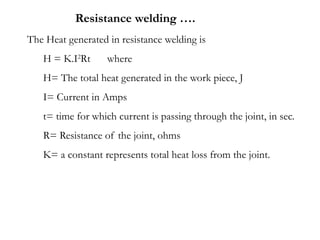

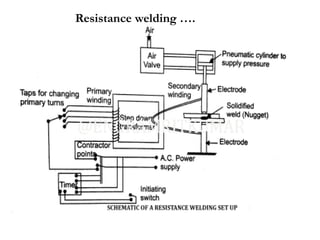

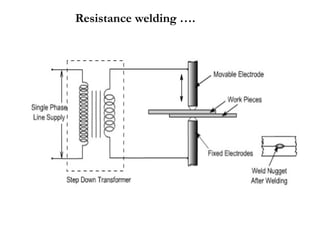

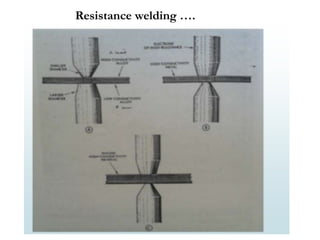

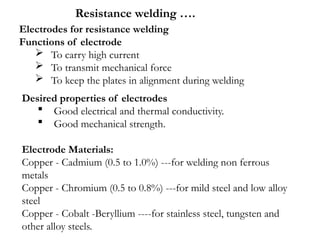

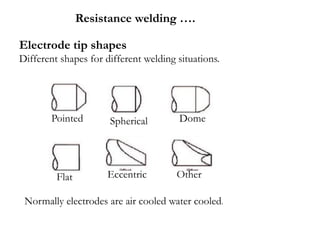

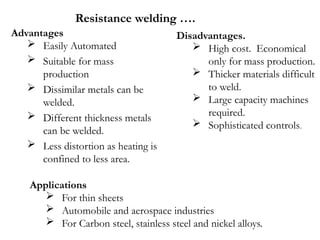

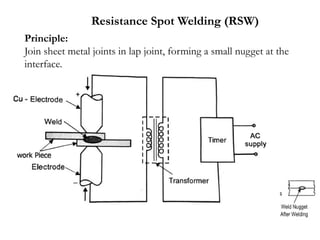

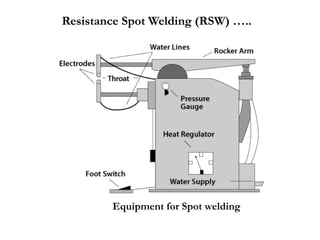

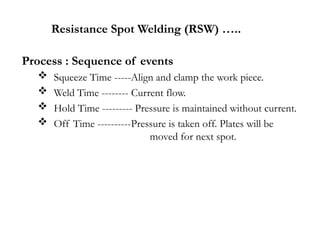

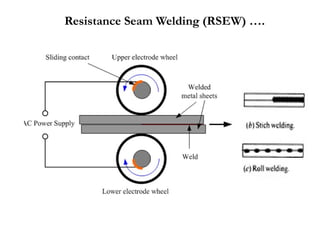

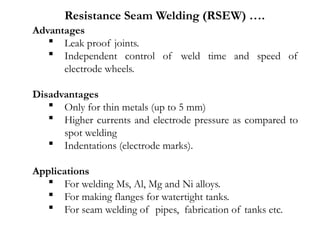

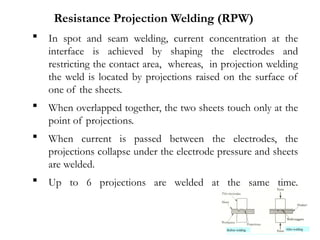

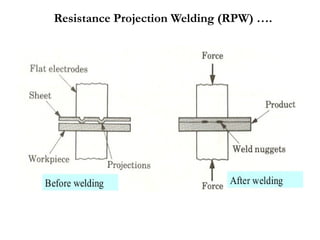

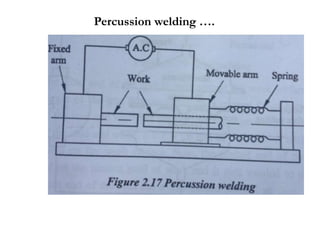

The document details various welding processes, primarily focusing on resistance welding techniques such as spot, seam, and projection welding. It outlines the principles, advantages, disadvantages, applications, and essential equipment for each process, emphasizing parameters like current, time, and pressure. Additionally, it discusses electrode materials and their characteristics, contributing to the effectiveness of the welding methods described.