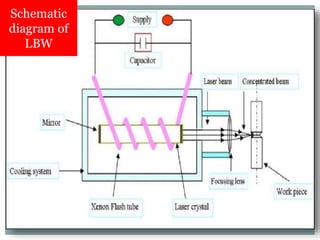

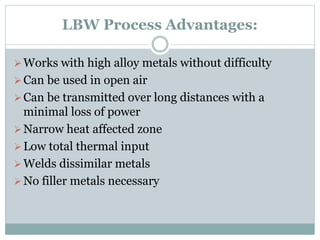

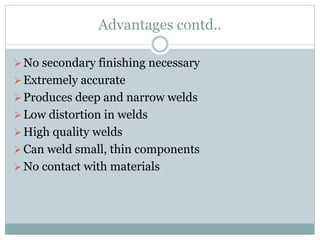

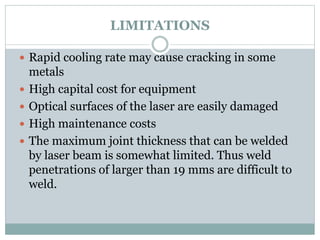

This presentation discusses laser beam welding (LBW), including what a laser beam is, its properties, types of lasers, the LBW process, principles of operation, mechanics, parameters, advantages, and limitations. A laser beam is a powerful, narrow, monochromatic beam created when atoms in a lasing medium are excited by a flash tube, emitting photons. LBW uses the concentrated heat from a laser beam to fuse metals together without filler material. It offers advantages like narrow welds, low distortion, and the ability to weld dissimilar and high-alloy metals. However, it also has high costs and limitations such as difficulty welding thick joints.