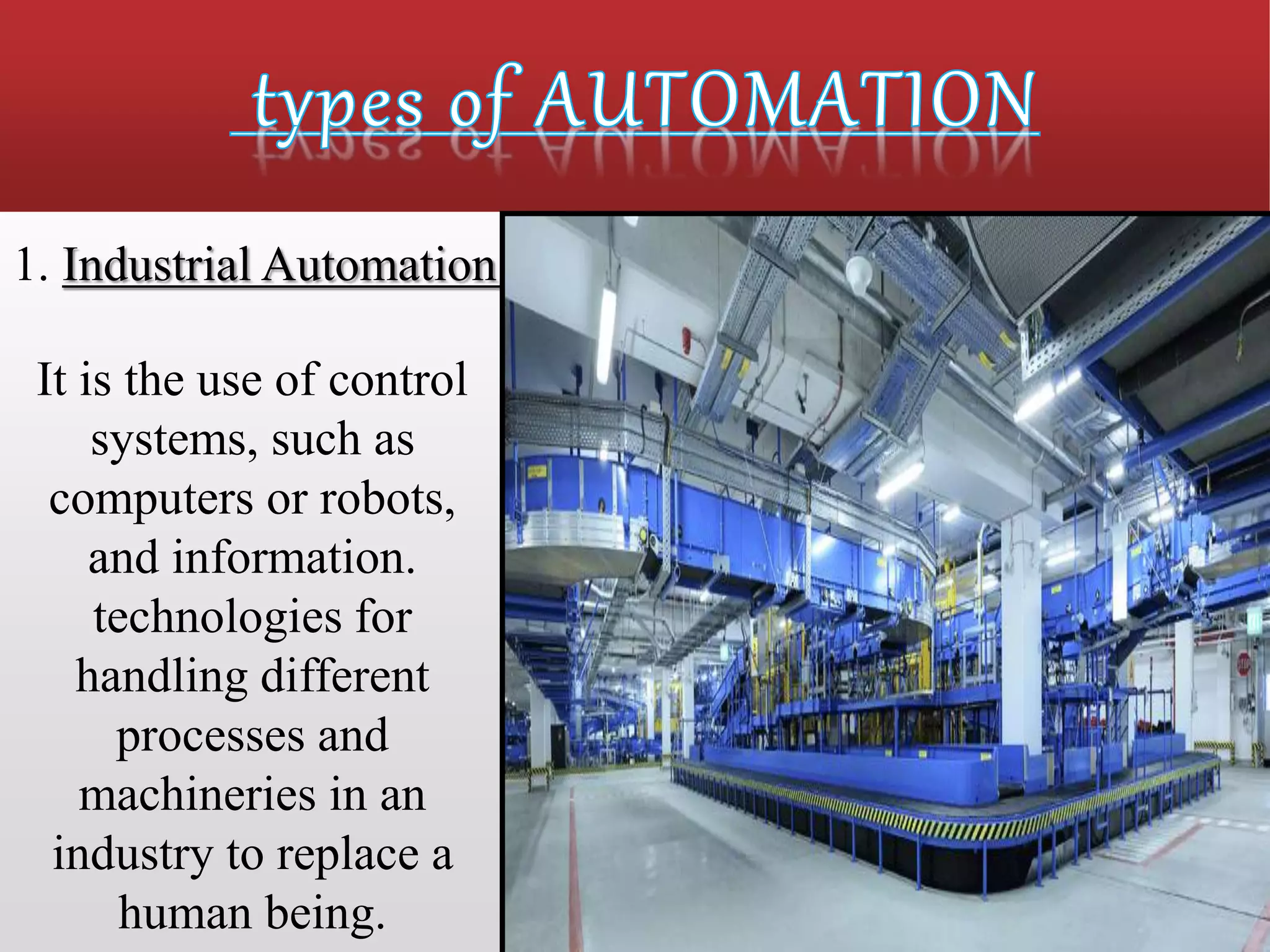

