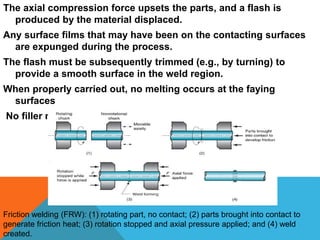

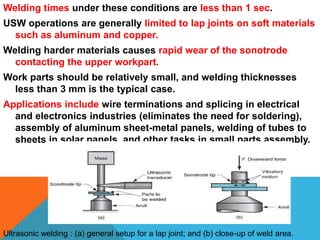

(1) Friction welding and ultrasonic welding are solid-state welding processes that do not involve melting. Friction welding uses rotation or linear motion to generate heat through friction and create a weld. Ultrasonic welding uses high-frequency vibrations to break down surface films and form bonds.

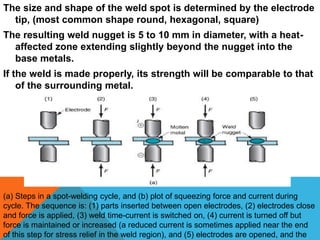

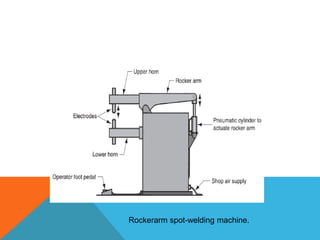

(2) Resistance welding is a fusion process that uses electrical current to generate heat and melt the faying surfaces. Resistance spot welding is widely used in automotive and appliance manufacturing to join sheet metal parts with thousands of spot welds.

(3) Proper parameters of current, time, and pressure are needed to create strong welds without defects in both solid-state and fusion welding processes. Process