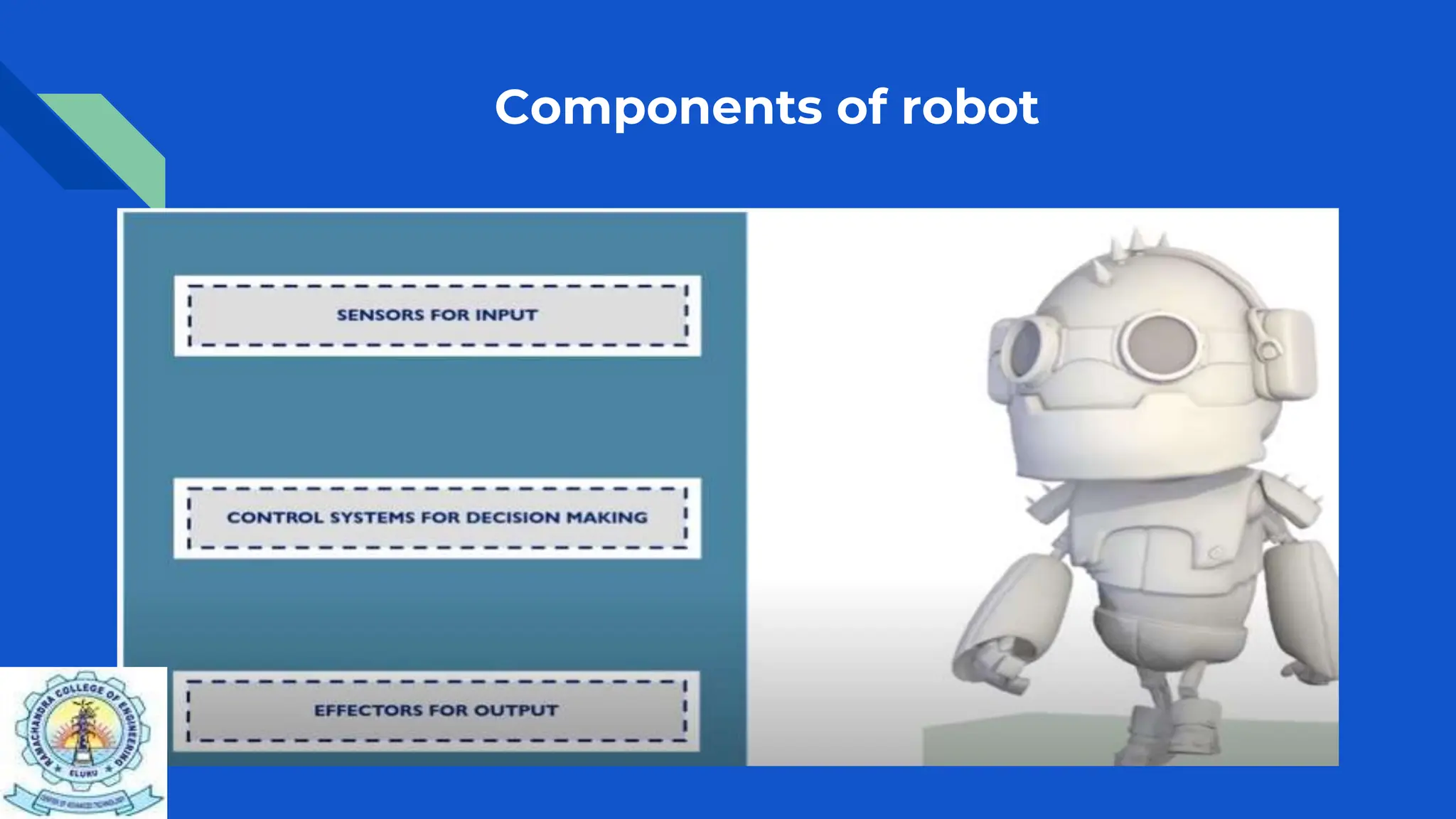

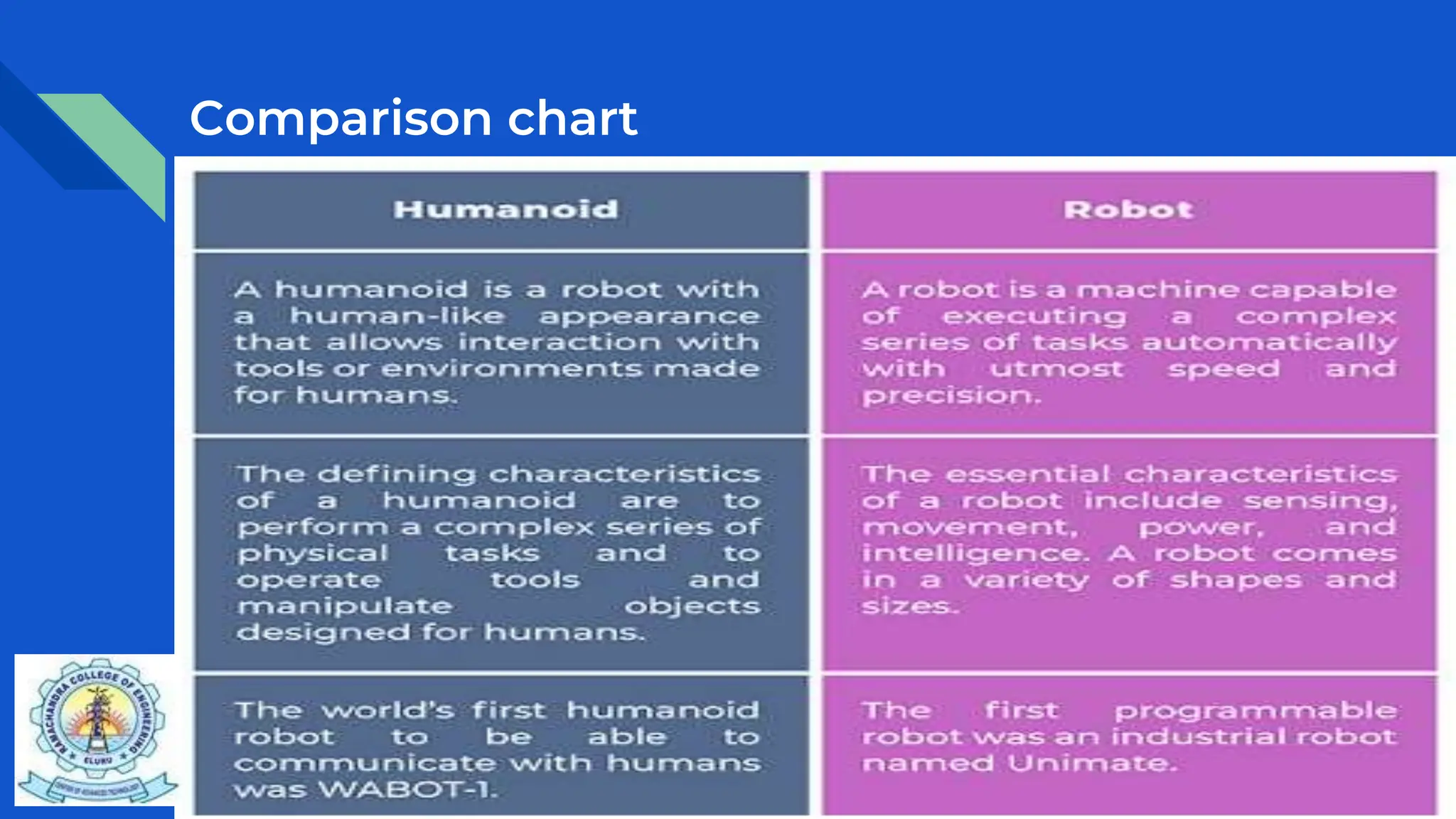

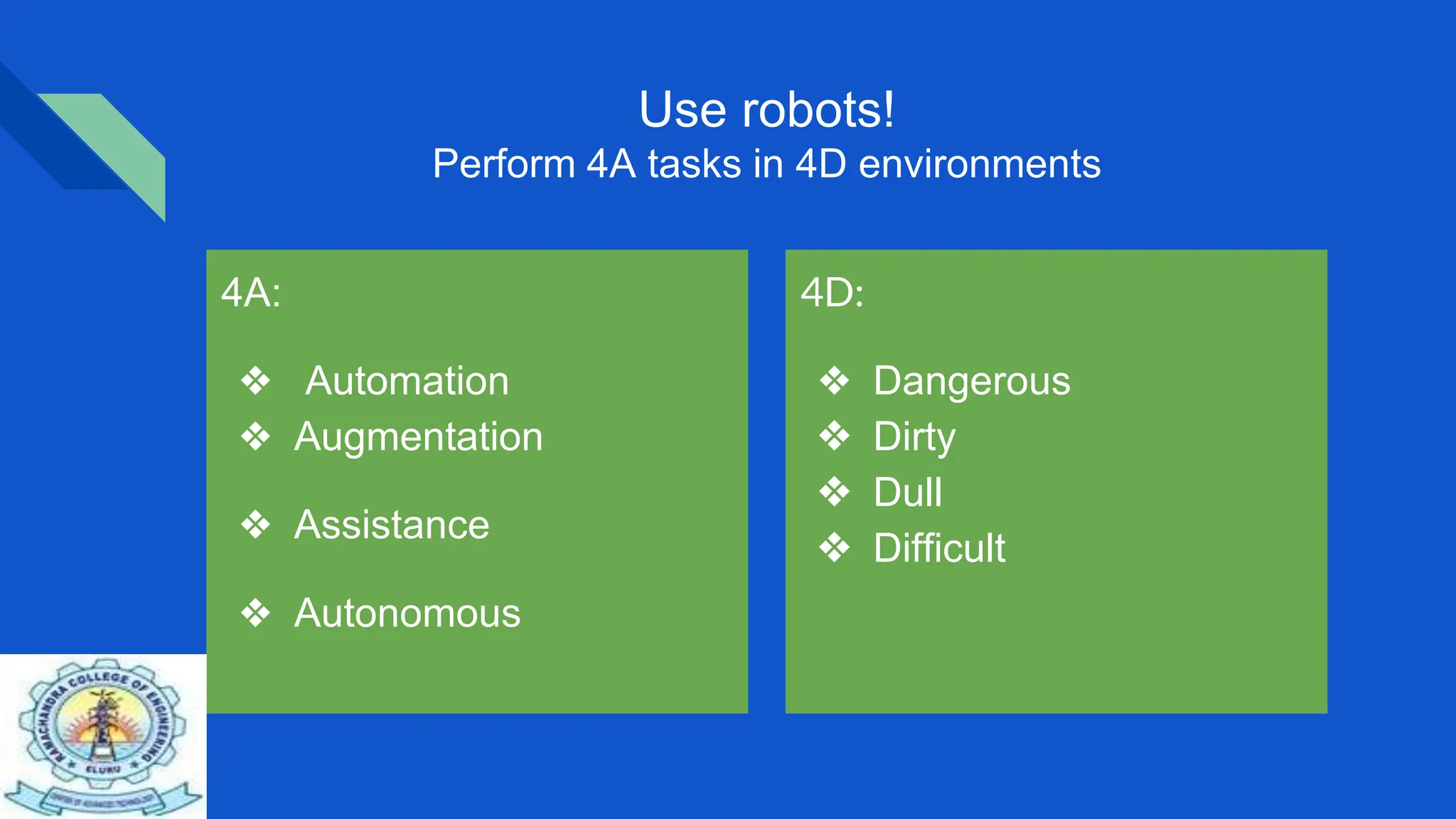