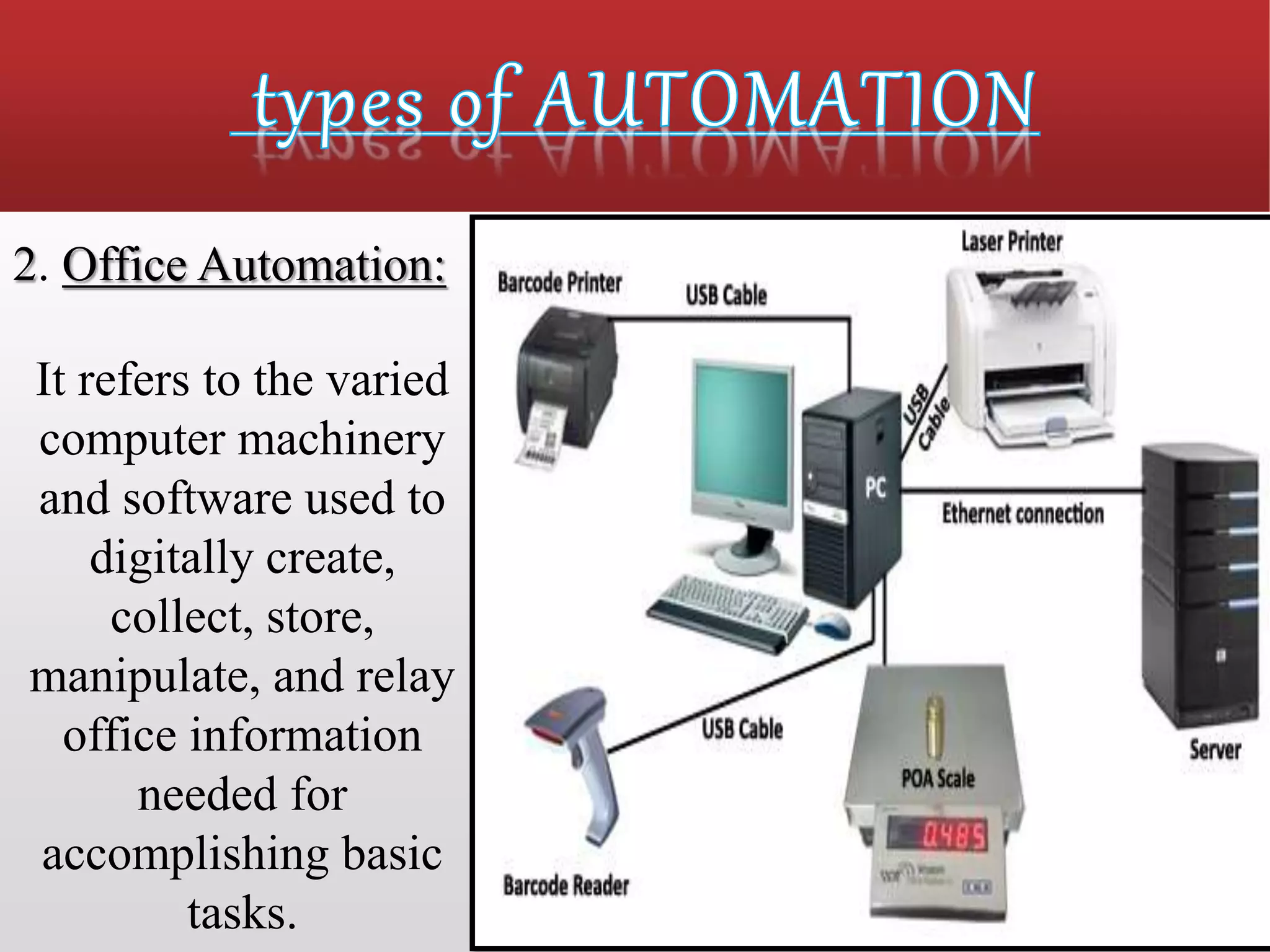

