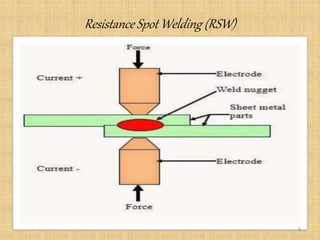

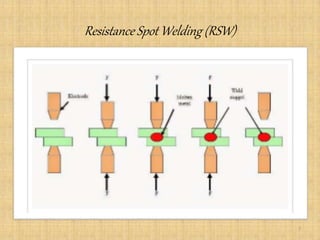

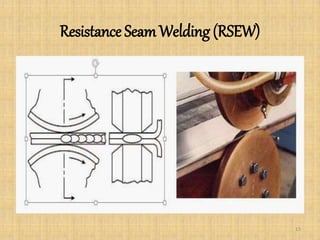

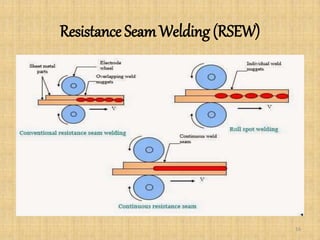

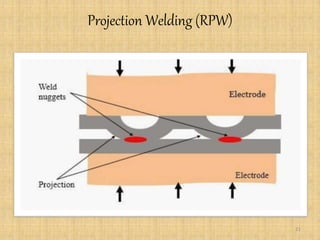

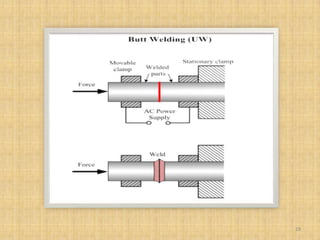

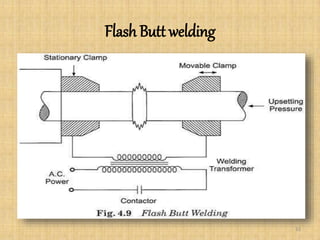

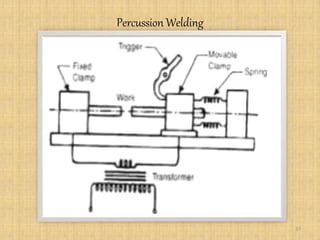

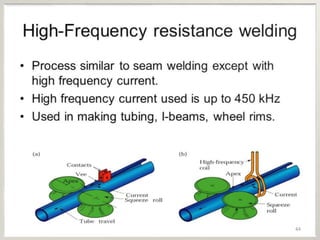

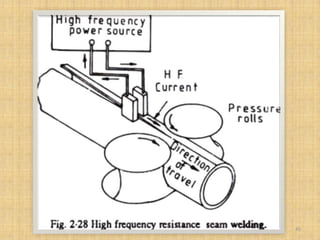

The document provides an extensive overview of various resistance welding processes including resistance spot welding, seam welding, projection welding, and butt welding, detailing their principles, advantages, disadvantages, and applications. It highlights how these processes utilize the heat generated from electrical resistance and applied pressure to coalesce materials without the need for filler metals. Additionally, it discusses specific methods like flash butt and percussion welding, along with the impact of high-frequency resistance welding in manufacturing applications.