Embed presentation

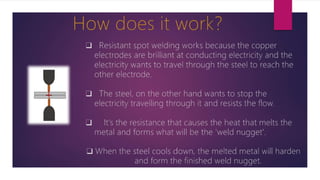

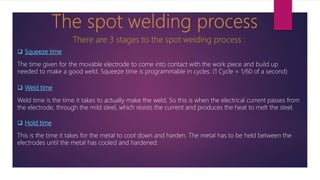

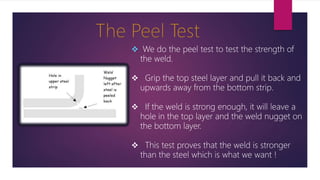

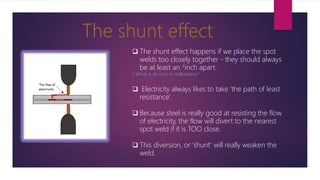

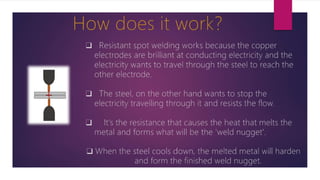

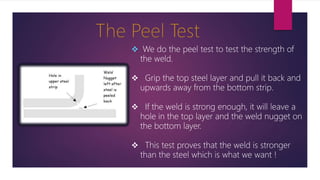

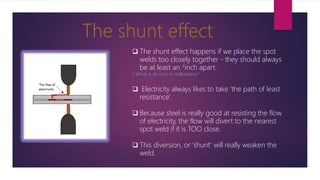

The document discusses resistance spot welding, which involves cleaning surfaces, applying a weld-through primer, and ensuring overlapping surfaces. It describes squeeze time as the time for the electrode to contact the work piece, weld time as when current passes and welding occurs, and hold time for the metal to cool. A peel test is used to check weld strength by pulling layers apart and verifying a hole is left in one layer. The document warns that spot welds placed too closely together can experience a shunt effect where electricity takes the path of least resistance between welds, weakening them.