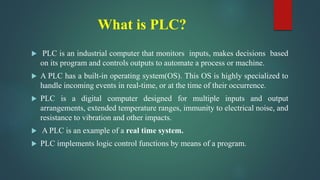

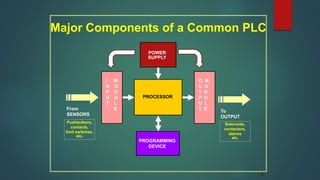

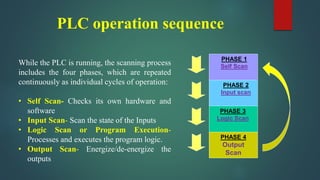

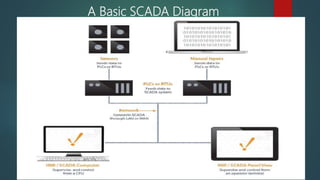

This document is a short term training report on PLC, SCADA, and HMI presented by Rameez Raja. It defines these automation tools and their major components. PLC is an industrial computer that monitors inputs and controls outputs to automate processes. It has a processor, power supply, I/O modules, and programming device. SCADA is a real-time system used to remotely monitor and control industrial equipment. HMI allows human interaction with machines through control panels and input devices. The document discusses PLC operation, ladder logic, advantages and applications of PLC and SCADA, and concludes with thanking the audience.

![A

Short Term Training Report

on

PLC SCADA And HMI

PRESENTED BY:

Rameez Raja

MUR1300087

B.Tech ECE 3rd Yr.

GUIDED BY :

MR. PAWAN KUMAR

Tech. Head of Automation

[IGTR, Aurangabad]](https://image.slidesharecdn.com/plc8rajapresentationplc-170316194604/85/Plc-8-raja-presentation-plc-1-320.jpg)