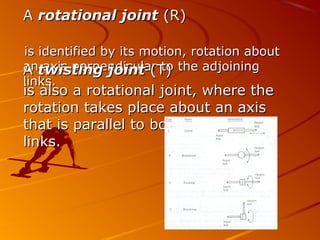

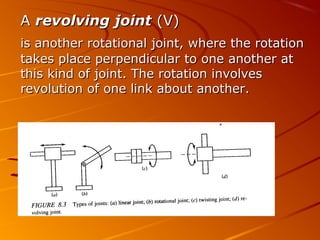

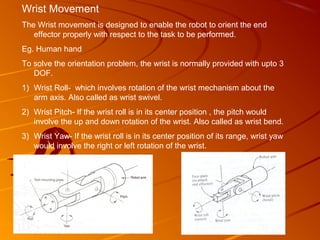

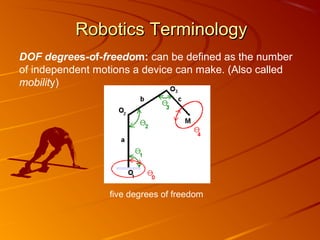

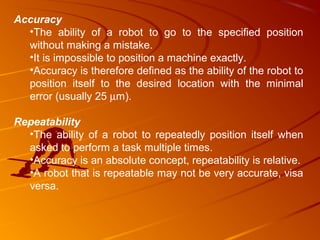

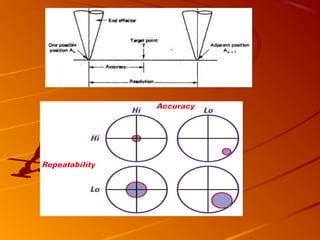

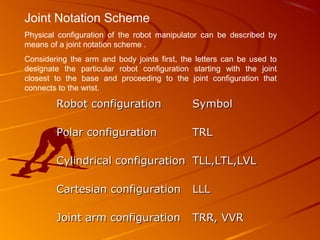

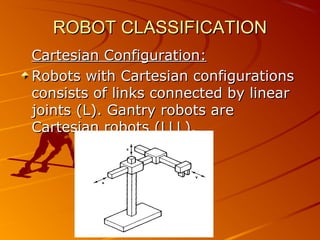

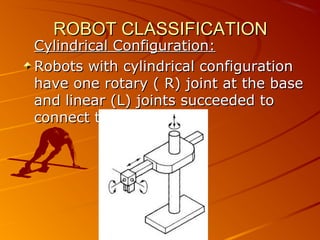

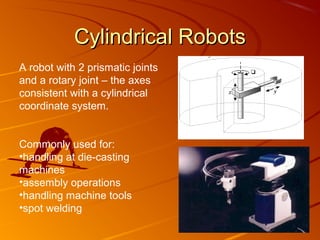

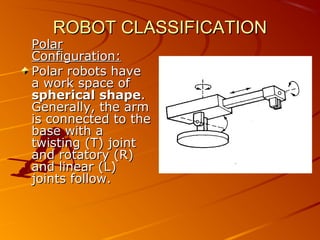

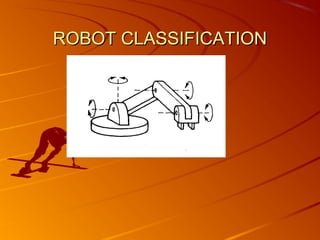

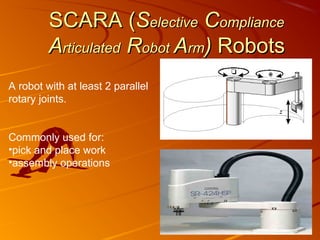

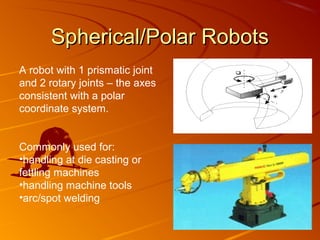

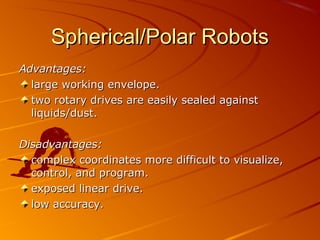

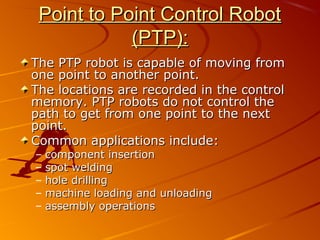

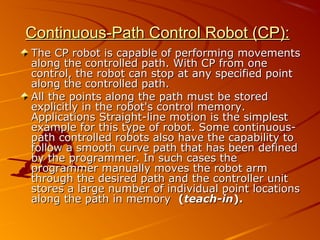

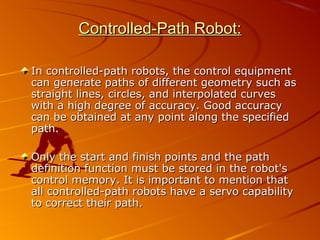

Industrial robots are programmable manipulators designed to move materials and tools. They consist of an arm, end effectors, drive mechanism, controller, and optional sensors. Robots have various types of joints that allow rotational, radial, and vertical movement. Common configurations include Cartesian, cylindrical, polar, and joint-arm designs. Robots are also classified based on their control system as either point-to-point or continuous-path robots.