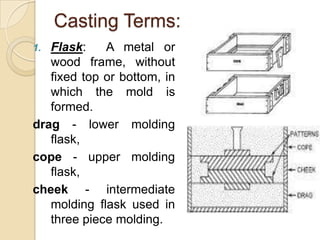

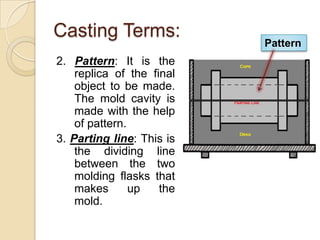

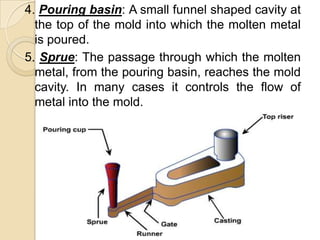

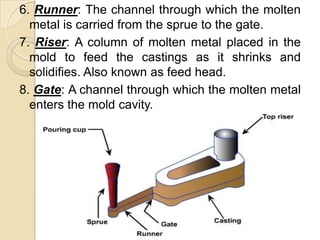

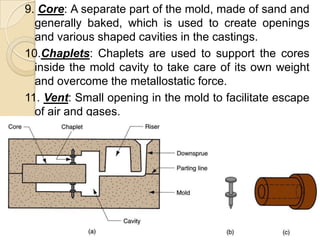

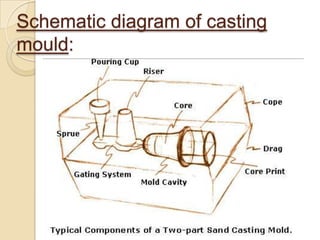

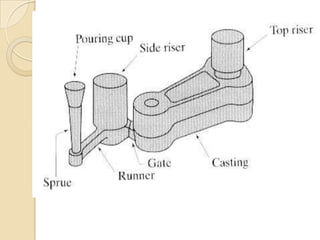

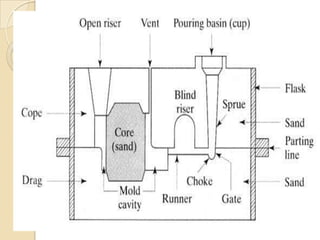

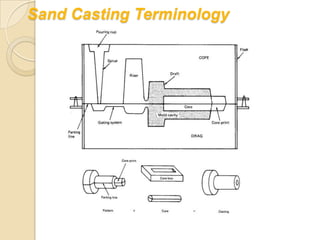

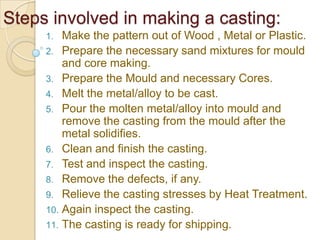

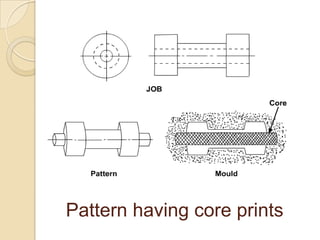

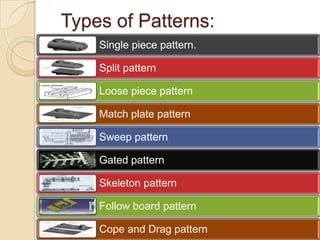

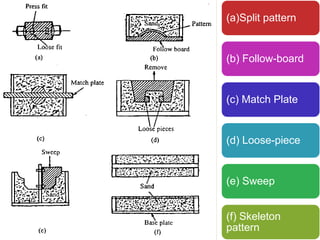

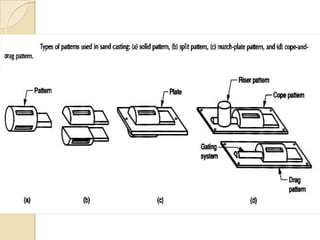

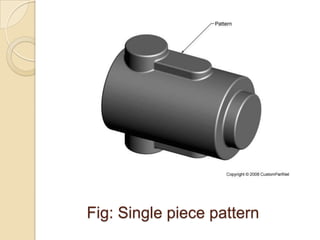

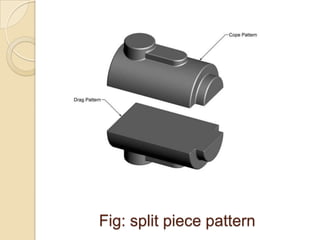

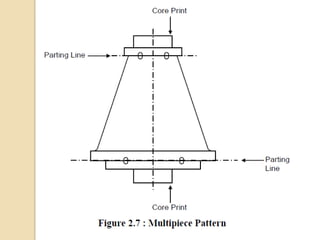

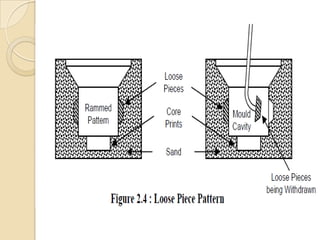

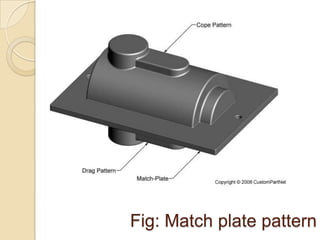

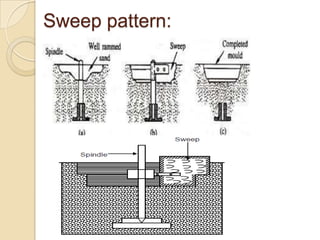

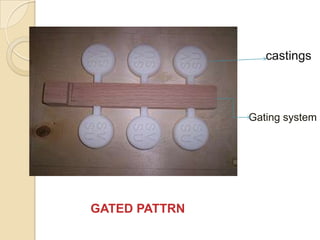

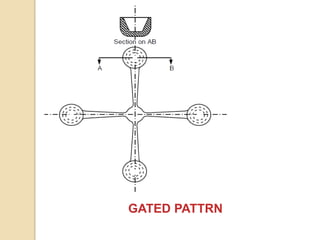