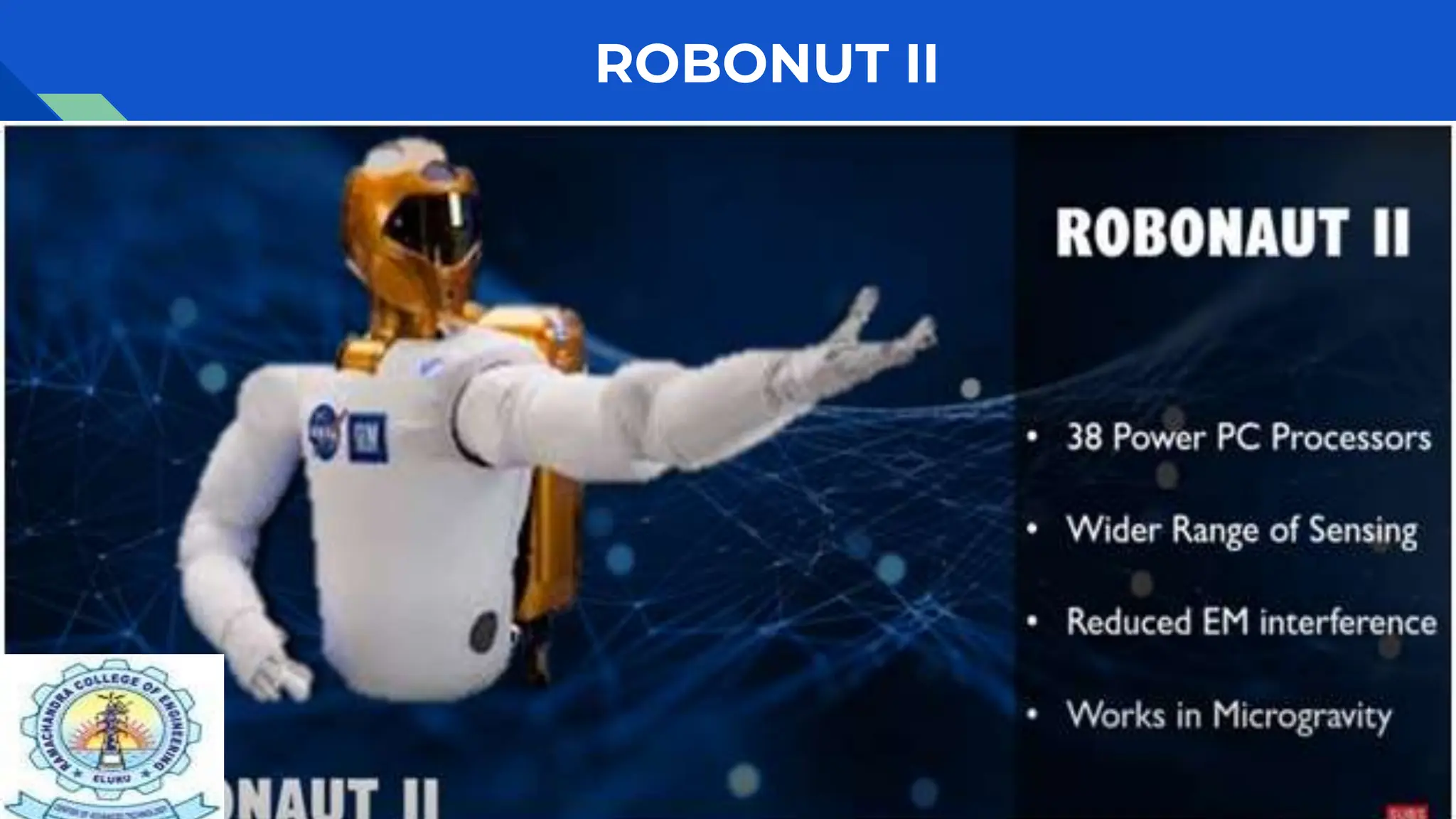

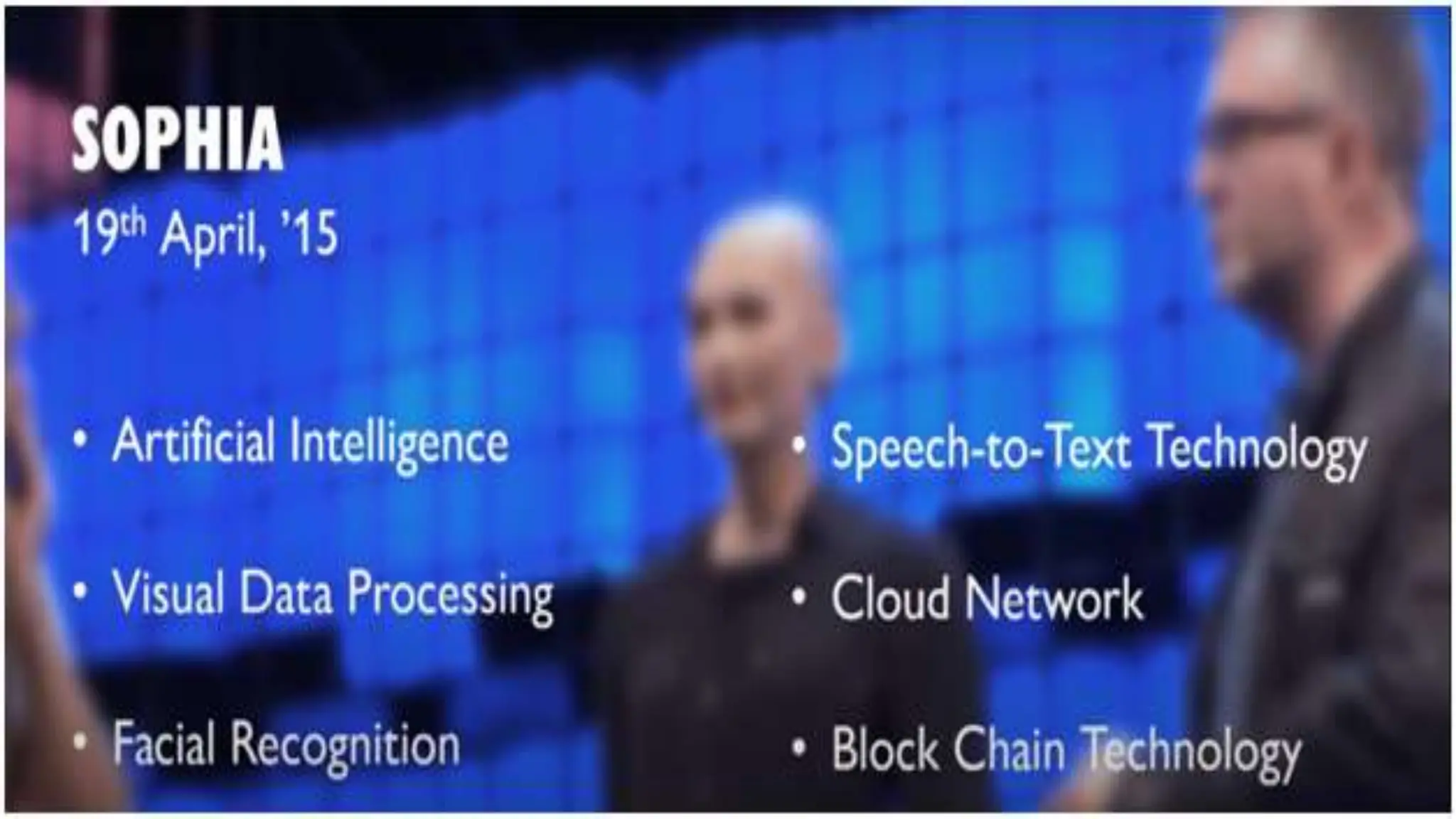

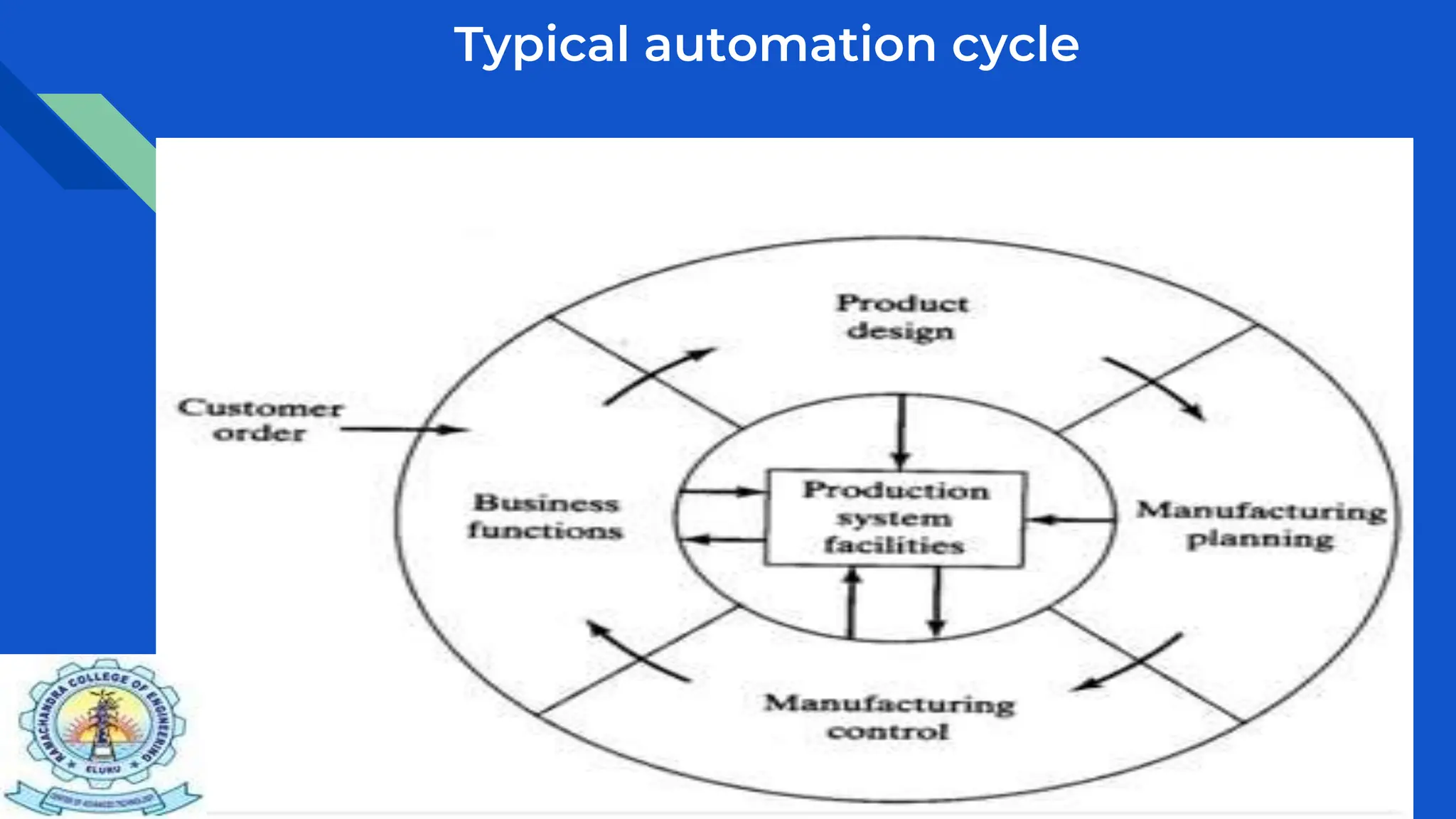

