The document provides details about an internship project on PLC, SCADA and automation completed by Varun Kumar Raghav at Sofcon India Pvt. Ltd. It includes an acknowledgement, abstract, certificate of completion, table of contents and chapters covering company profile, introduction to automation, PLC programming and operation, SCADA software and applications. The internship helped provide hands-on experience with PLC and SCADA systems and their uses in industrial automation.

![[i]

INDUSTRIAL TRAINING AND PROJECT REPORT

On

PLC SCADA AND AUTOMATION

BY

VARUN KUMAR RAGHAV (1703221107)

SUBMITTED TO THE DEPARTMENT OF ELECTRICAL AND ELECRONICS ENGINEERINGIN

PARTIAL FULFILLMENT OF THE REQUIREMENS

FOR THE DEGREE OF BACHELOR OF

TECHNOLOGY

IN

ELECTRICAL AND ELECRONICS ENGINEERINGING

ABES Engineering college Ghaziabad

Dr. APJ Abdul Kalam technical university Uttar Pradesh Lucknow](https://image.slidesharecdn.com/finalrepotofsummerinternship-201001035954/75/summer-internship-report-on-PLC-SCADA-1-2048.jpg)

![[ii]

ACKNOWLEDGEMENT

I feel profound happiness in forwarding this industrial training report as an image

of sincere efforts. It is almost inevitable to ensure indebtedness to all who

generously helped by sharing their valuable experience & devoting their precious

time with us, without whom this seminar report would have never been

accomplished.

First & foremost I extend my thanks & gratitude to the entire unit of “SOFCON

INDIAN PVT.LTD. NOIDA” along with “Mr. PUSHKAR BAJPAYEE

(DIRECTOR)”,“Mr. PRAVEEN KUMAR (Assistant Professor)” whose

guidance, teaching and invaluable suggestions provided me a deep insight in my

chosen field of technology, enhanced my knowledge and supported in widening

my outlook towards the communication industry. I am also very thankful to all the

engineers of the department for their kind support throughout the training.](https://image.slidesharecdn.com/finalrepotofsummerinternship-201001035954/85/summer-internship-report-on-PLC-SCADA-2-320.jpg)

![[iii]

ABSTRACT

Industrial training is must for every student perusing professional degree because

the ultimate goal of every student is to get the information the industrial training

helps us to get an idea of the things. We should know in order to get a job i.e. I

have a good professional career. Industrial training teaches us lots of things. it

helps us to know the kind of environment we would be getting in the industry and

help us to get with the kind of environment. The totality the industrial teaches us

industrial ethics. Some advance technical how and help us to acquire with

industrial working style. Supervisory control and data acquisition (SCADA) allows

a utility operator to monitor and control processes that are distributed among

various remote sites. SCADA, is a system for gathering real time data, controlling

processes, and monitoring equipment from remote locations. As more companies

are implementing an open SCADA architecture through the Internet to monitor

critical infrastructure components such as power plants, oil and gas pipelines,

chemical refineries, flood control dams, and waste and water systems, vital

systems are becoming increasingly open to attack. This report provides an

overview of SCADA, outlines several vulnerabilities of SCADA systems, presents

data on known and possible threats, and provides particular remediation strategies

for protecting these systems. PLCs are used in many different industries and

machines such as packaging and semiconductor machines. Programs to control

machine operation are typically stored in battery-backed or non-volatile memory.

A programmable logic controller (PLC) or programmable controller is a digital

computer used for automation of electromechanical processes, such as control of

machinery on factory assembly lines, amusement rides, or lighting fixtures. PLCs

are used in many industries and machines. Unlike general-purpose computers, the

PLC is designed for multiple inputs and output arrangements, extended

temperature ranges, immunity to electrical noise, and resistanc e to vibration and

impact.](https://image.slidesharecdn.com/finalrepotofsummerinternship-201001035954/85/summer-internship-report-on-PLC-SCADA-3-320.jpg)