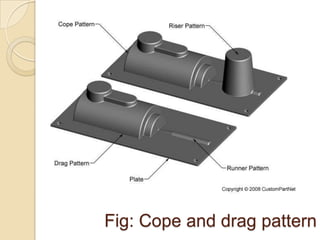

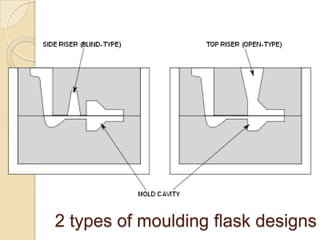

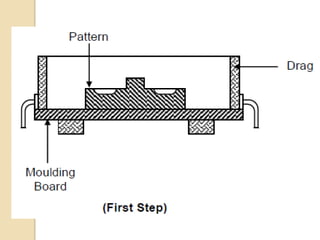

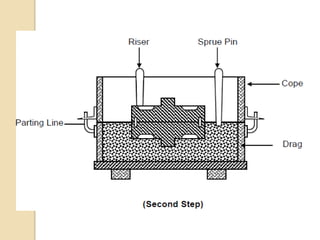

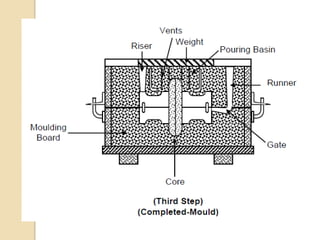

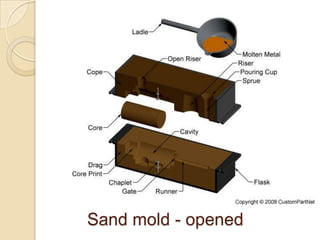

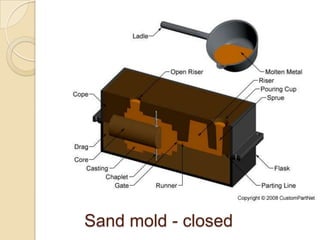

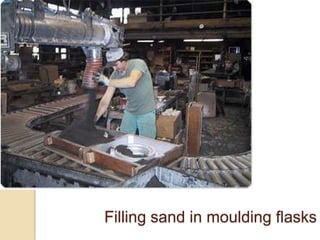

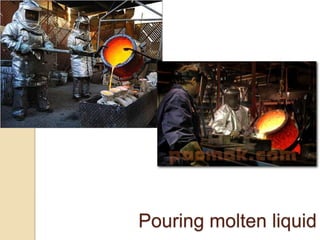

The document discusses the process of sand casting. It begins by defining foundry and casting as the process of producing metal parts by pouring molten metal into a prepared mold. It then provides terminology used in casting such as flask, pattern, parting line, pouring basin, sprue, runner, riser, gate, core, and chaplets. The steps of sand casting are outlined as making the pattern, preparing sand mixtures, making the mold and cores, melting metal, pouring, cleaning, inspecting, and heat treating. Common casting materials and applications are also listed.