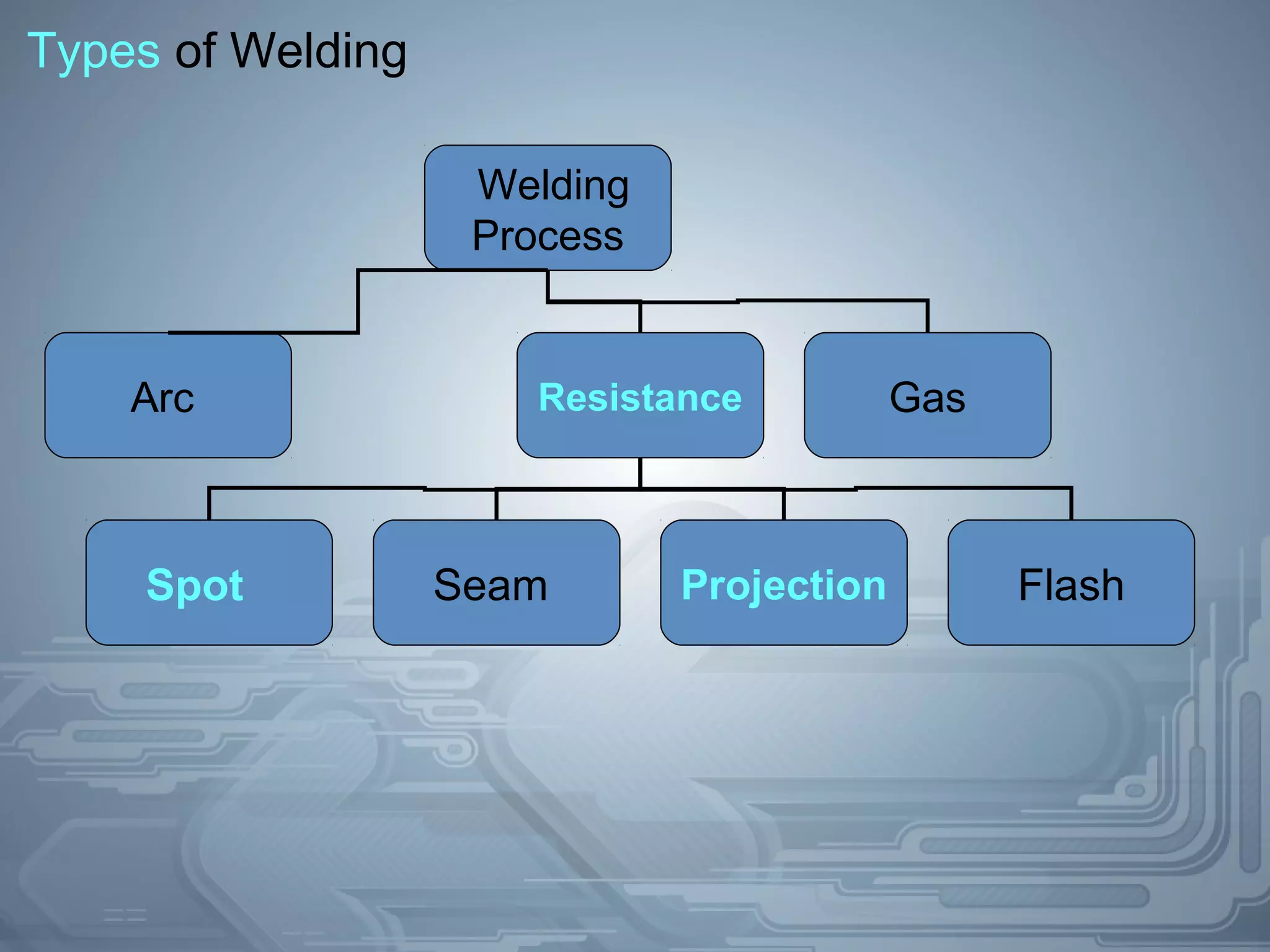

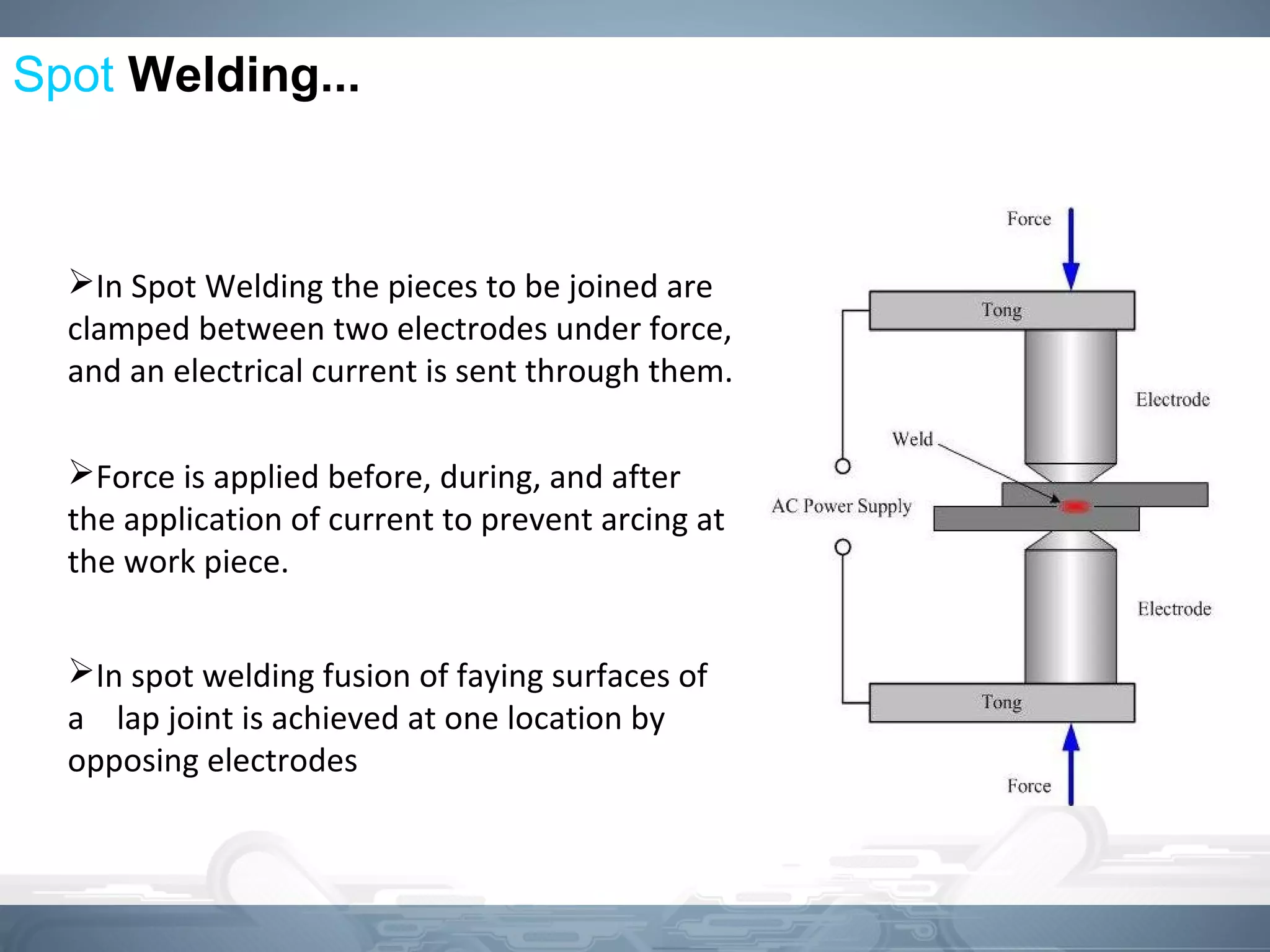

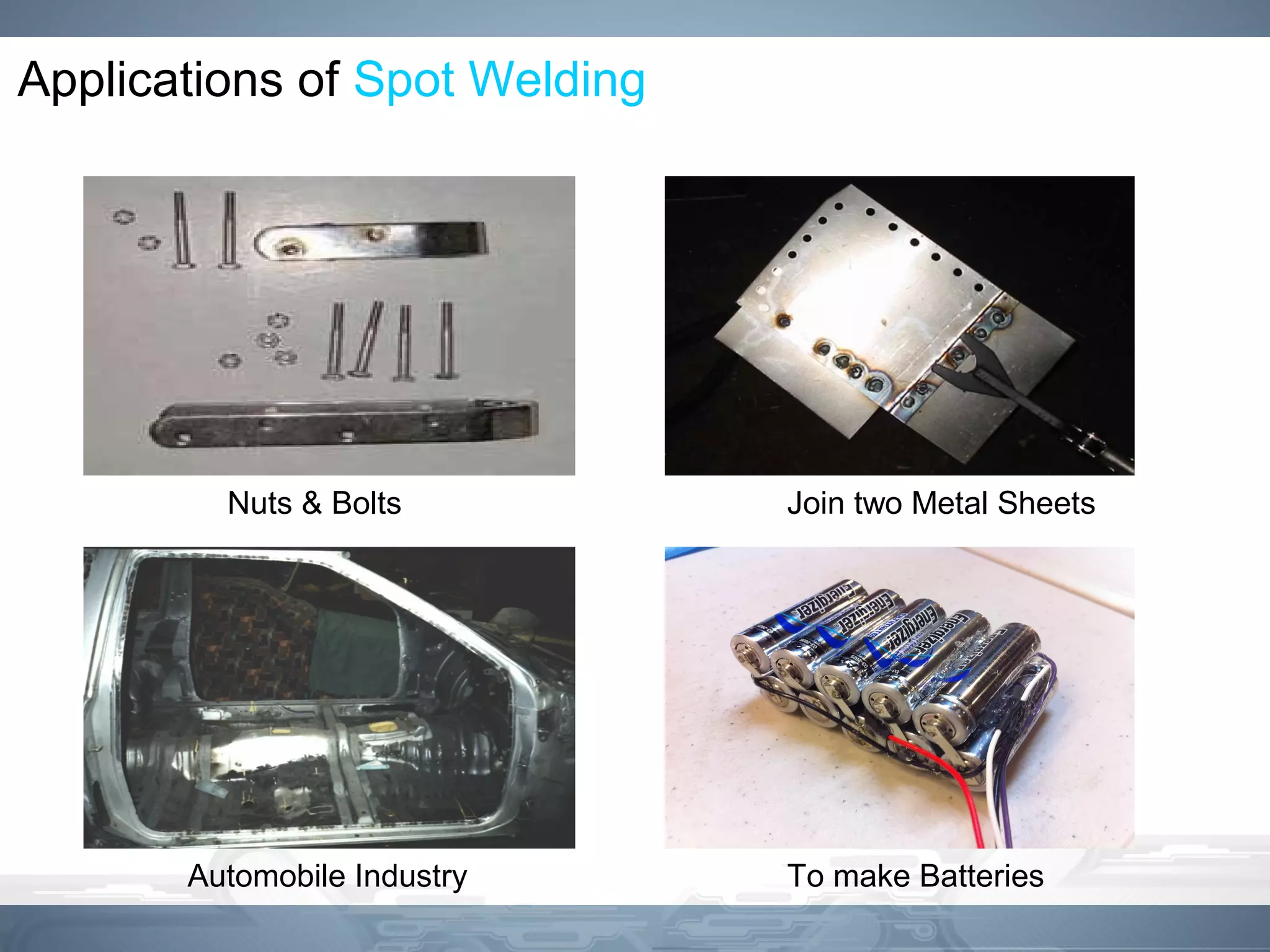