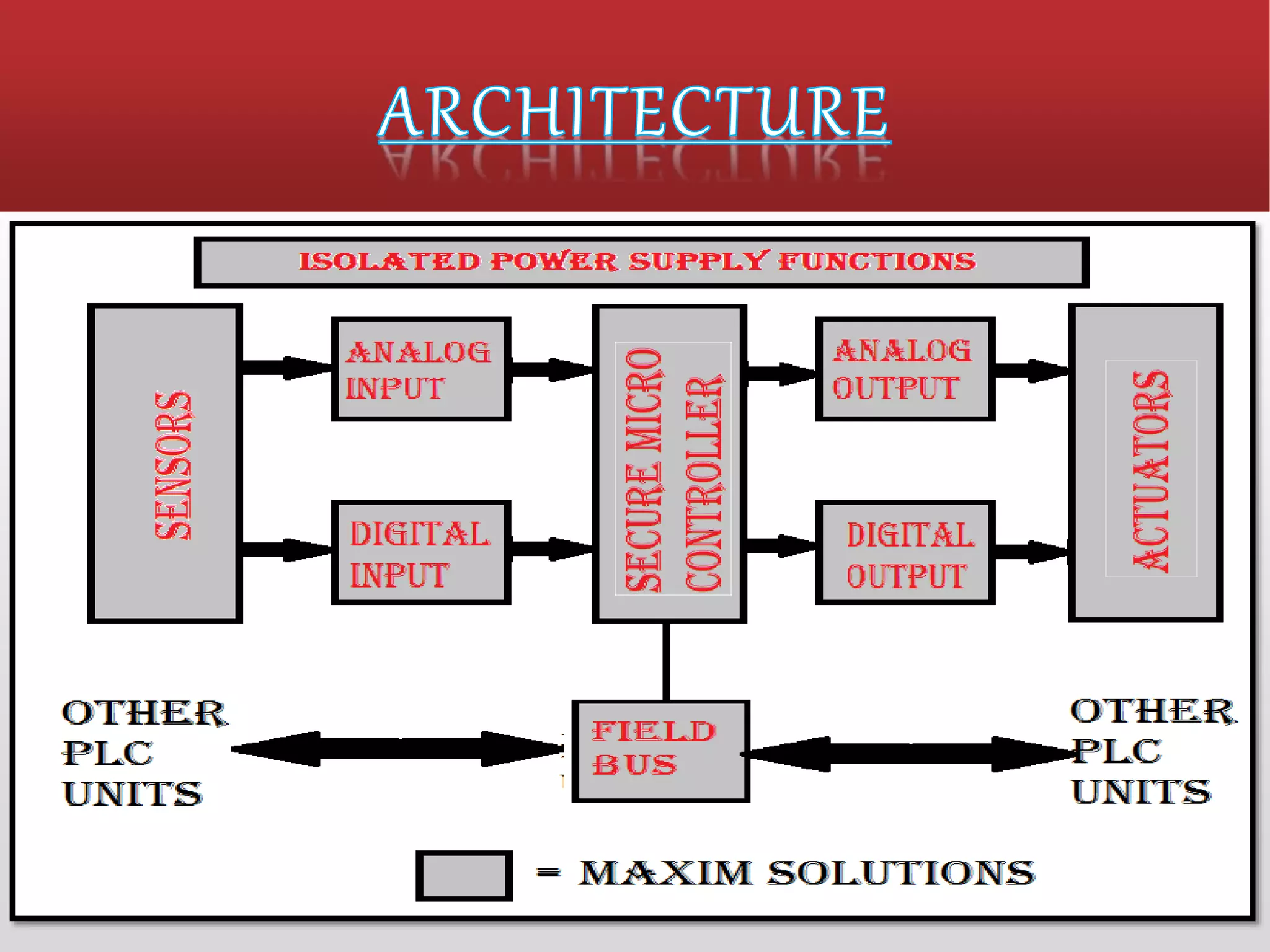

