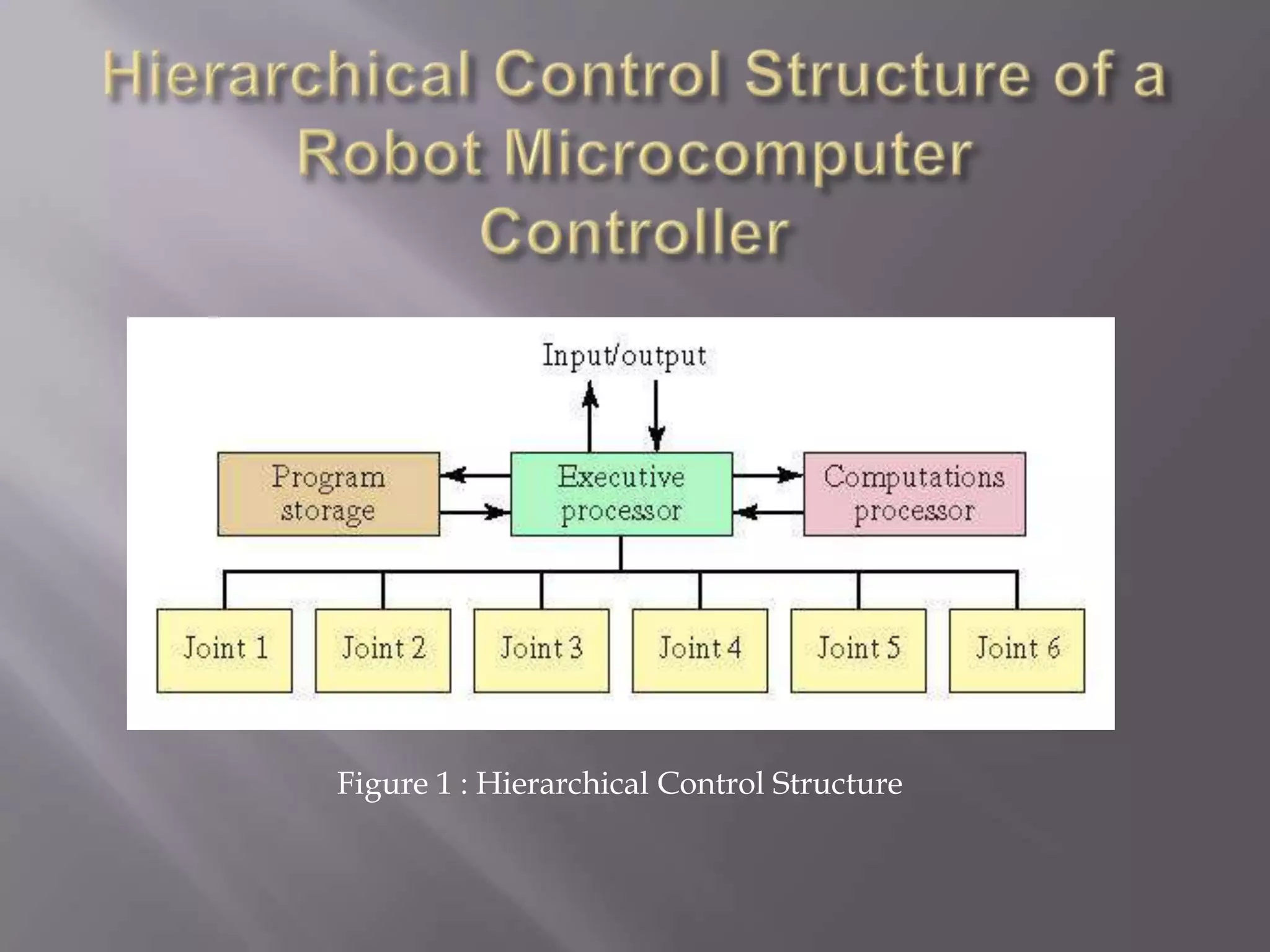

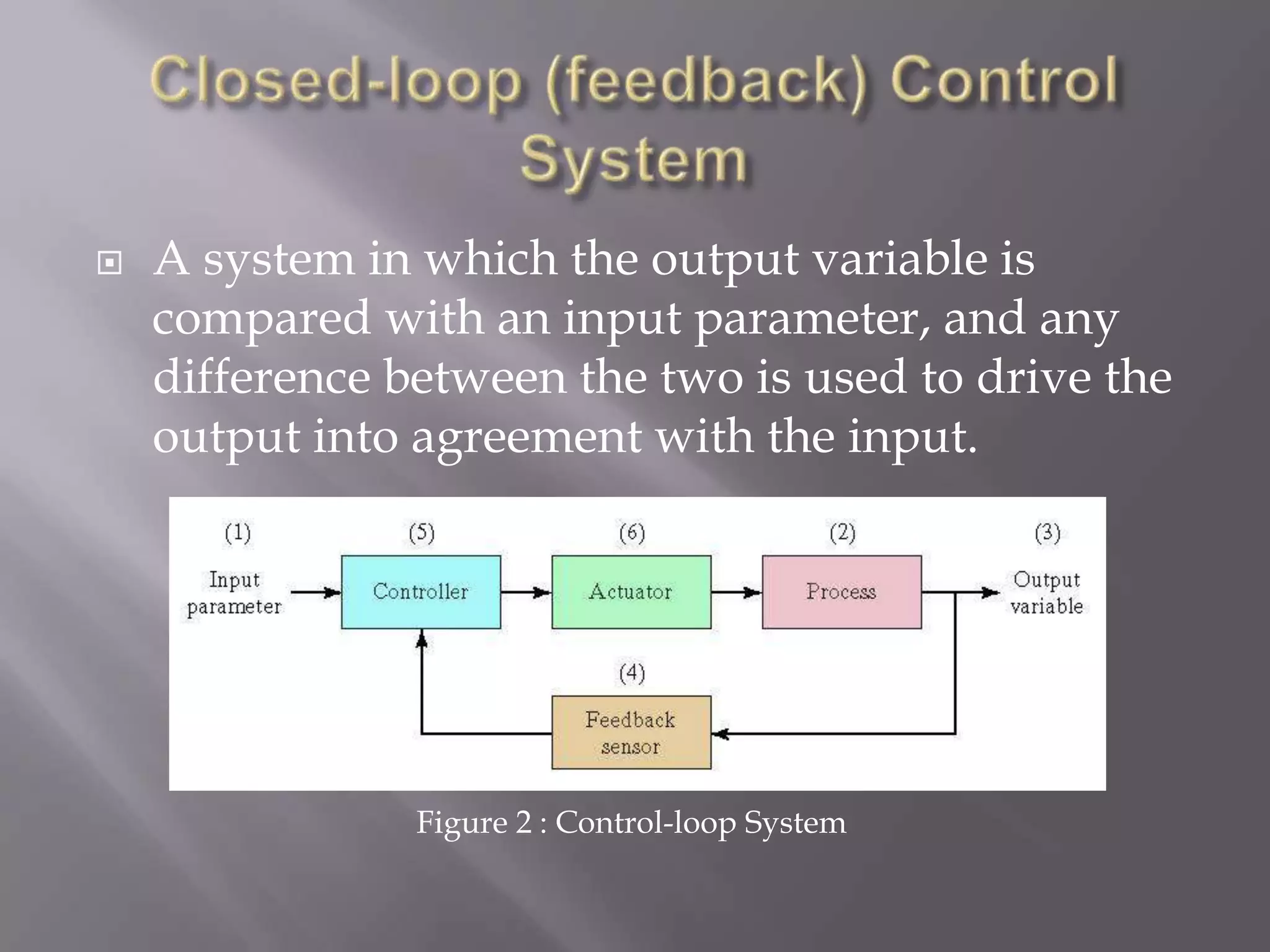