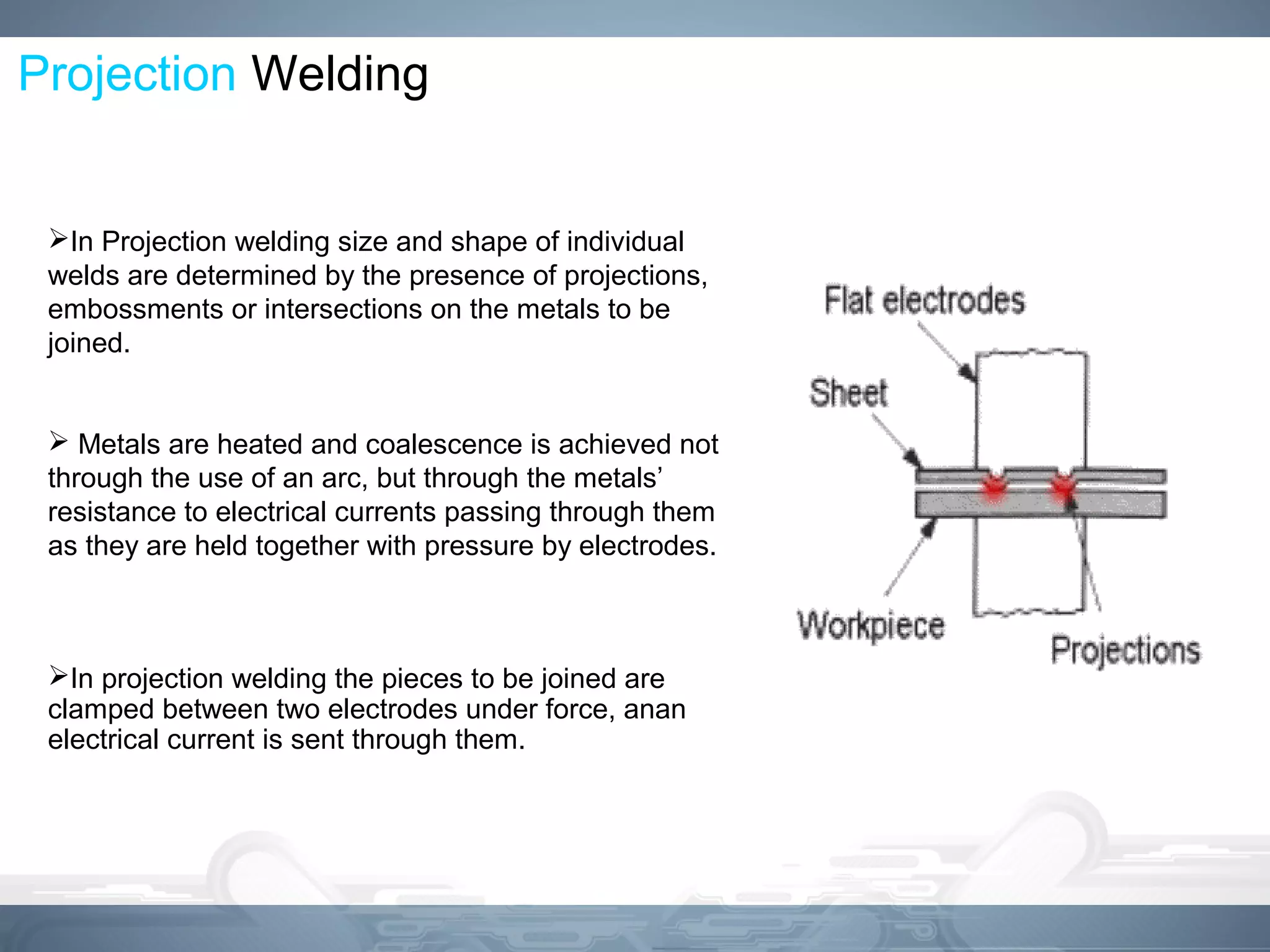

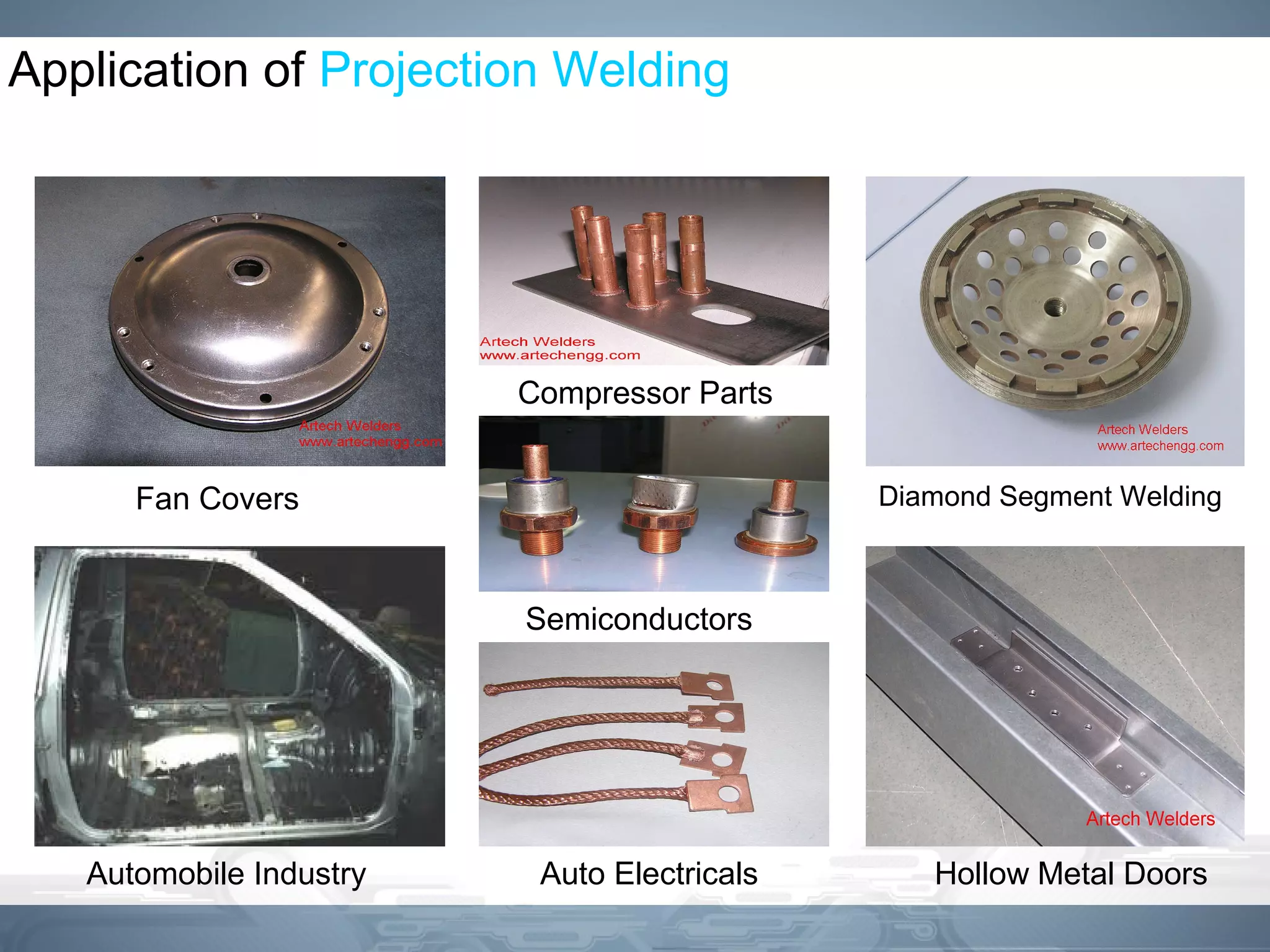

The document discusses spot and projection welding, outlining their processes, advantages, and applications in various industries such as automotive and manufacturing. Spot welding involves clamping metal pieces between electrodes and passing current to achieve fusion, while projection welding uses projections on metals to determine weld size and efficiency. Both methods are noted for their speed, cost-effectiveness, and ability to join multiple sheets without the need for filler materials.