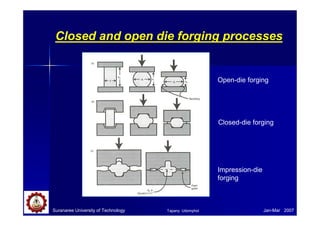

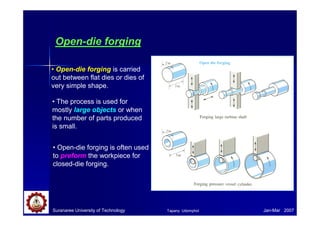

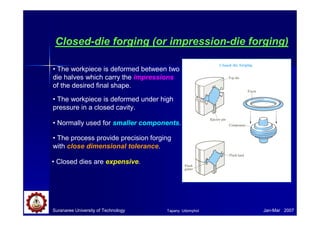

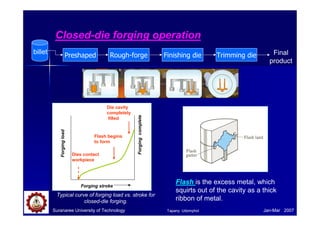

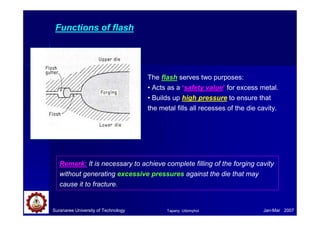

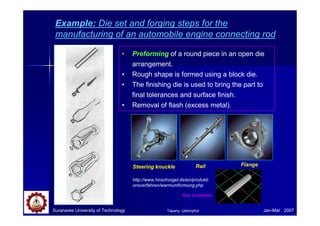

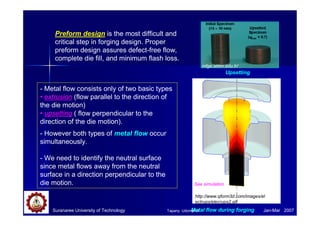

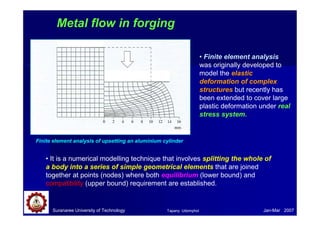

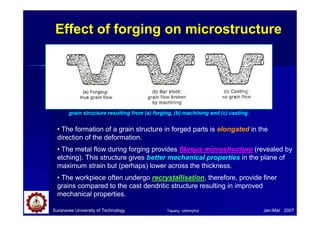

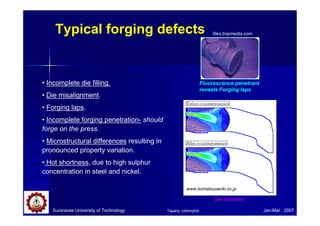

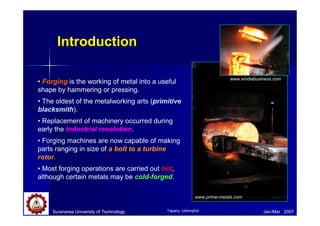

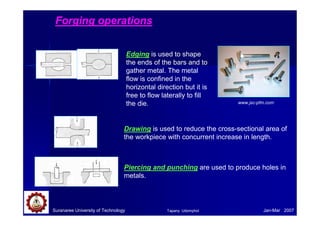

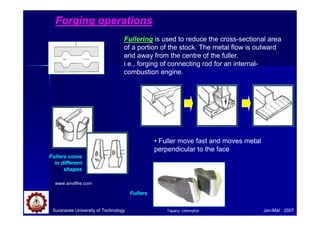

This document provides an overview of metal forging processes. It begins with an introduction to forging and then classifies forging processes into hammer/drop forging and press forging. It further classifies processes as open-die forging or closed-die forging. The document also discusses typical forging operations, the types of forging machines, and provides examples of specific forging processes. It describes the goals of minimizing forging defects and achieving the desired final shape and properties of forged parts.

![Suranaree University of Technology Jan-Mar 2007

Mechanical press forging

Mechanical press

• Crank press translates rotary motion into

reciprocating linear motion of the press slide.

• The ram stroke is shorter than in a hammer or

hydraulic press.

• Presses are rated on the basis of the force

developed at the end of the stroke.

• The blow press is more like squeeze than

like the impact of the hammer, therefore, dies

can be less massive and die life is longer than

with a hammer.

• The total energy supplied during the stroke of

a press is given by

[ ]22

2

1

foIW ωω −=

Where I is moment of inertia of the flywheel

ωωωω is angular velocity, ωωωωo-original, ωωωωf-after deformation, rad.s-1

…Eq 3

Tapany Udomphol](https://image.slidesharecdn.com/02forging-160414134810/85/forging-16-320.jpg)