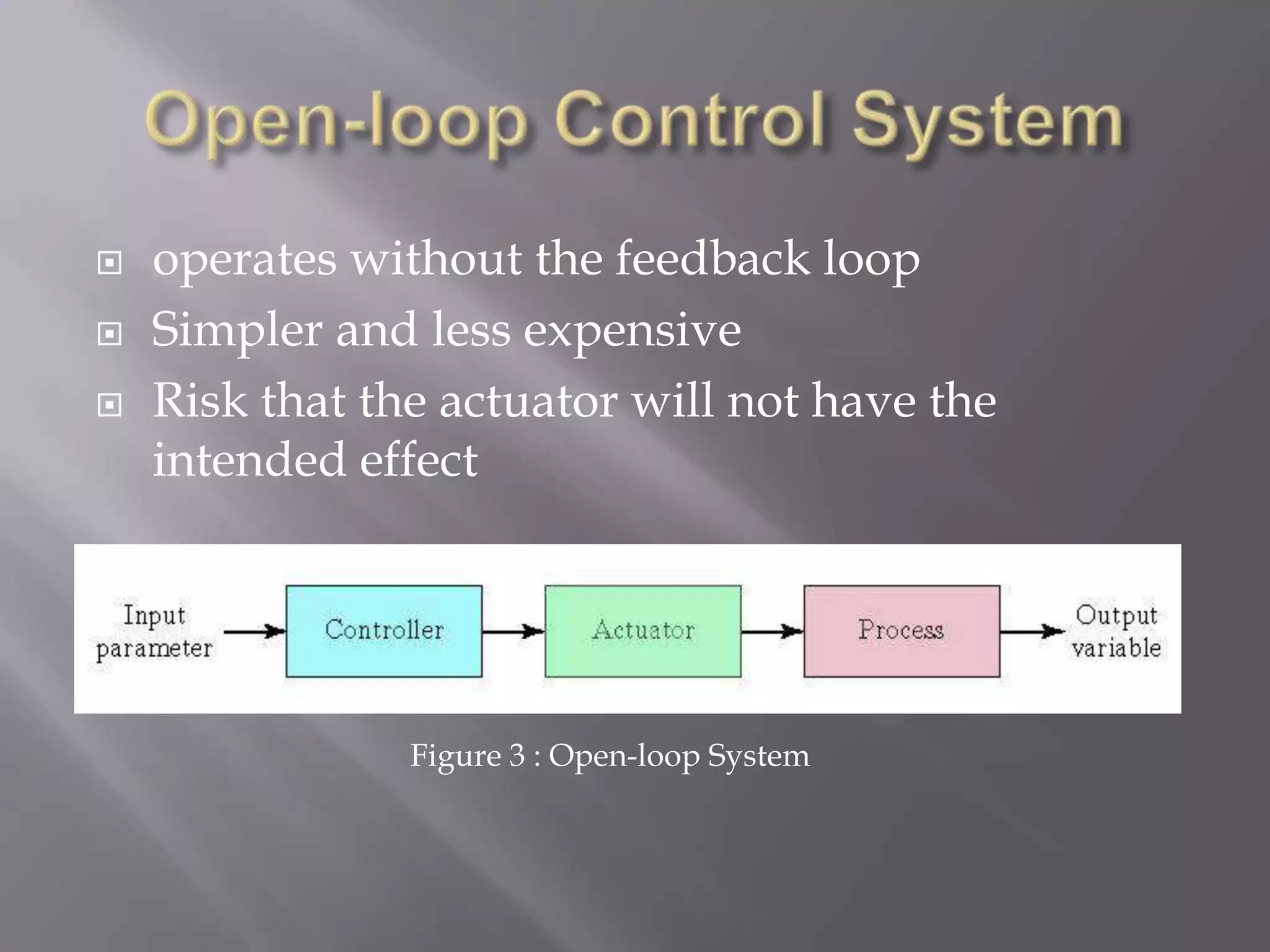

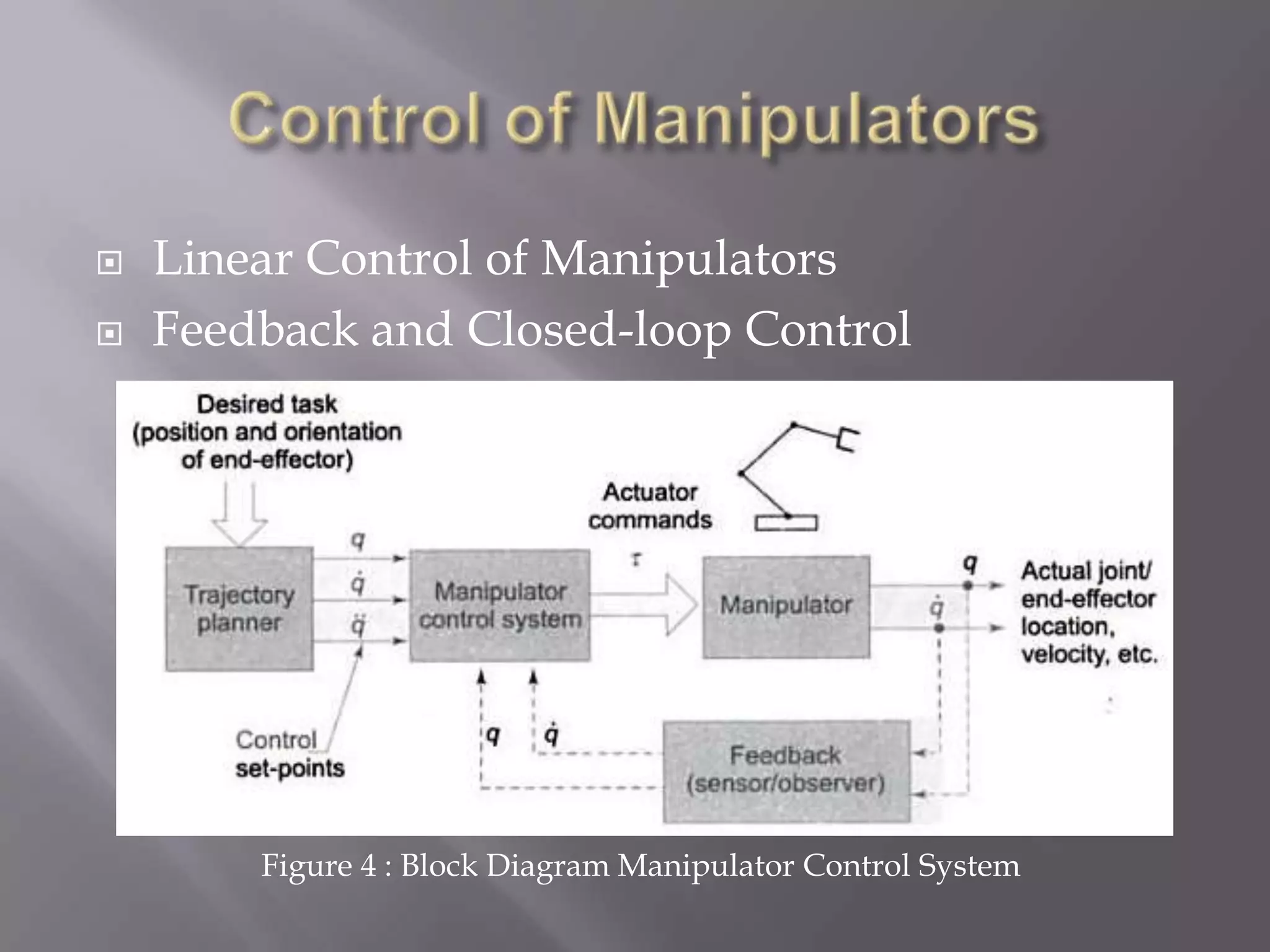

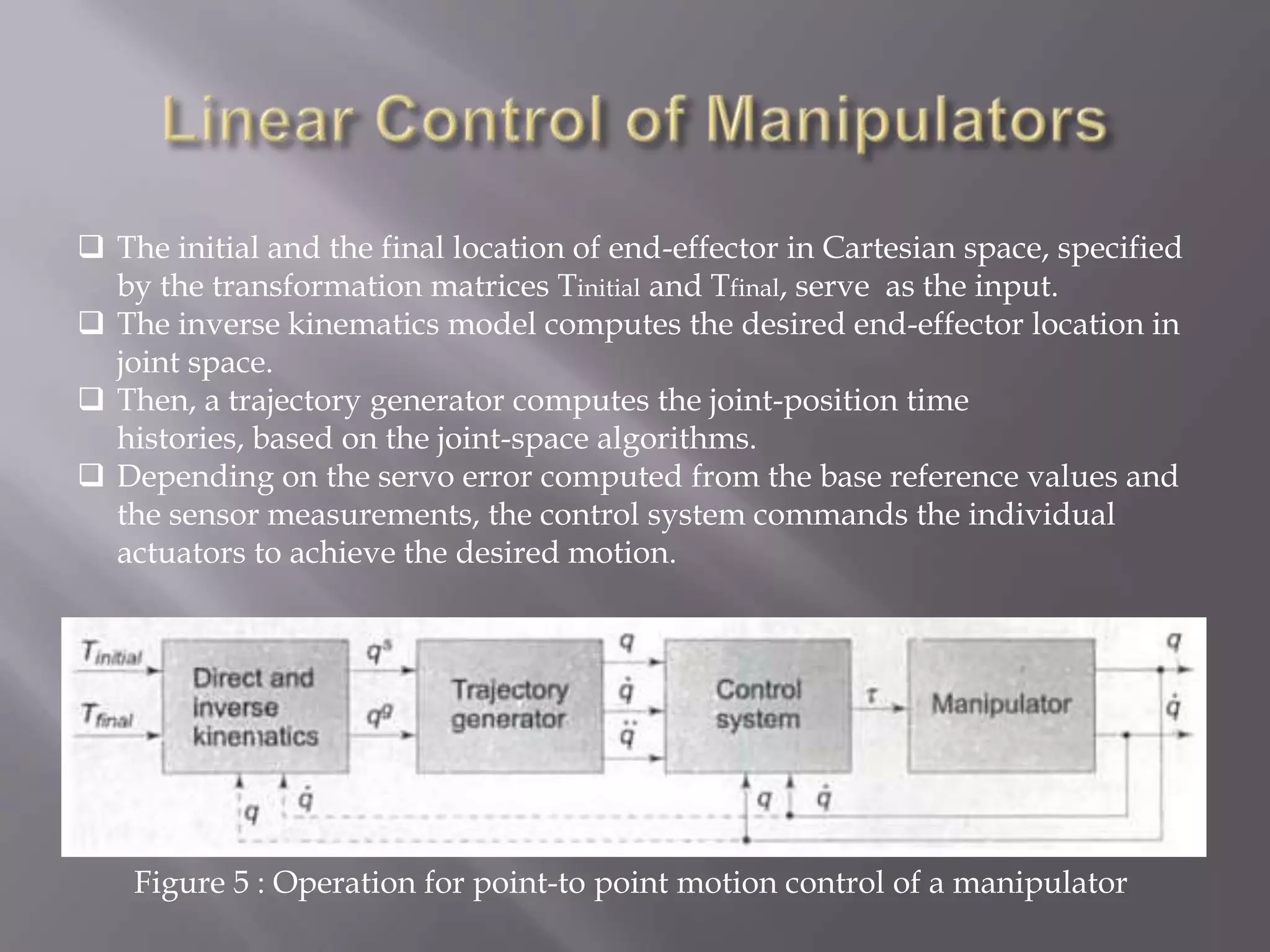

