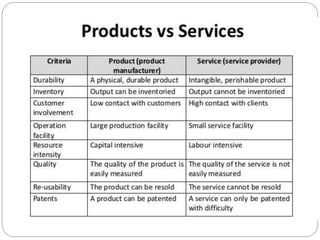

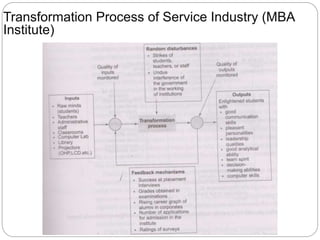

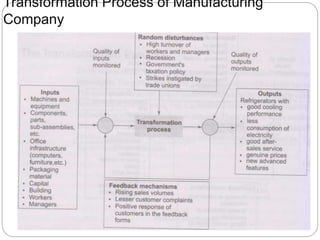

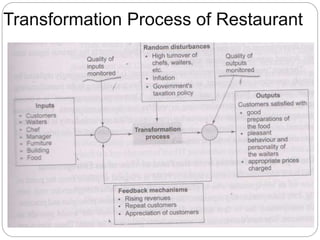

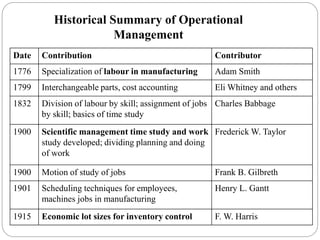

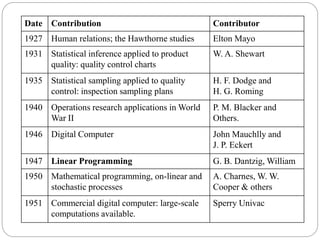

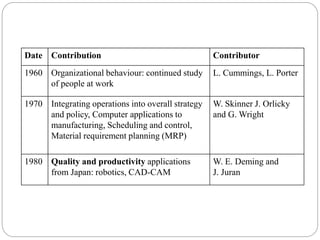

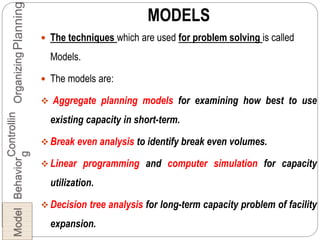

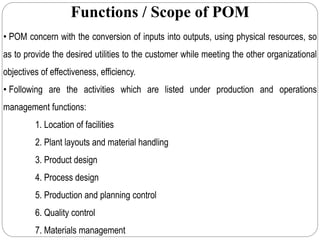

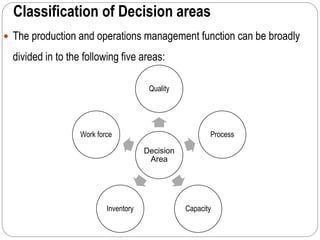

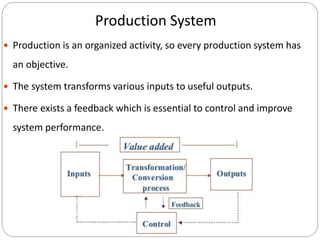

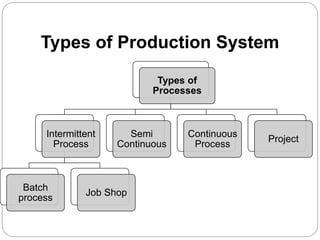

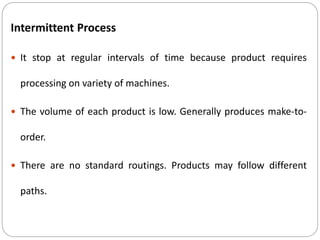

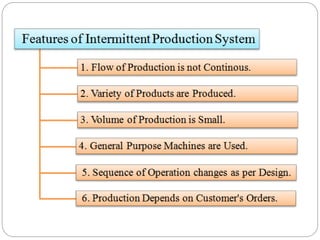

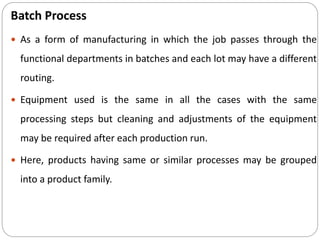

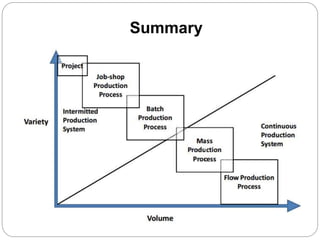

The document provides an overview of production and operations management (POM), detailing its functions, significance, historical contributions, and transformation processes involved in the production of goods and services. It outlines the importance of operations management in optimizing resource use, ensuring quality, and enhancing customer satisfaction, while also describing various manufacturing processes and operational strategies. Additionally, it emphasizes the need for effective planning, organizing, controlling, and understanding employee behavior to achieve operational efficiency.