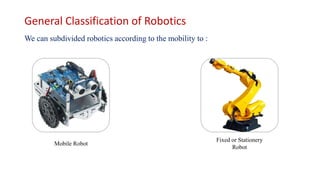

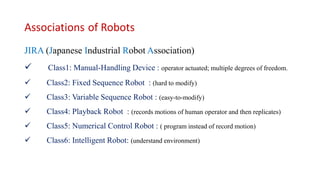

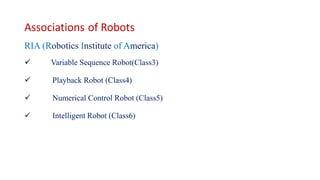

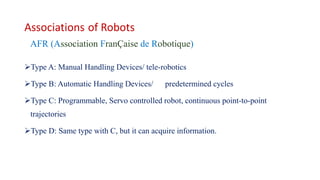

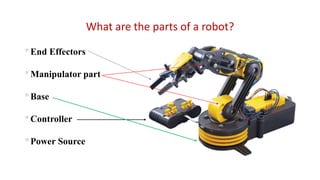

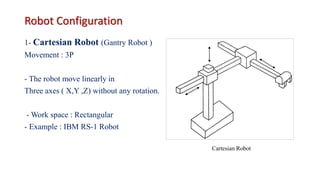

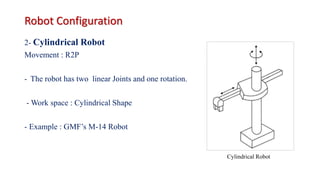

This document provides an overview of robotics. It defines a robot as a machine that can perform complex actions automatically without human interference, while robotics is the branch of technology dealing with the design, construction, and application of robots. The document classifies robots based on mobility and discusses common types of industrial robots. It also describes the parts of a robot, different robot configurations, specifications, common tasks performed by robots, and popular robotics shopping websites.