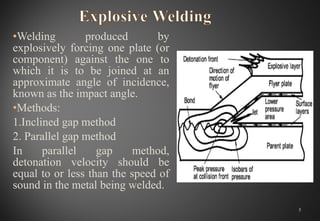

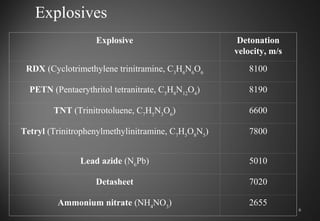

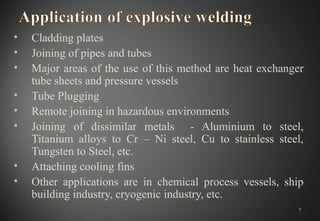

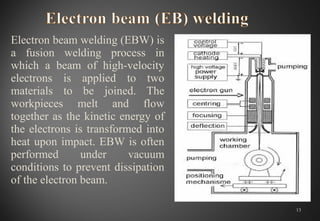

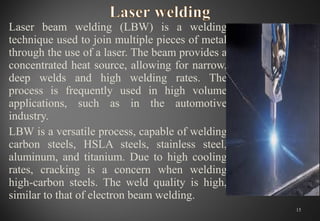

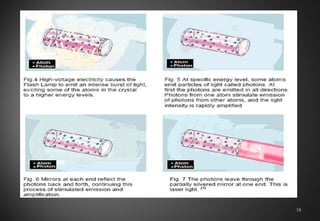

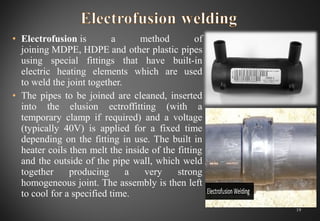

The document discusses several welding techniques including explosive welding, ultrasonic welding, electron beam welding, laser beam welding, electrofusion, and plasma arc welding. Explosive welding uses detonation to join metals by forcing them together at high speed. Ultrasonic welding uses high frequency vibrations to create solid-state welds without other joining methods. Electron beam and laser beam welding use focused beams of electrons or laser light to melt materials together. Electrofusion uses electric heating elements in plastic pipe fittings to melt and fuse pipes. Plasma arc welding uses an ionized gas to generate an arc between an electrode and workpiece to produce welding heat.