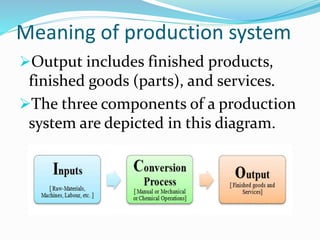

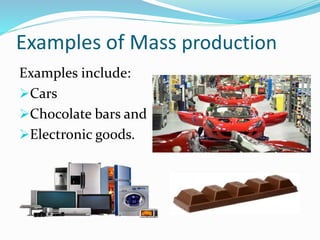

This document discusses different types of production systems. It defines production as manufacturing, mining or growing goods for trade, and a production system as consisting of inputs, conversion processes, and outputs. The main types of production systems are described as job production (one-off custom jobs), batch production (similar goods in batches), mass production (large volumes of standardized goods), and process production (continuous extraction of goods like oil). The advantages and disadvantages of each system are provided.