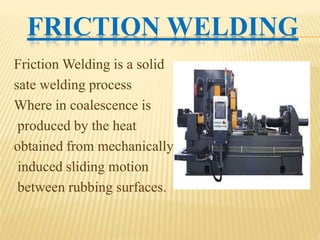

The document discusses friction stir welding (FSW), a modern solid-state joining process that utilizes frictional heat generated by a rotating tool to join materials without melting. It outlines various welding types, advantages such as low distortion and energy efficiency, and disadvantages including rigid clamping requirements and high initial costs. Applications include shipbuilding, aerospace, and railway industries, while also noting limitations such as keyholes at weld ends.