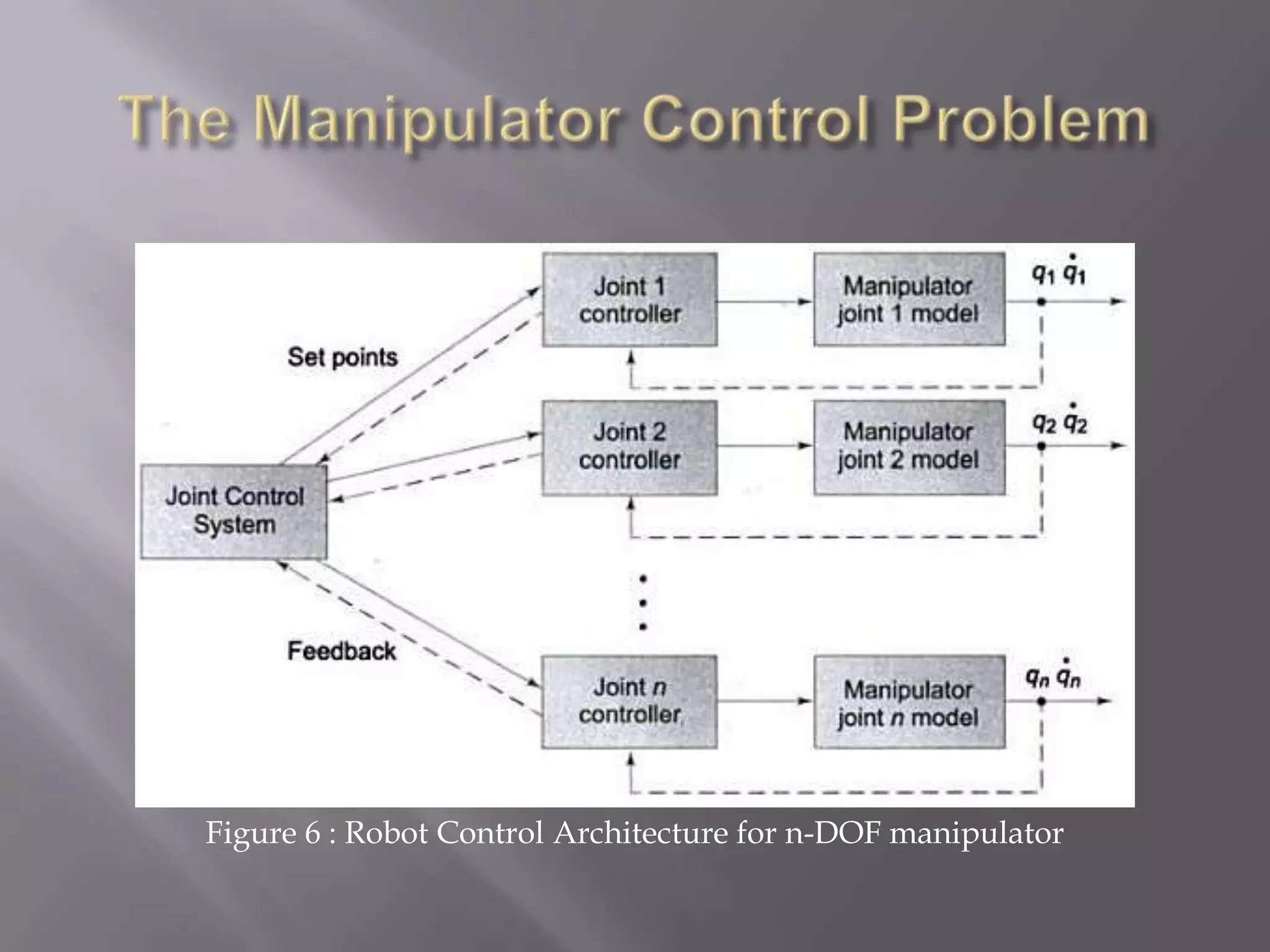

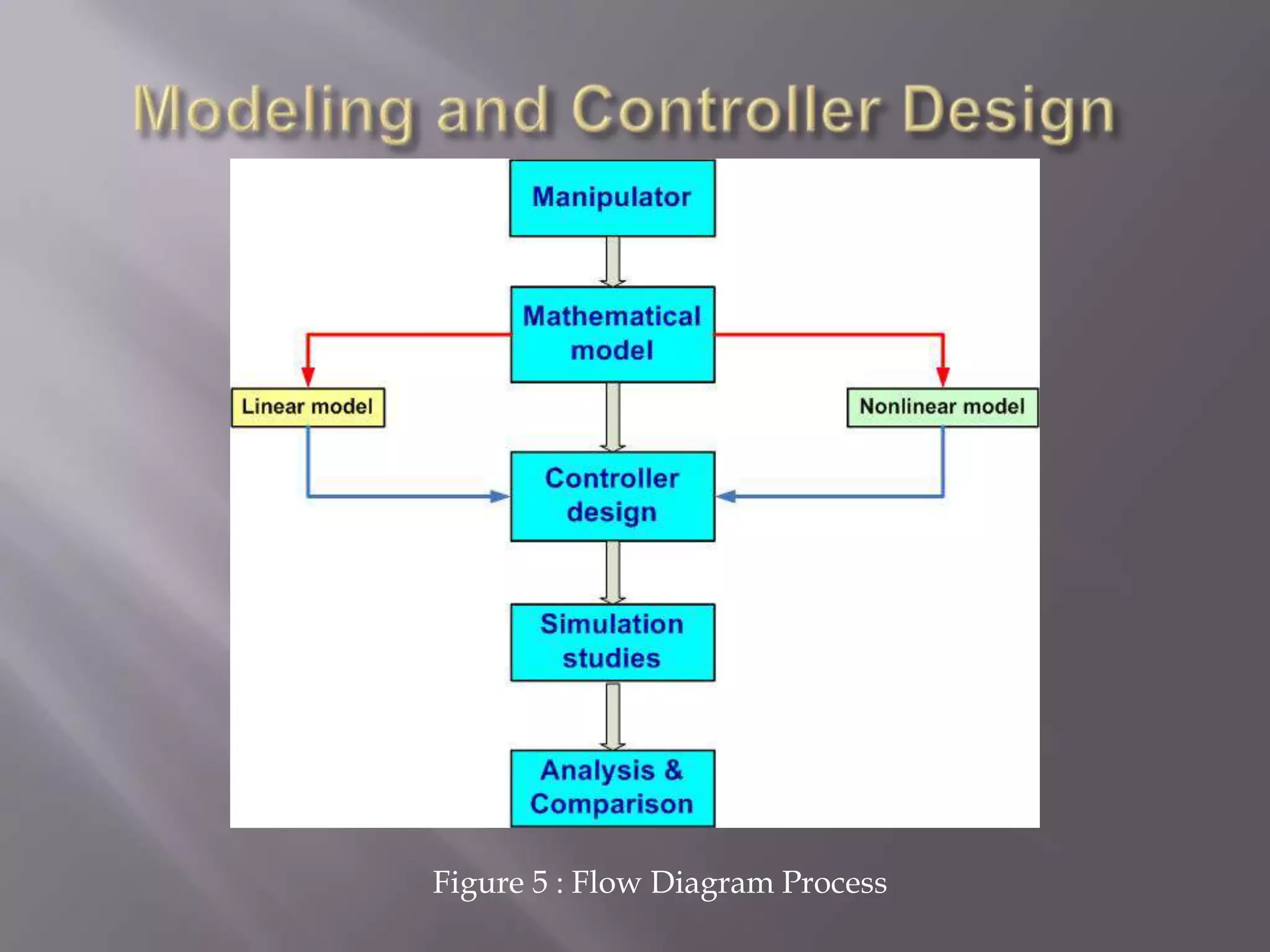

