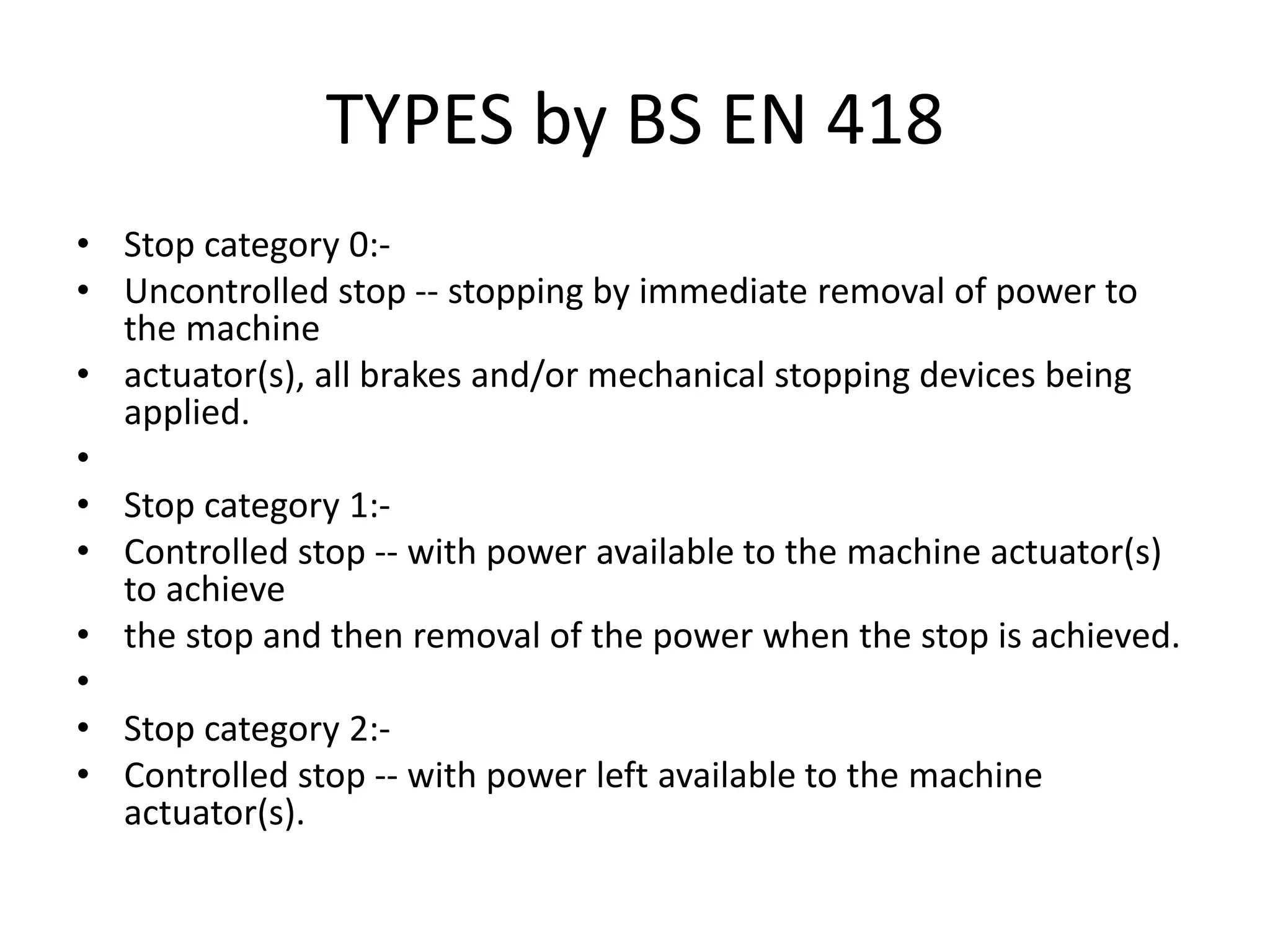

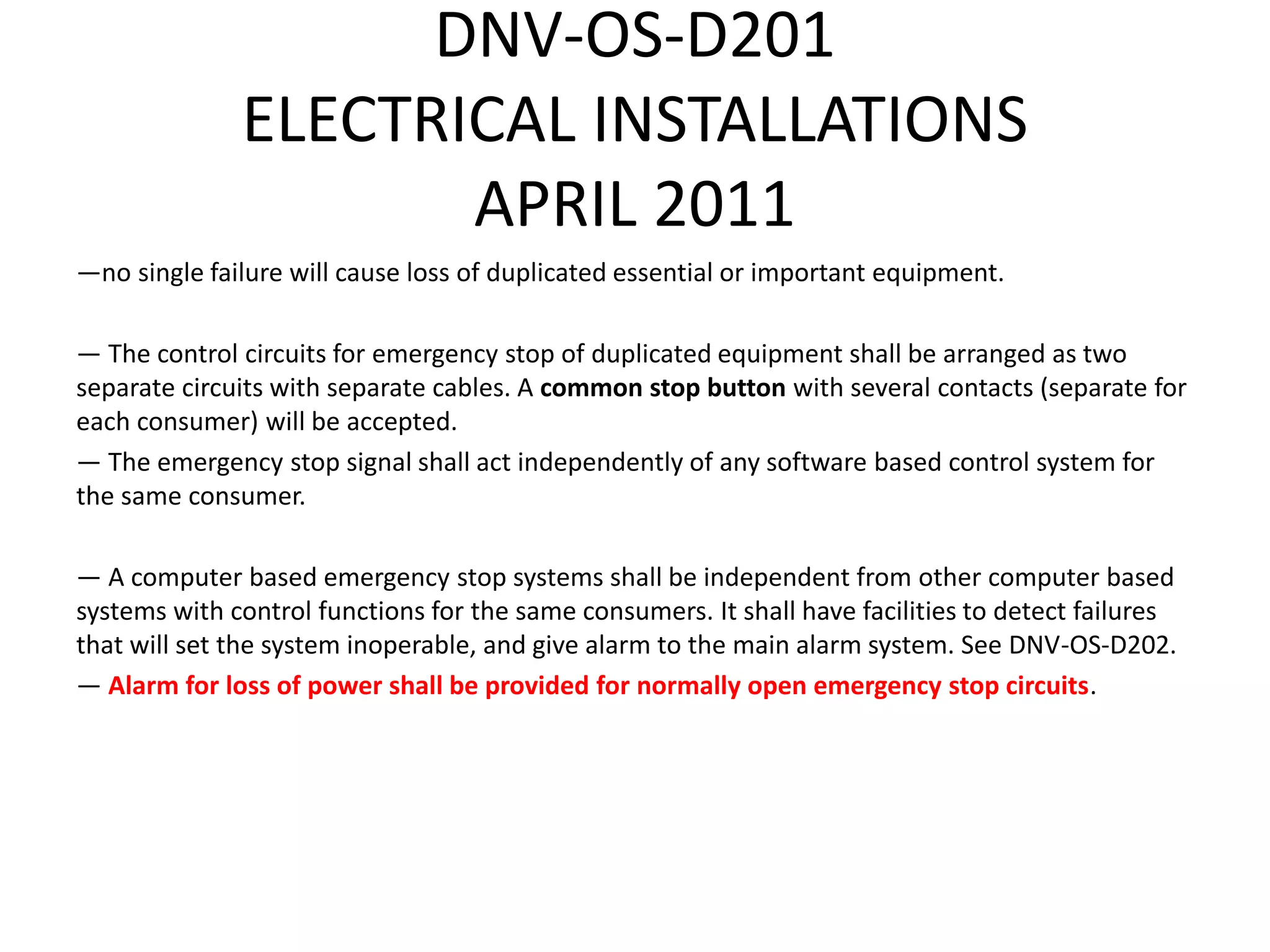

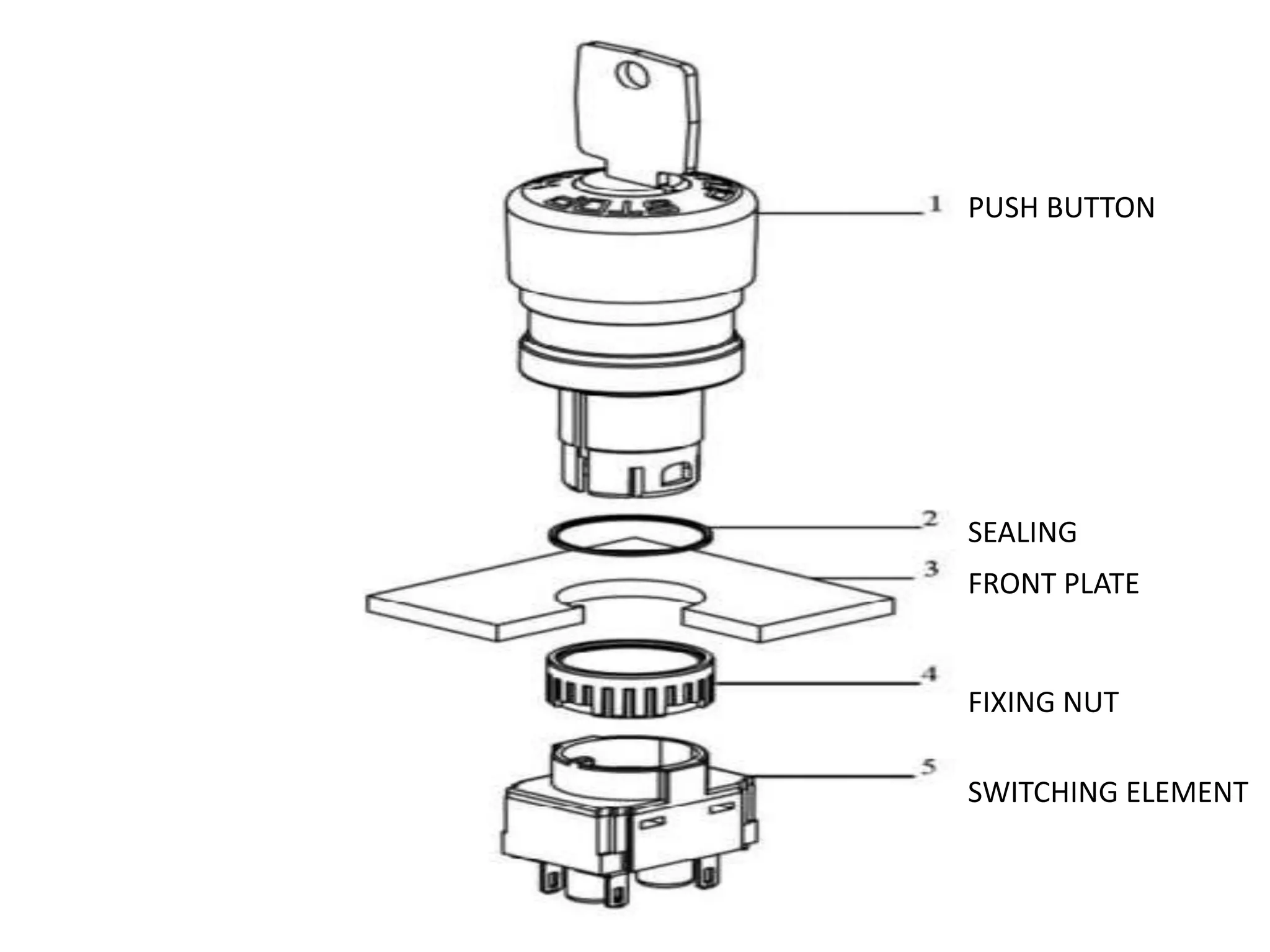

An emergency stop system is intended to avert or reduce hazards to people and equipment. It initiates an immediate shutdown through a single human action when a normal stopping process is not fast enough. Emergency stop buttons are designed for quick, simple activation even by untrained people. They should be located for easy access by operators but not endanger users. Emergency stops can be either uncontrolled power removal stops or controlled power-available stopping, depending on the system and potential hazards. Regulations require redundant, independent emergency stop circuits to ensure reliable stopping even with single failures.