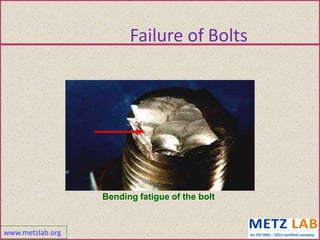

The document provides an in-depth overview of failure analysis covering principles, types of failures, failure modes, methods for conducting analyses, and prevention strategies. It emphasizes the importance of proper observation and data collection, identifies various failure mechanisms, and outlines the role of material analysis techniques. Additionally, it discusses the qualifications of an analyst and includes practical examples of failures in engineering contexts.