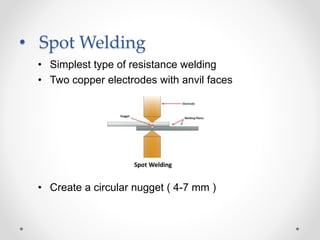

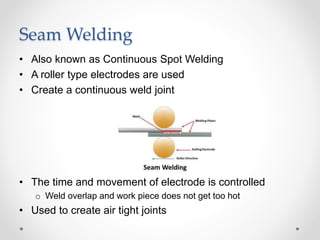

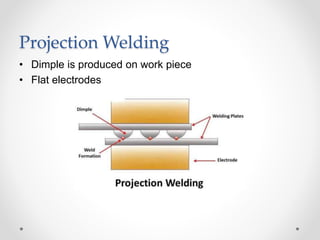

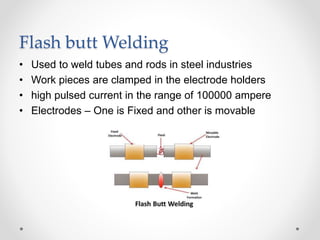

Resistance welding is a thermo-electric process that generates heat through electric resistance, allowing for various types including spot, seam, projection, and flash butt welding. It is widely used in industries such as automotive and production of fasteners due to its high speed, automation capabilities, and ability to weld both similar and dissimilar metals. However, it has disadvantages such as high equipment costs and limitations in work piece thickness and joint strength.