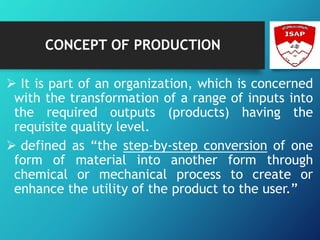

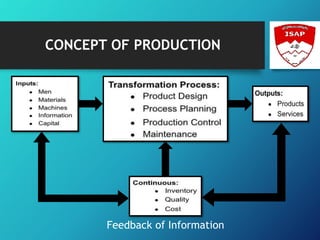

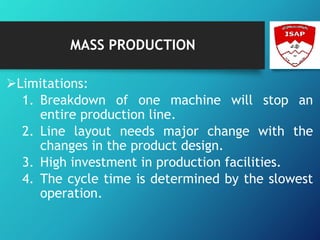

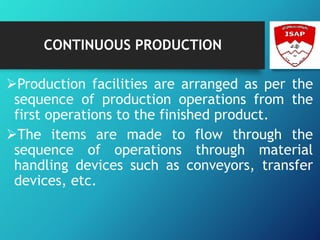

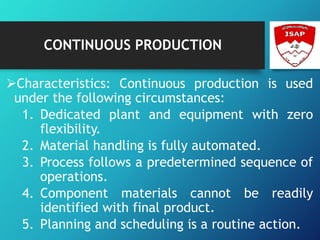

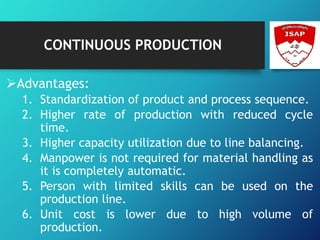

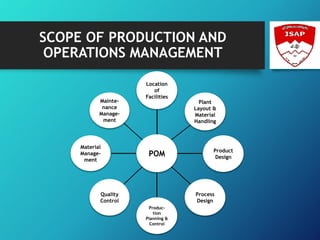

Production and operations management is the process of transforming inputs into outputs through the production subsystem in a controlled manner according to organizational policies. It involves the transformation of various resources into products or services. There are four main types of production systems: job shop production which involves low volume and high variety; batch production which produces limited quantities at regular intervals; mass production which uses dedicated equipment for large volume standardized output; and continuous production where materials flow automatically through dedicated equipment in a predetermined sequence.