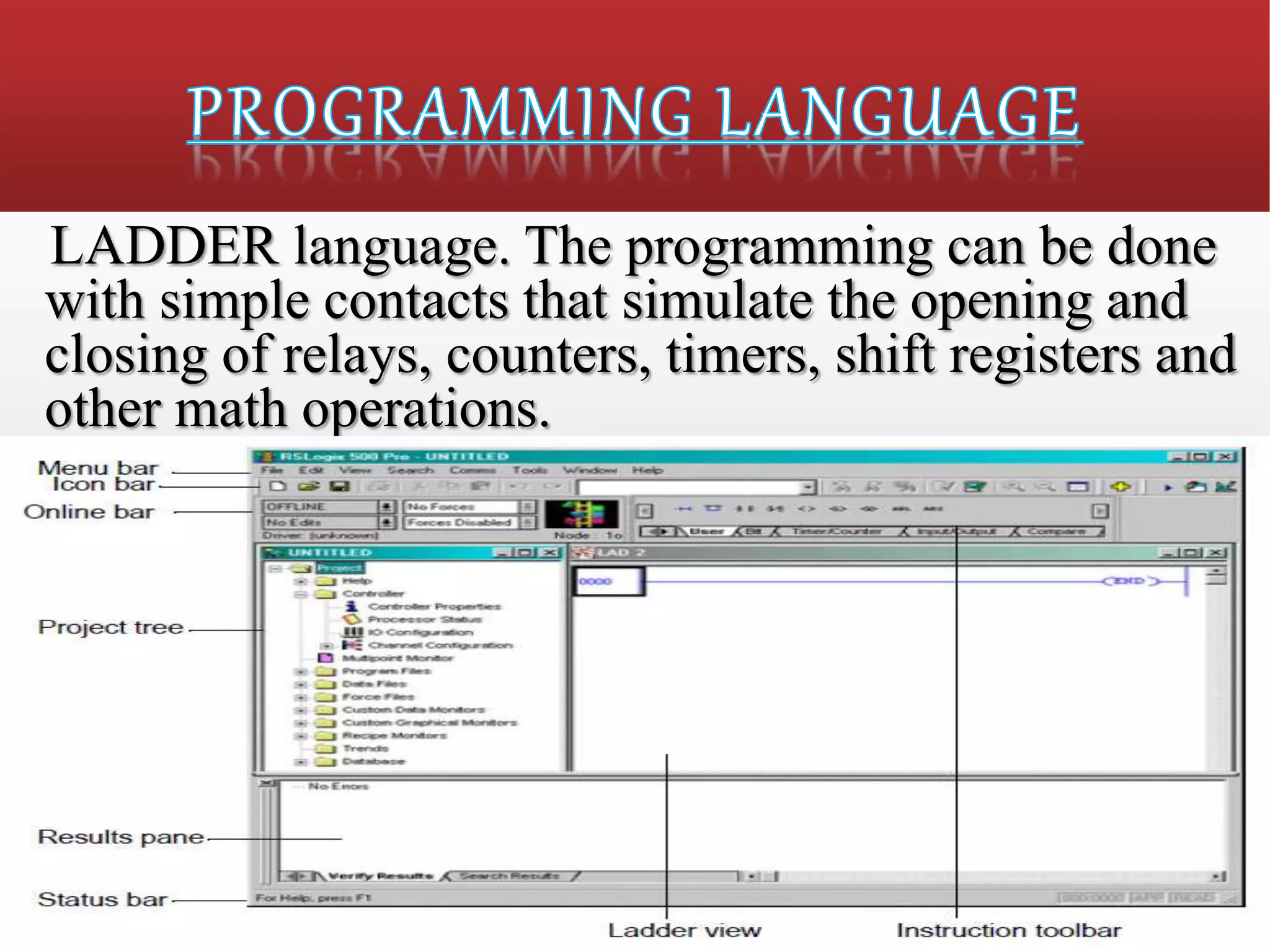

