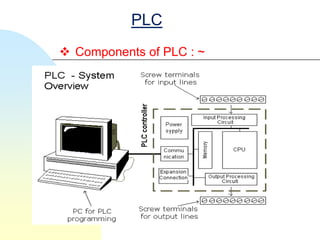

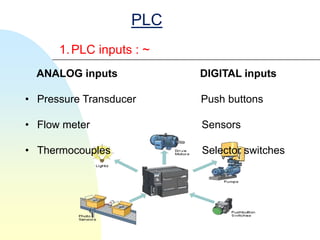

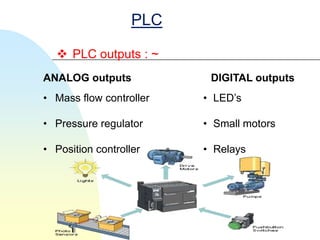

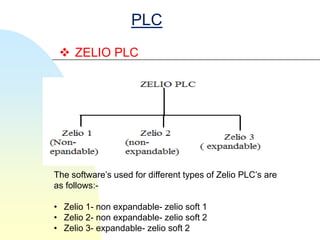

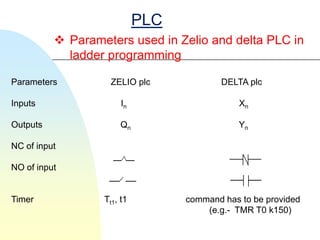

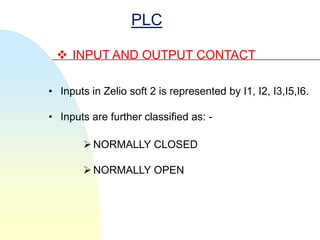

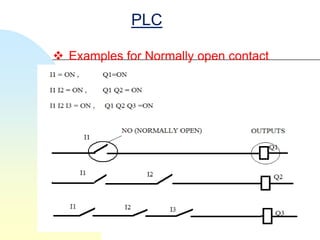

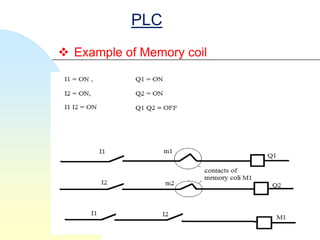

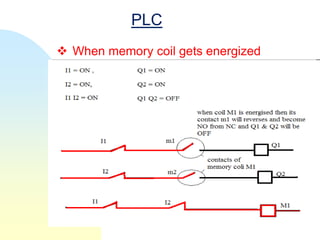

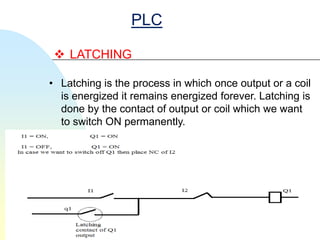

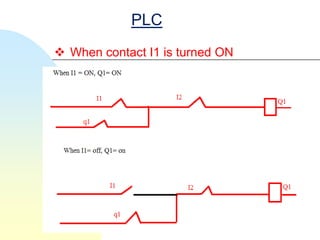

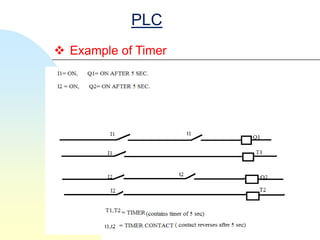

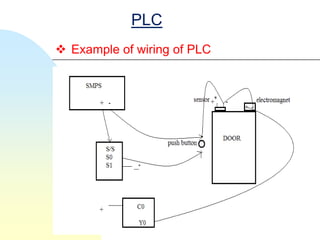

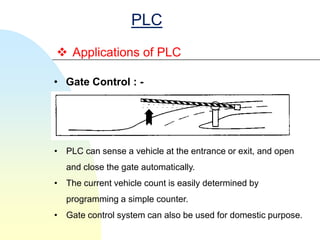

The document discusses automation and its various components. Automation is the use of control systems and information technologies to perform processes automatically with minimal human intervention. It discusses programmable logic controllers (PLCs) as a key tool of automation. PLCs are special computers used to control industrial processes. The document then describes the basic components, programming, and applications of PLCs.