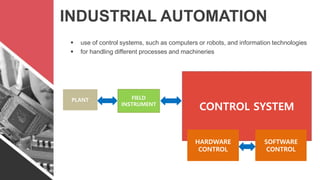

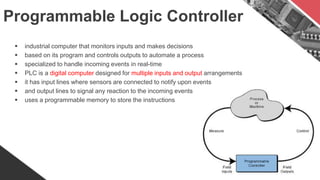

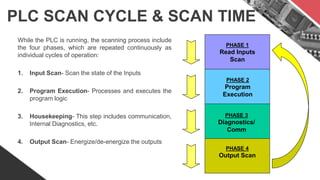

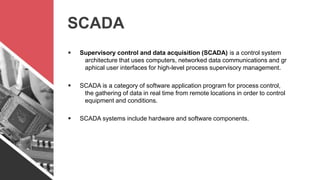

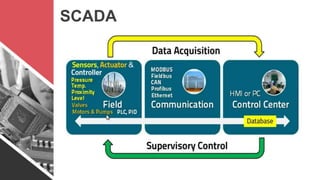

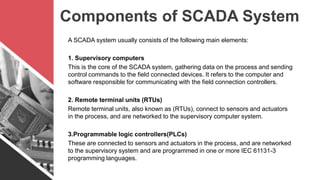

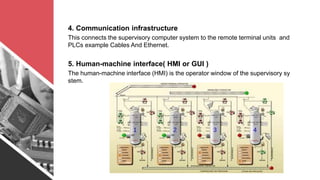

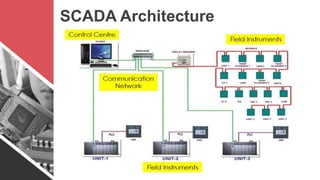

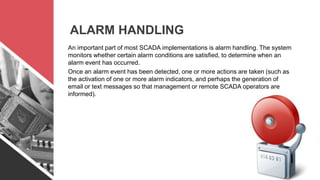

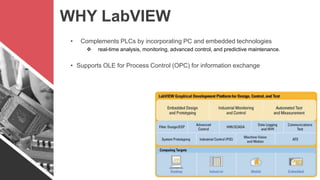

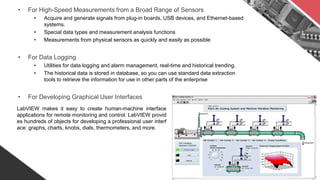

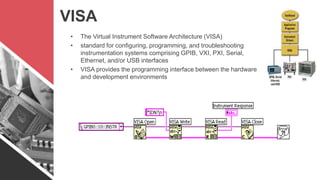

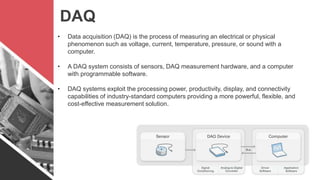

The document provides an overview of industrial automation, highlighting its components like PLCs and SCADA systems, which help enhance productivity, quality, and safety through automation technologies. It discusses the functionalities of various control systems, including real-time data acquisition and alarm handling, while emphasizing the importance of programming skills in this field. Additionally, it references tools like LabVIEW and Virtual Instrument Software Architecture (VISA) that support the development of effective automation solutions.