Embed presentation

Downloaded 719 times

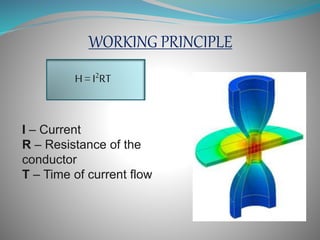

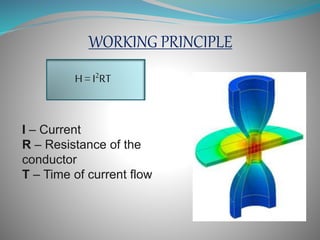

Spot welding is a metal joining process where two metal surfaces are welded together by resistance heating when a large current is passed through them. The current causes the metal to heat up and melt together. It allows for quick and easy welding of multiple metal sheets simultaneously without filler metals or flames. However, spot welds have lower strength than other weld types and repairs can be difficult. It is commonly used in the automobile industry to join metal car body panels and parts.