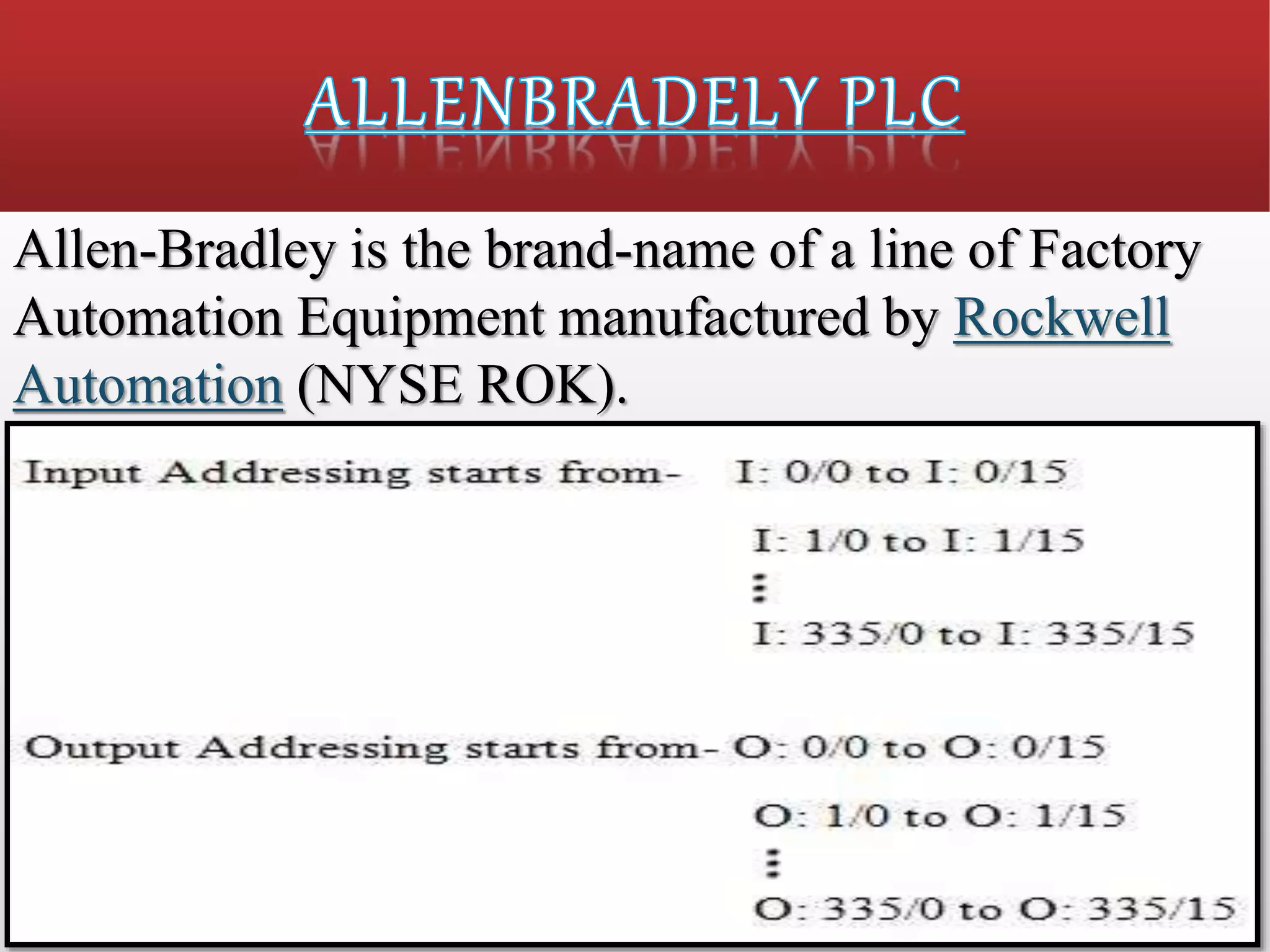