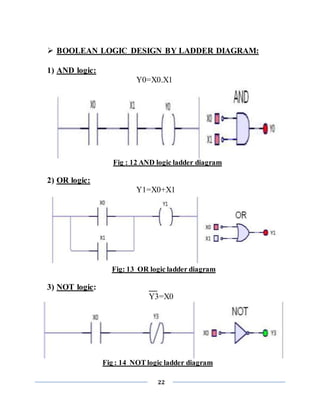

![16

contacts which pass on from left to right the condition "ON" or "OFF" which

correspond to the Boolean values TRUE and FALSE. To each contact belongs a

Boolean variable. If this variable is TRUE, then the condition is passed from left to

right along the connecting line. Otherwise the right connection receives the value

OFF.

INPUT represented by (I)

OUTPUT represented by (O)

Addressing method:

1 slot=32 bit=2 word (1 char. / word=2 byte=16 bit)

Input addressing:

File letter: Slot number. Word number/Bit number

Forexample:- I:2.1/1

Output addressing:

File letter: Slot number. Word number/Bit number

Forexample:- O:2.1/1

GENERALLY USED INSTRUCTIONS & SYMBOL FOR

PLC PROGRAMMING:-

Input Instruction:

1) --[ ]—

This Instruction is Called XIC or Examine If Closed. ie; If a NO

switch is actuated then only this instruction will be true. If a NC switch is

actuated then this instruction will not be true and hence output will not be

generated.

2) --[]—

This Instruction is Called XIO or Examine If Open ie; If a

NC switch is actuated then only this instruction will be true. If a NC

switch is actuated then this instruction will not be true and hence output

will not be generated.](https://image.slidesharecdn.com/finalrepotofsummerinternship-201001035954/85/summer-internship-report-on-PLC-SCADA-16-320.jpg)

![21

2) CTD: Count Down

Decrements the accumulate value at each false-to true

transition and retains the accumulated value when the instruction goes false or

when power cycle occurs.

Fig: 10 Count Down

Addressing of counter:

Fig: 11 Addressing of timer

RESET: --(RES)--

Reset the accumulated value and status bits of a timer or counter.

A C5:0

-------[ ]---------------------(RES)--------------------------

When A is true than counter C5:0 is reset.](https://image.slidesharecdn.com/finalrepotofsummerinternship-201001035954/85/summer-internship-report-on-PLC-SCADA-21-320.jpg)

![26

SCADA

(SUPERVISORY CONTROL AND DATA ACQUISITION)

INTRODUCTION

SCADA stands for Supervisory Control And Data Acquisition. As the name

indicates, it is not a full control system, but rather focuses on the supervisory level.

As such, it is a purely software package that is positioned on top of hardware to

which it is interfaced, in general via Programmable Logic Controllers (PLCs), or

other commercial hardware modules.

SCADA systems are used to monitor and

control a plant or equipment in industries such as telecommunications, water and

waste control, energy, oil and gas refining and transportation. These systems

encompass the transfer of data between a SCADA central host computer and a

number of Remote Terminal Units (RTUs) and/or Programmable Logic Controllers

(PLCs), and the central host and the operator terminals. A SCADA system gathers

information (such as where a leak on a pipeline has occurred), transfers the

information back to a central site, then alerts the home station that a leak has

occurred, carrying out necessary analysis and control, such as determining if the

leak is critical, and displaying the information in a logical and organized fashion.

SCADA systems consistof:

1) One or more field data interface devices, usually RTUs, or PLCs, which

interface to field sensing devices and local control switchboxes and valve

actuators.

2) A communications system used to transfer data between field data interface

devices and control units and the computers in the SCADA central host. The

system can be radio, telephone, cable, satellite, etc., or any combination of

these.

3) A central host computer server or servers (sometimes called a SCADA

Center, master station, or Master Terminal Unit (MTU).

4) A collection of standard and/or custom software [sometimes called Human

Machine Interface (HMI) software or Man Machine Interface (MMI)

software] systems used to provide the SCADA central host and operator](https://image.slidesharecdn.com/finalrepotofsummerinternship-201001035954/85/summer-internship-report-on-PLC-SCADA-26-320.jpg)