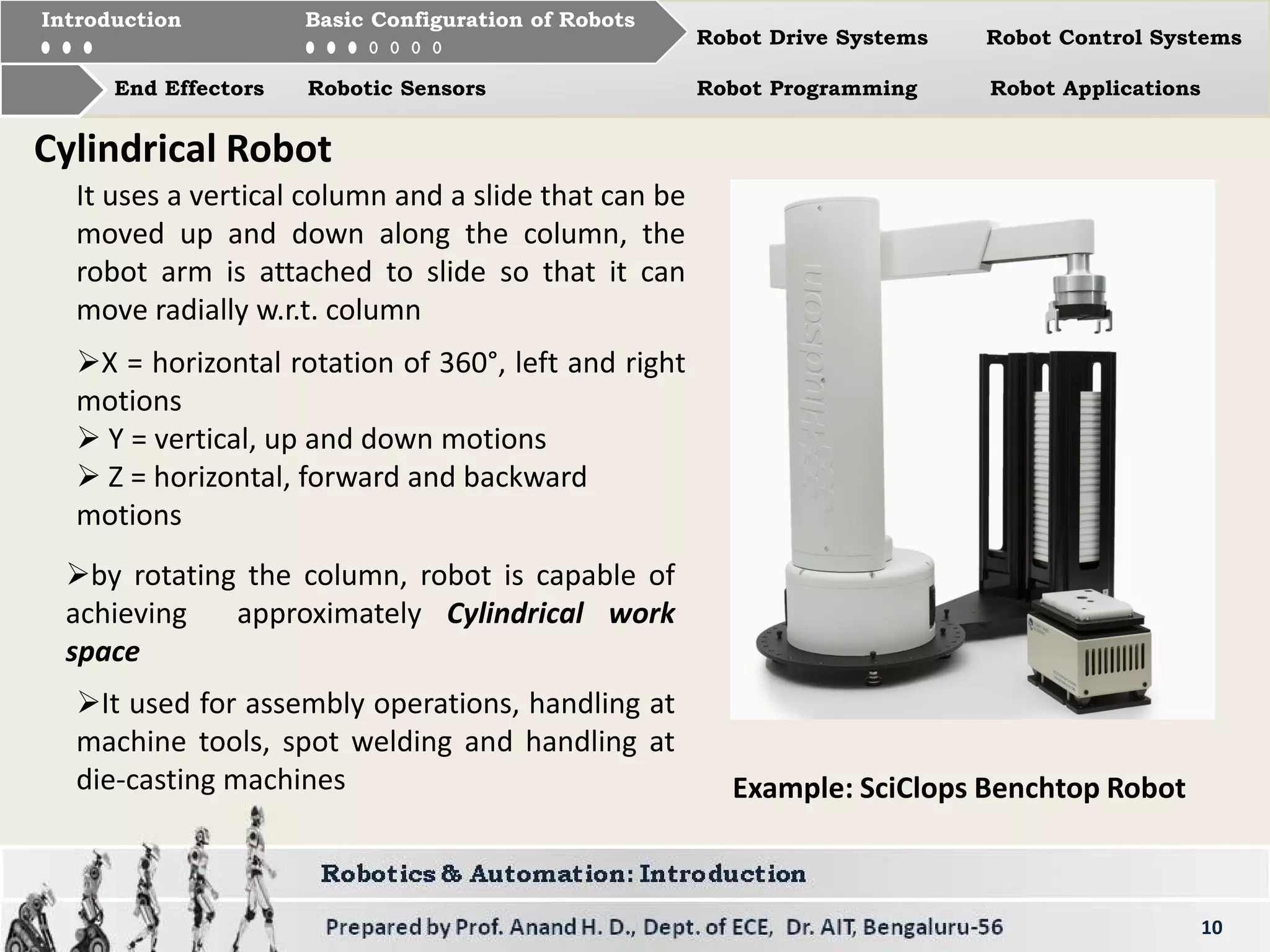

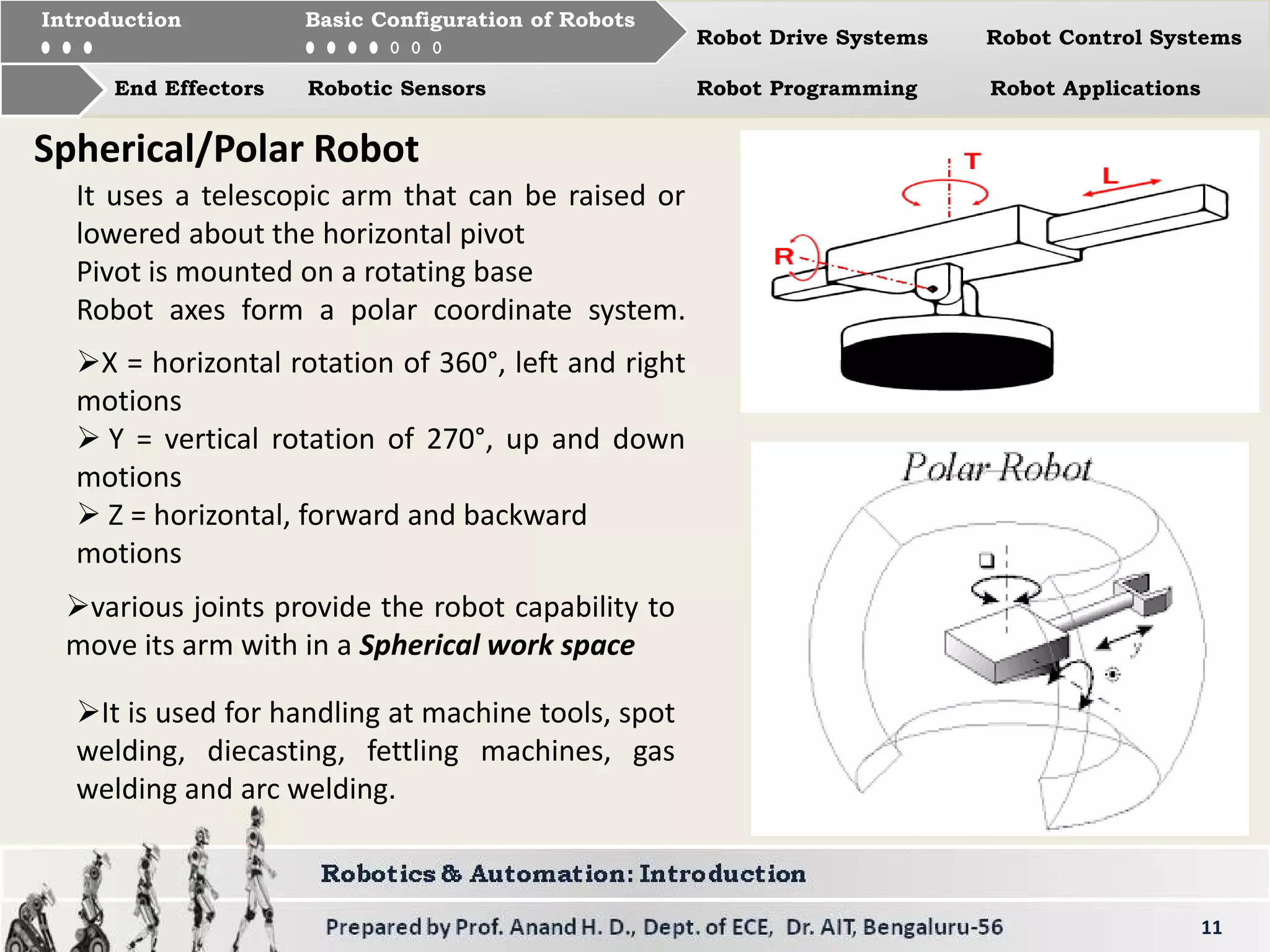

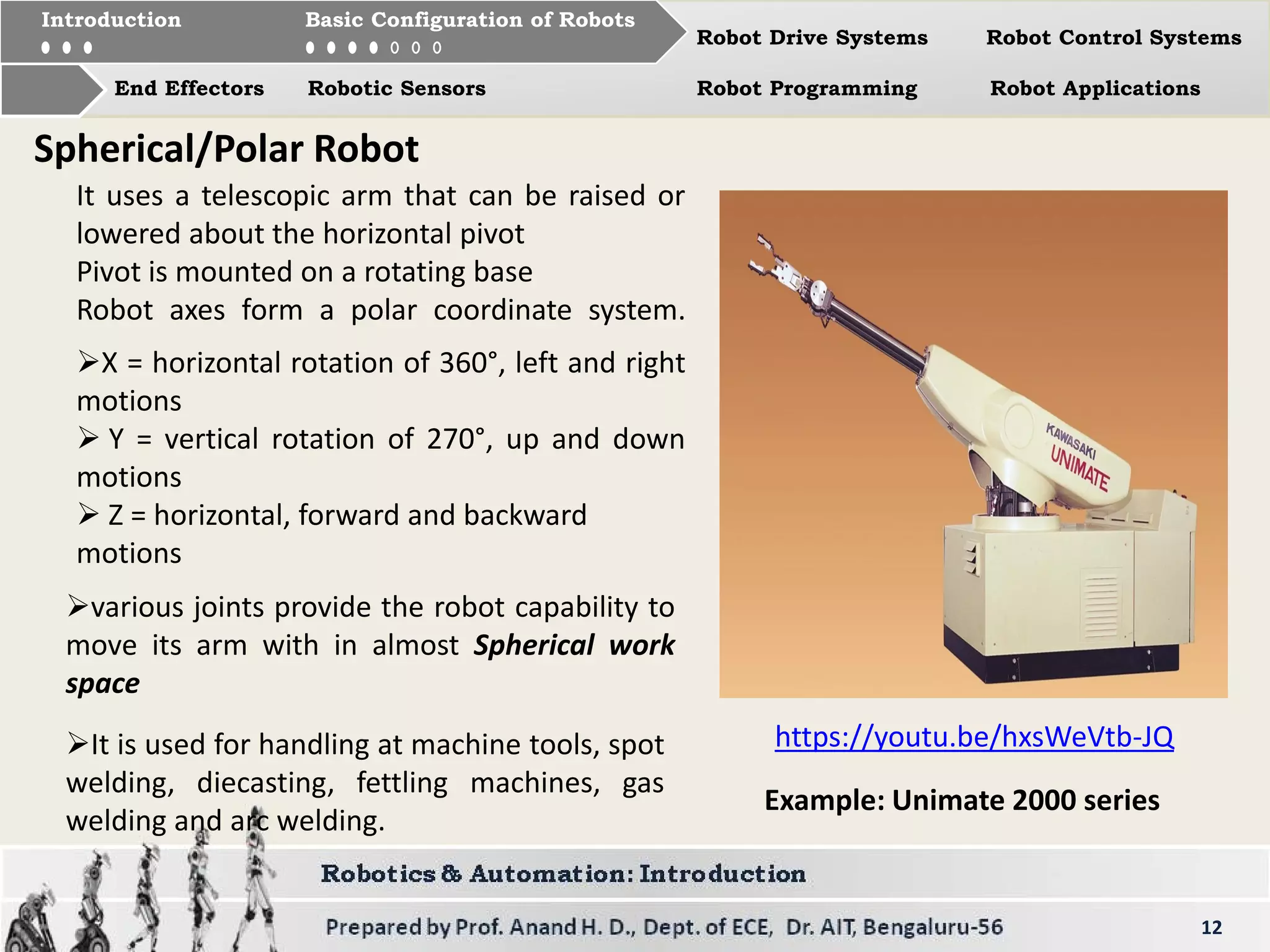

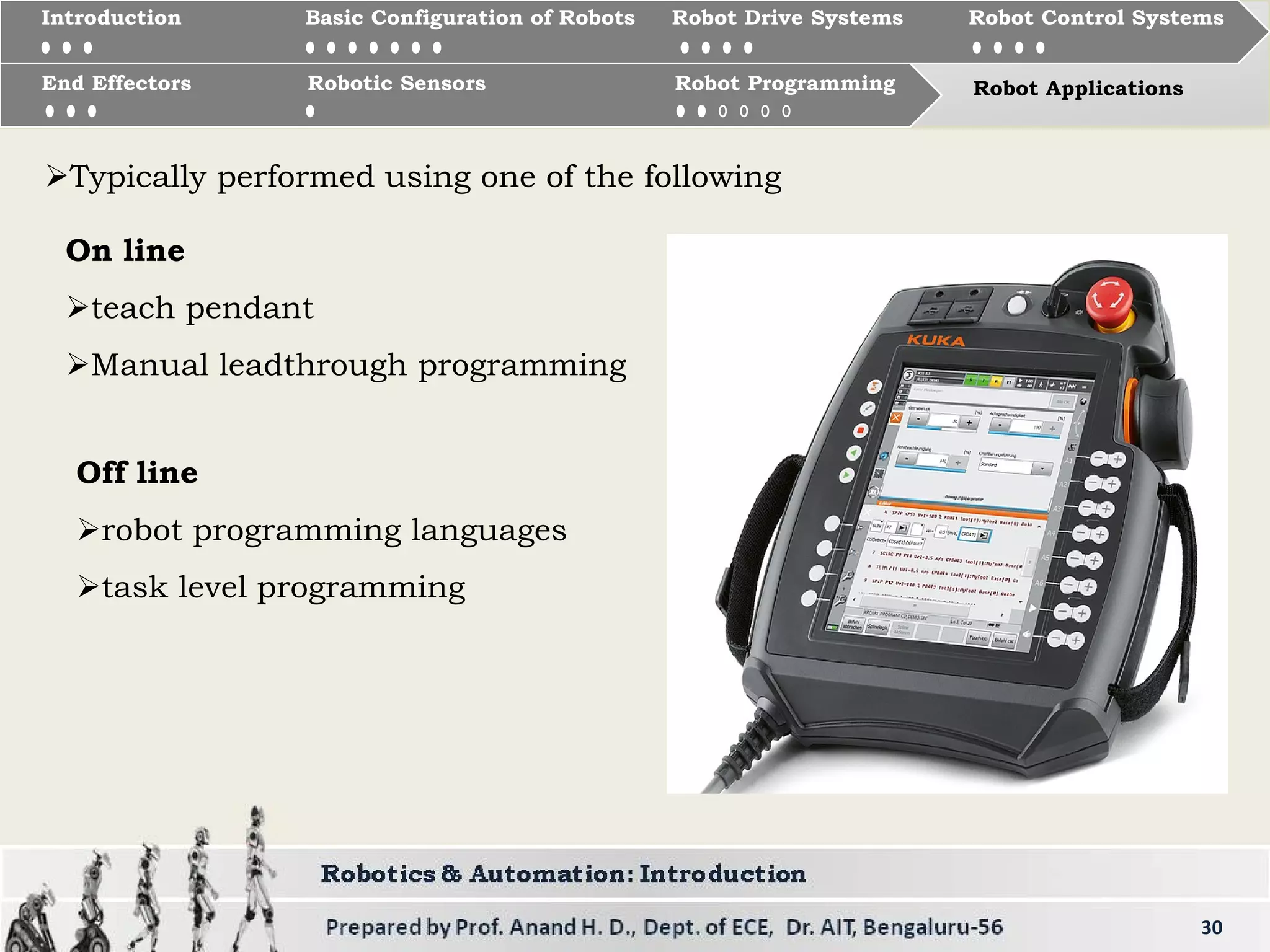

This document provides a comprehensive overview of industrial robotics, covering various components including drive systems, control systems, end effectors, and sensors, as well as applications in automation. It categorizes automation into fixed, programmable, and flexible types, detailing robots' configurations such as Cartesian, cylindrical, and articulated designs, and their respective functionalities. The text also highlights the types of actuators that drive robots, such as electric, hydraulic, and pneumatic systems.