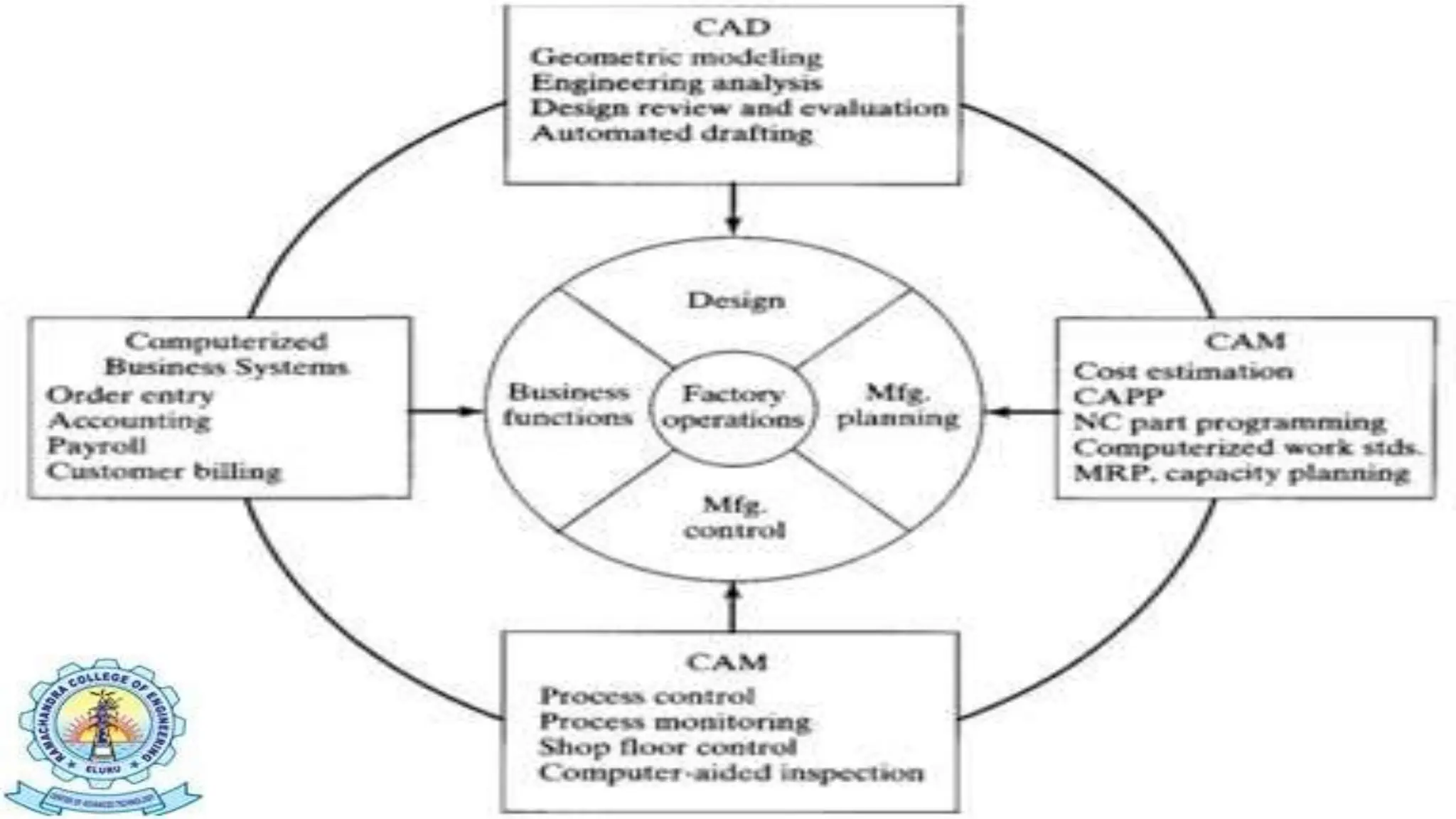

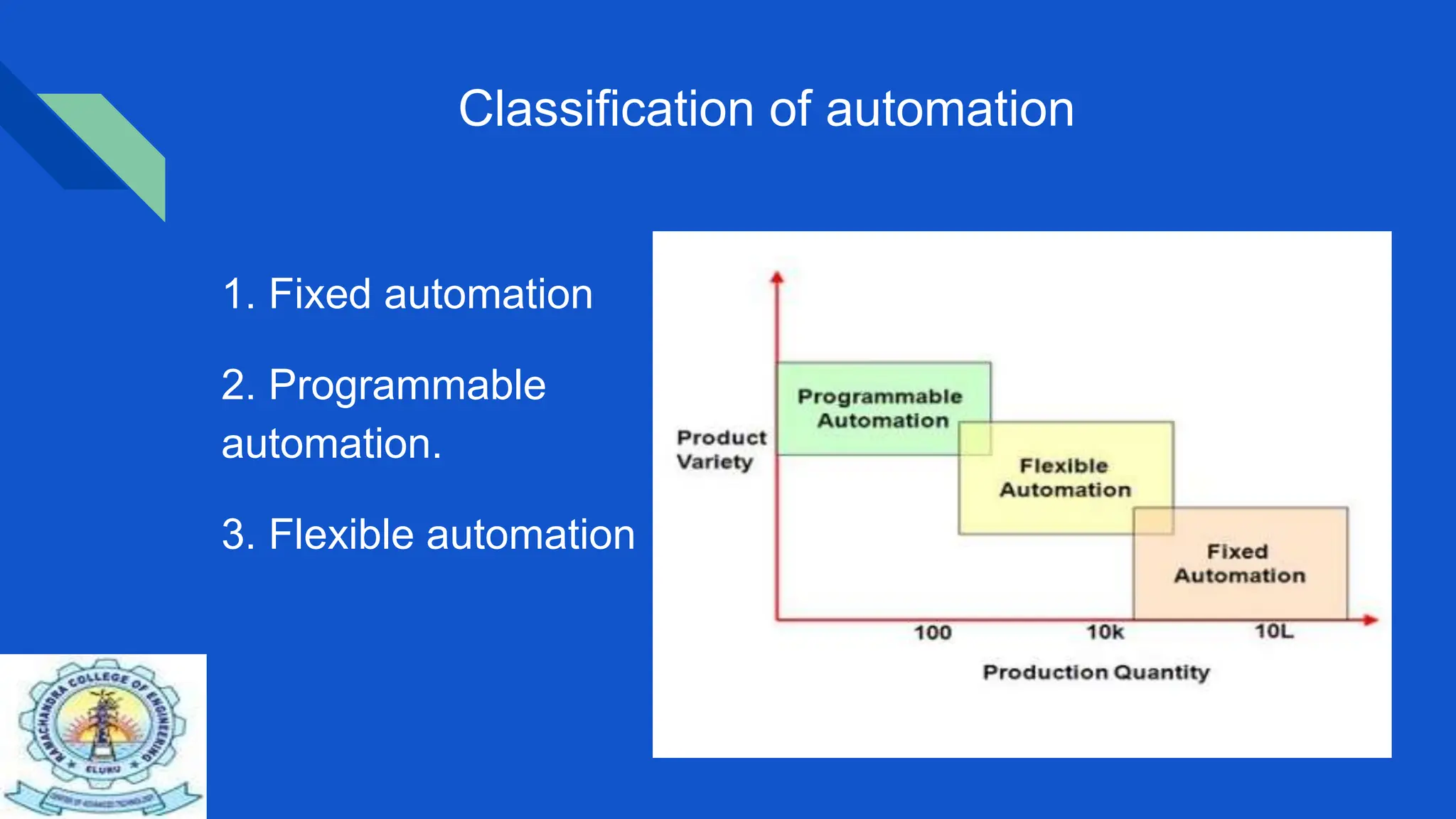

