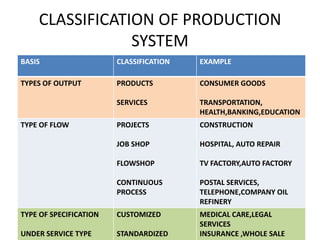

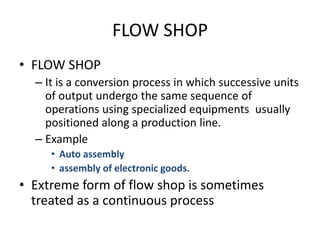

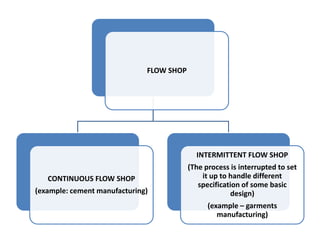

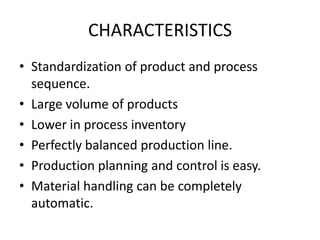

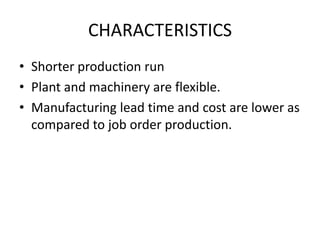

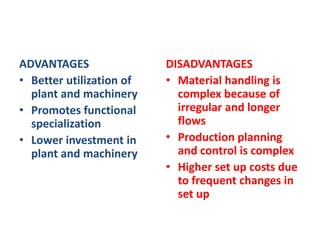

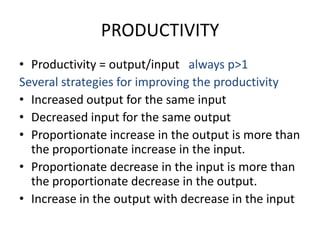

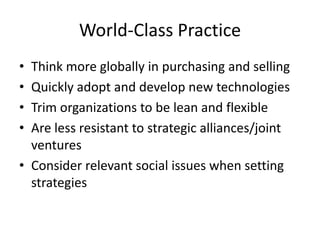

The document provides an overview of operations management. It discusses key historical milestones like the Industrial Revolution and scientific management. It also outlines different production systems like job shop, flow shop and batch manufacturing. Finally, it discusses strategies to improve productivity and competitive advantages of world-class manufacturing like quality, cost effectiveness and on-time delivery.