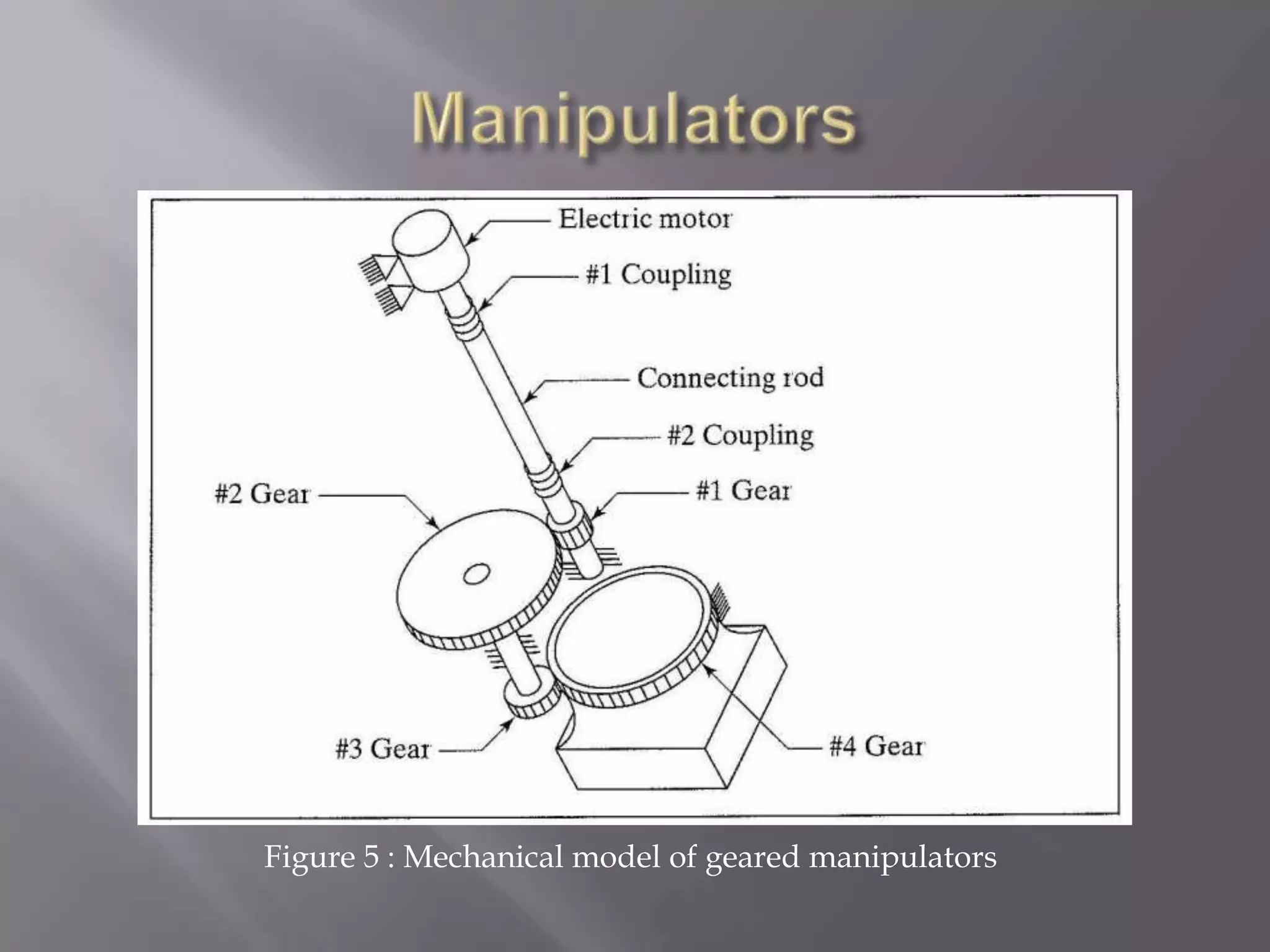

The document discusses control systems for robot manipulators. It covers open-loop and closed-loop control systems, with closed-loop being preferred using feedback. It describes using linear control techniques to approximate manipulator dynamics and designing controllers to meet stability and performance specifications. Common control techniques for manipulators are also summarized like PD, PID, state space control and adaptive/intelligent methods.