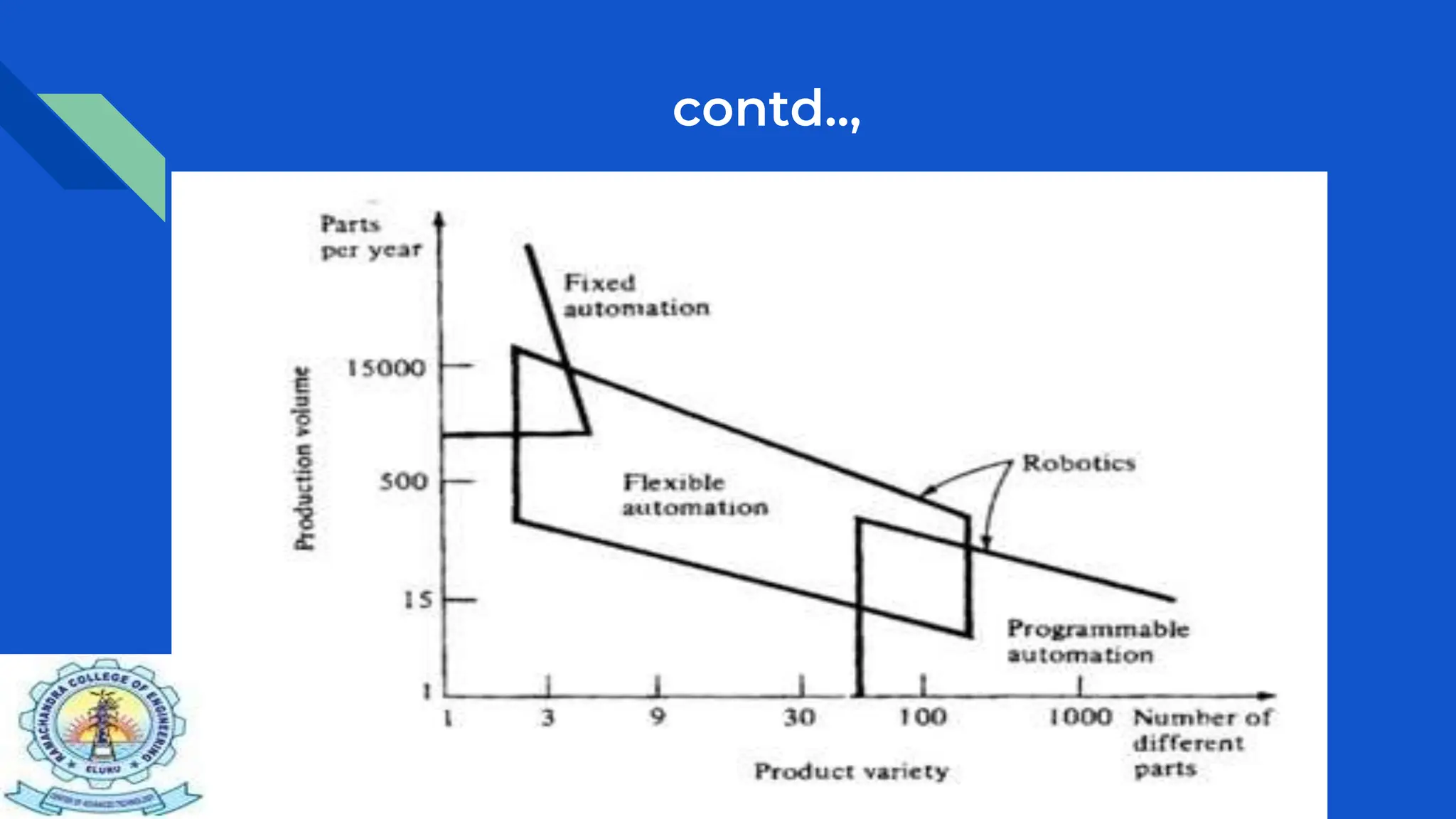

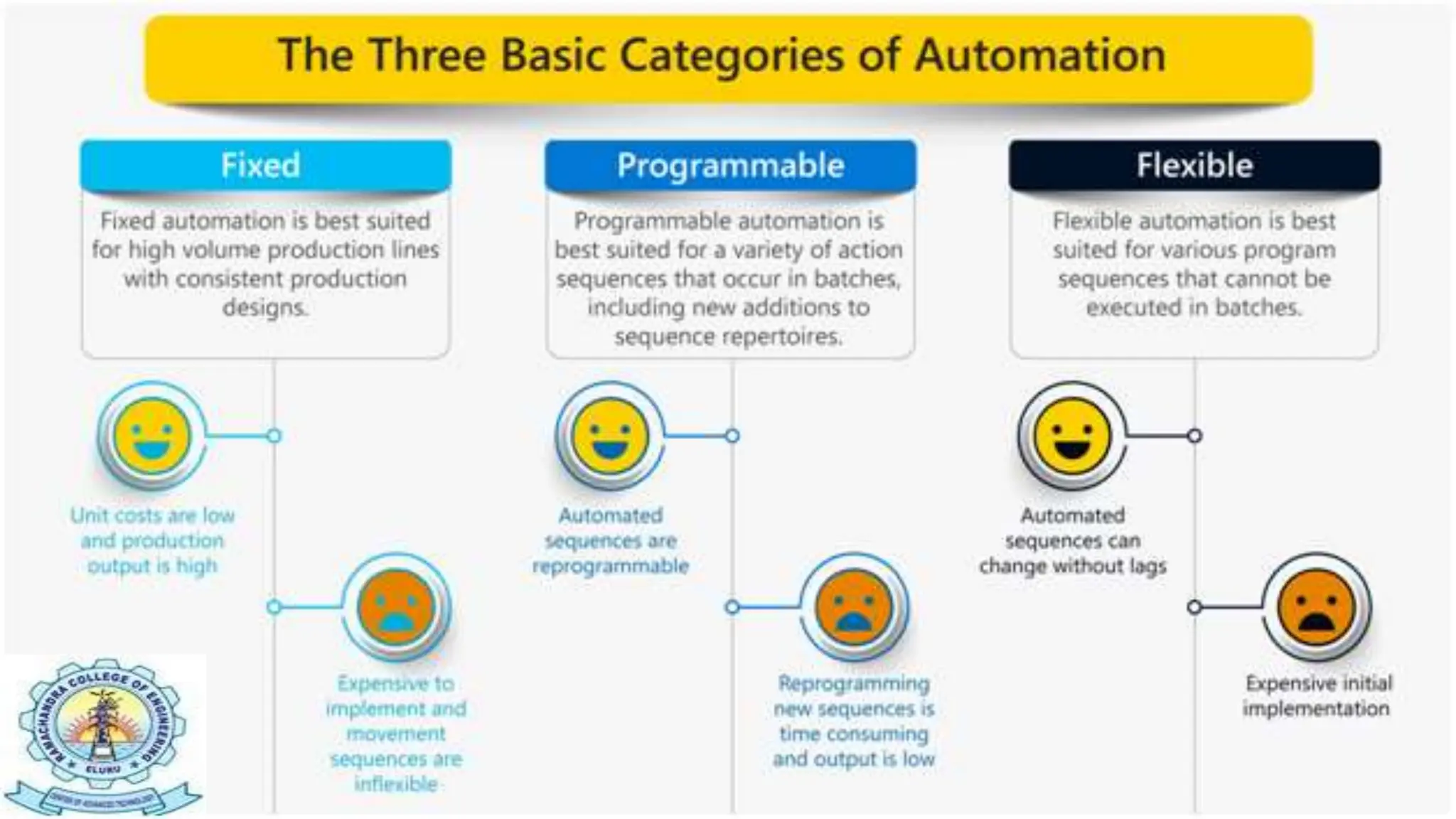

The document provides an overview of industrial robotics, defining robots and their key components, types, and historical developments, including the first industrial robot, Unimate. It discusses automation technologies, laws of robotics, and reasons for automation, as well as classifications of robots and their present and future applications in various industries. The document emphasizes the growing significance of robotics in tasks ranging from manufacturing to hazardous environments, healthcare, and service industries.