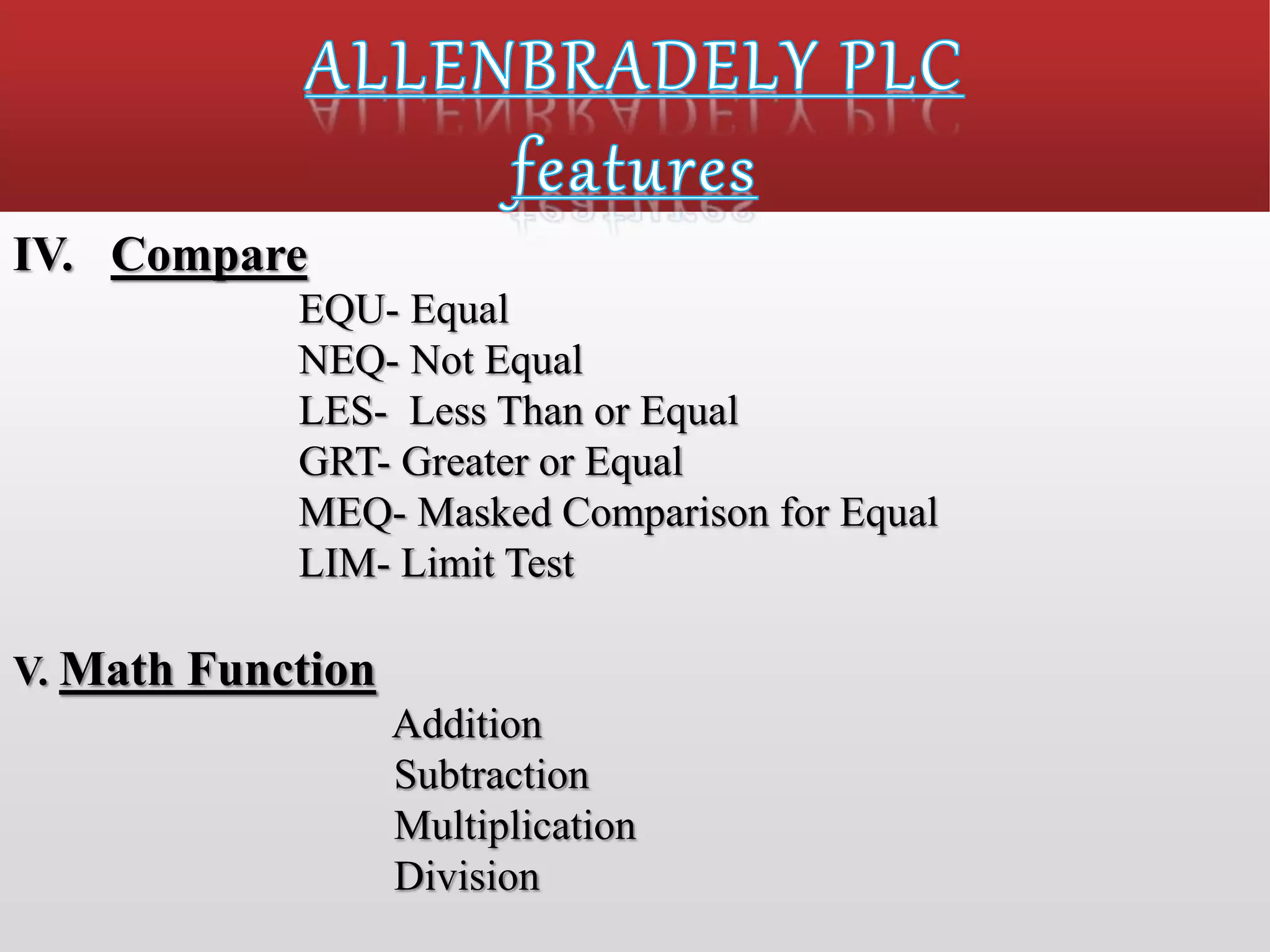

