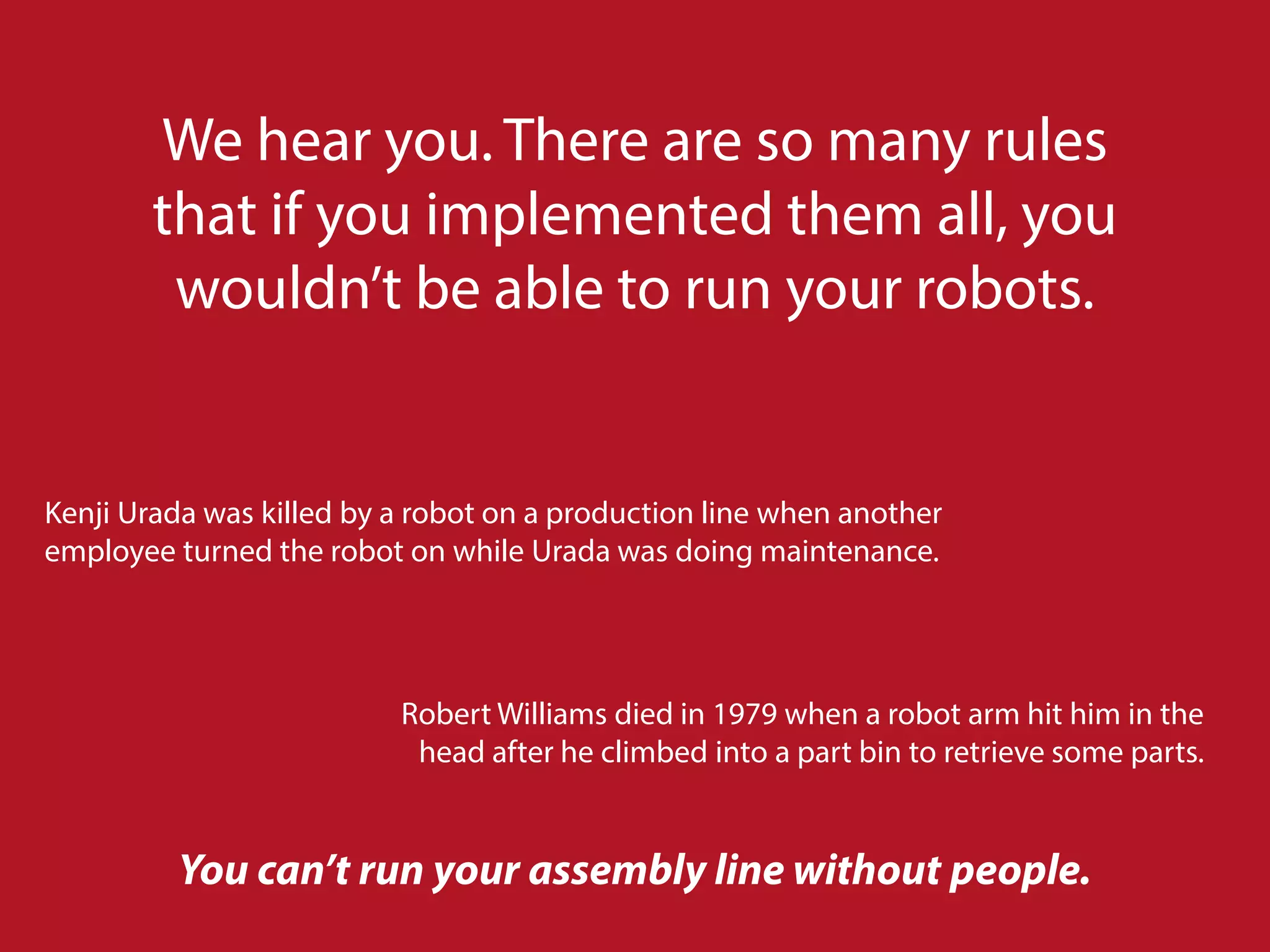

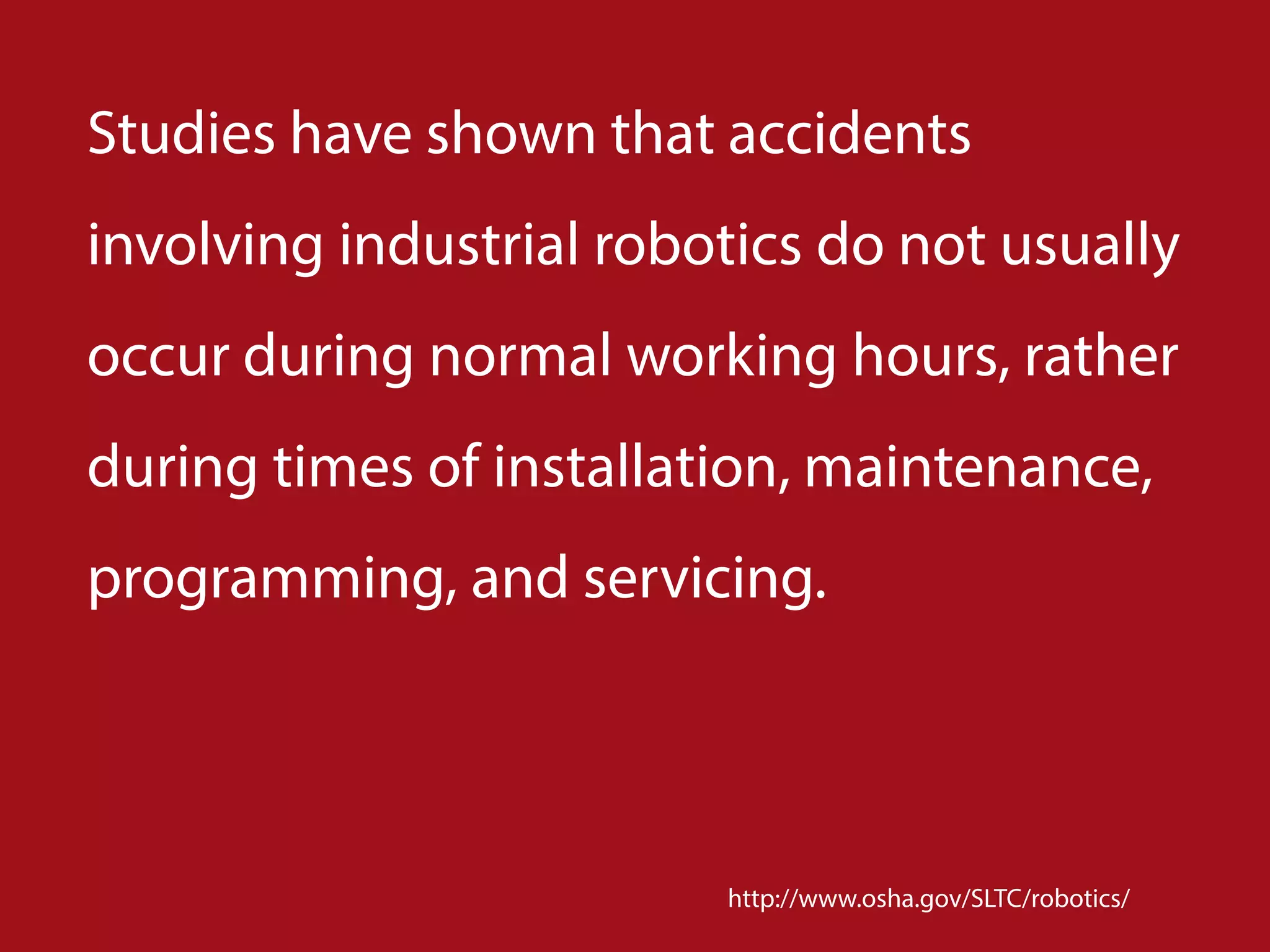

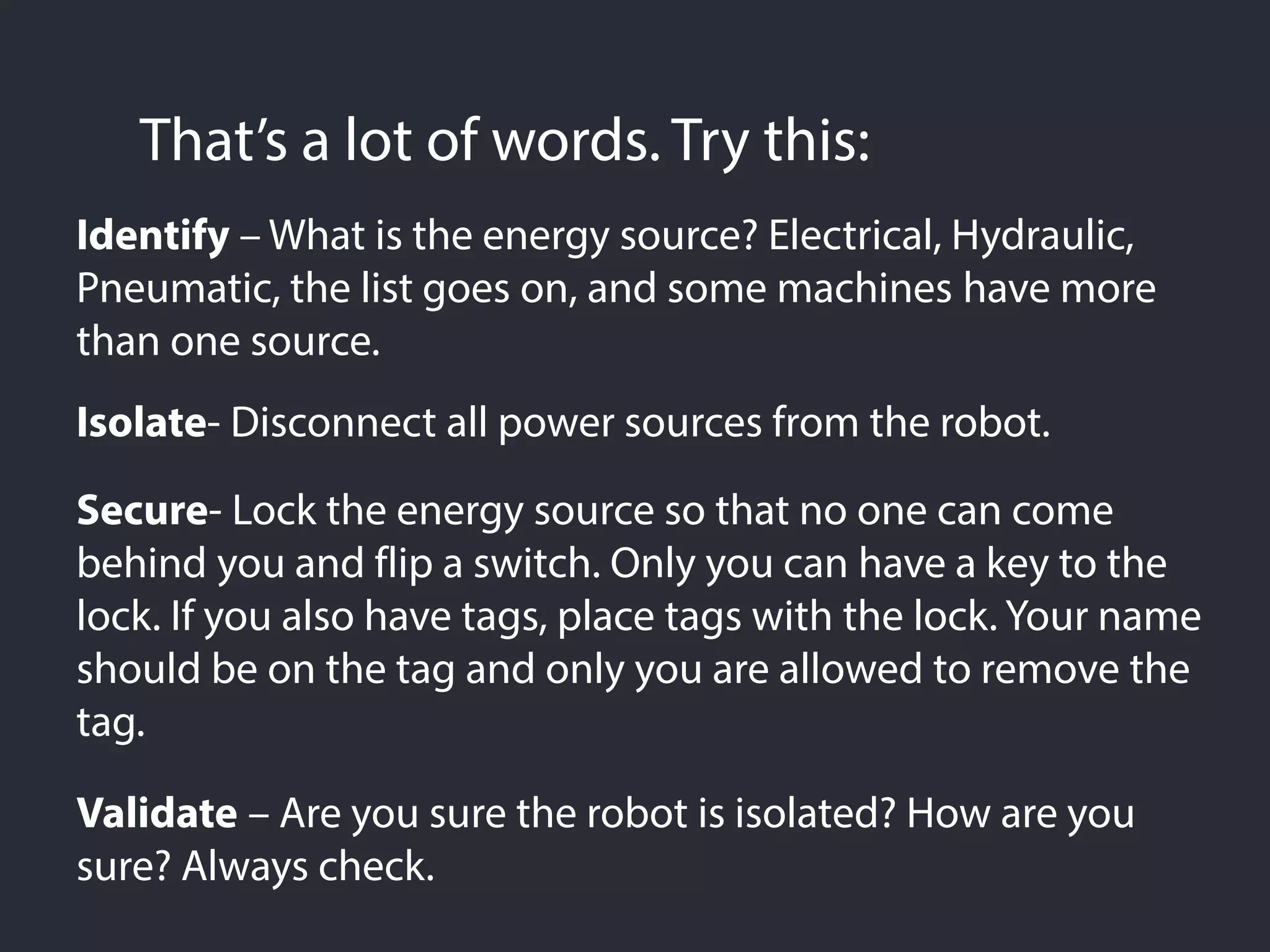

The document discusses essential robotic safety systems and the importance of lockout/tagout procedures to prevent accidents during maintenance and operation. It highlights the necessity for proper energy source management, interlocked doors, warning lights, cable management, and fume extraction systems to ensure worker safety. Additionally, it covers the use of software that enhances safety by defining safe operational zones for robots.