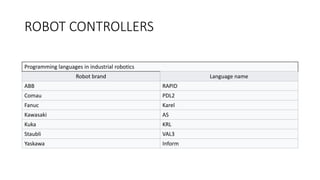

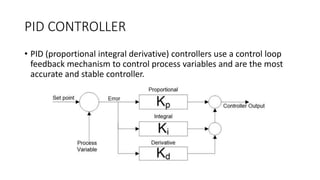

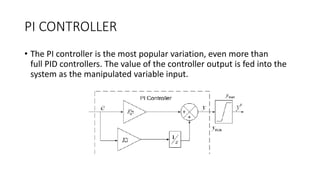

This document discusses robot controllers and motion control of robots. It describes how robot controllers are used to store information about the robot and environment and execute programs to operate the robot. It then discusses different types of motion control systems and control functions like velocity control and position control. It also describes PID and PI controllers that are commonly used for feedback control. Finally, it outlines different types of robot control including point-to-point, continuous path, and controlled path robots.