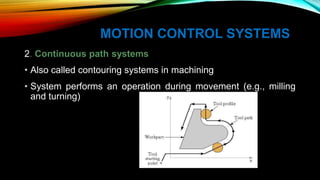

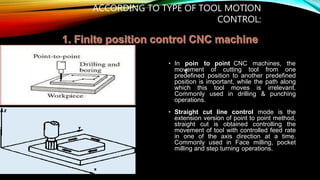

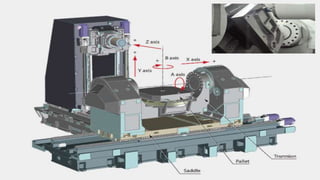

The document details the concepts of numerical control (NC), computer numerical control (CNC), and distributed numerical control (DNC) machine tools, outlining their components, advantages, limitations, and classifications. It also describes automated transfer lines, their configurations, types of transfers, transport mechanisms, and control functions necessary for efficient operations. Overall, it emphasizes the technological advancements in machine tools that enhance productivity, accuracy, and operational efficiency.