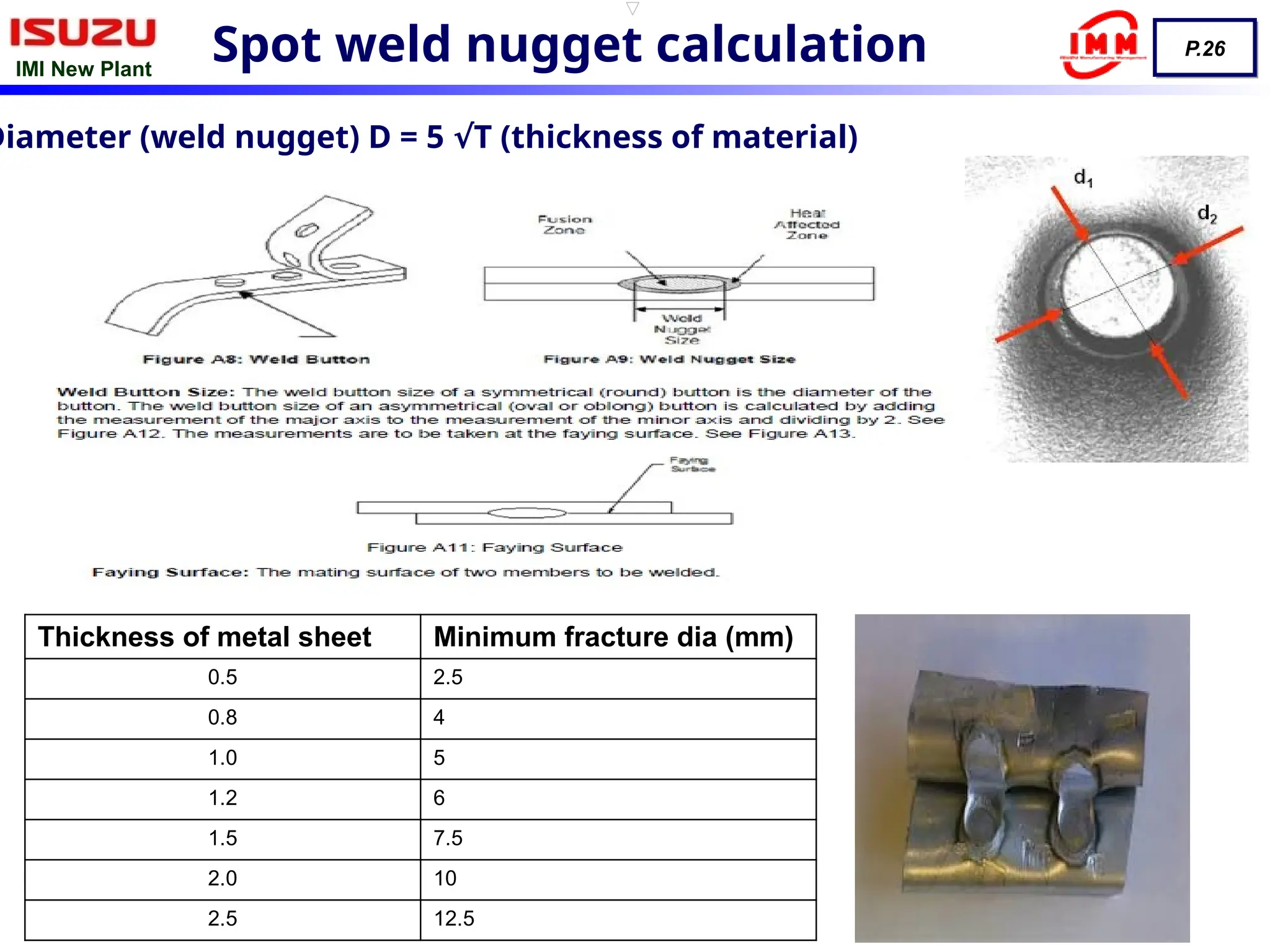

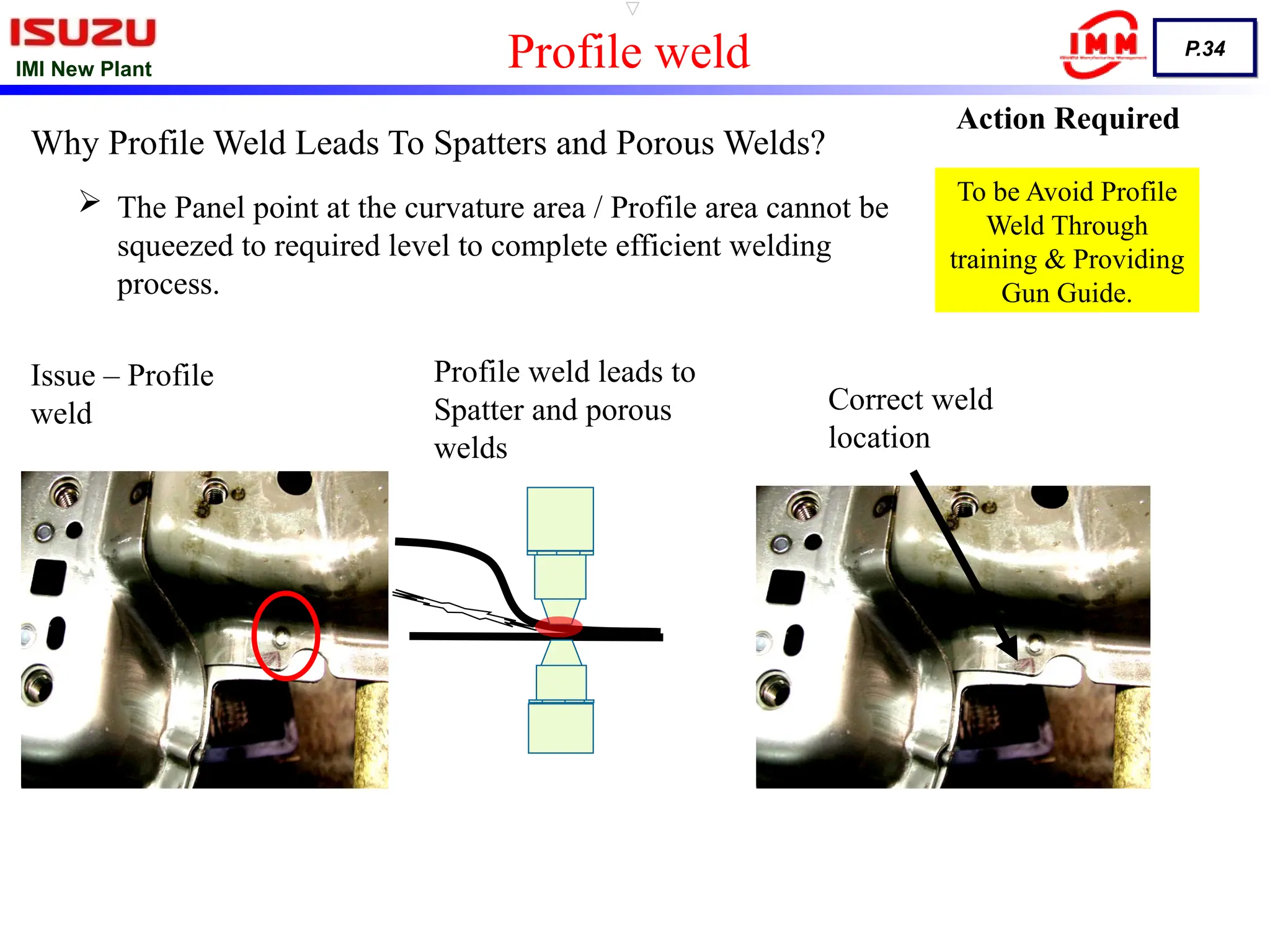

The document provides a comprehensive overview of various welding processes, focusing primarily on spot welding. It details the technical aspects, such as the steps involved in the spot welding cycle, the factors influencing weld quality, and the historical development of welding techniques. Additionally, the document outlines applications, advantages, defects, and quality control measures associated with spot welding.