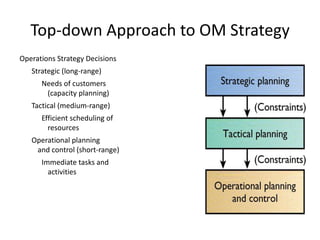

Operations management refers to administering business practices to maximize efficiency and profitability. It involves converting materials and labor into goods and services. The operations function creates and delivers products and services while evaluating quality, quantity, costs and fulfilling customer needs. Mass production and flexible production are two key production methods used. Production managers oversee resources to transform inputs into finished outputs through planning, implementing, and controlling production processes.