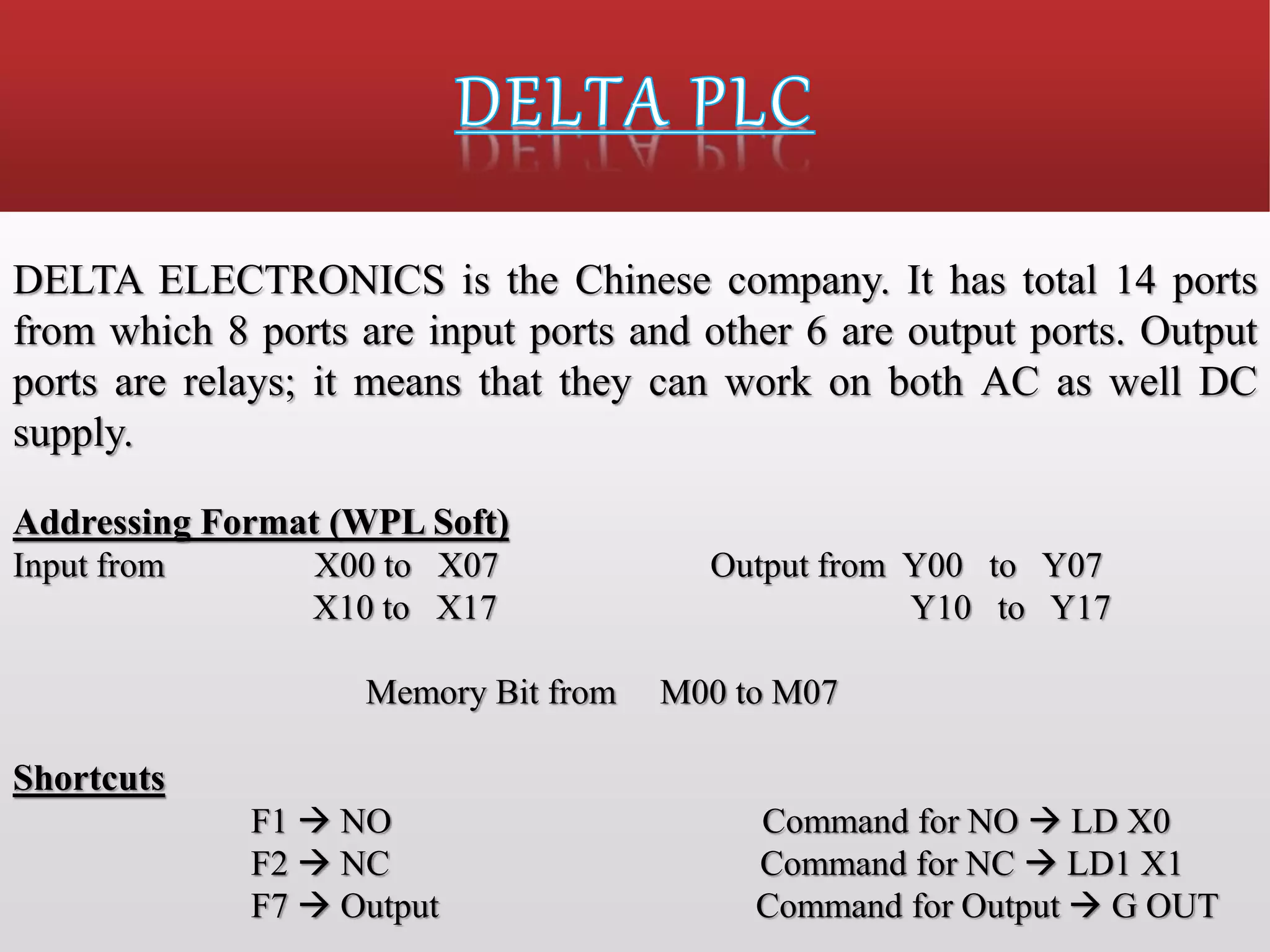

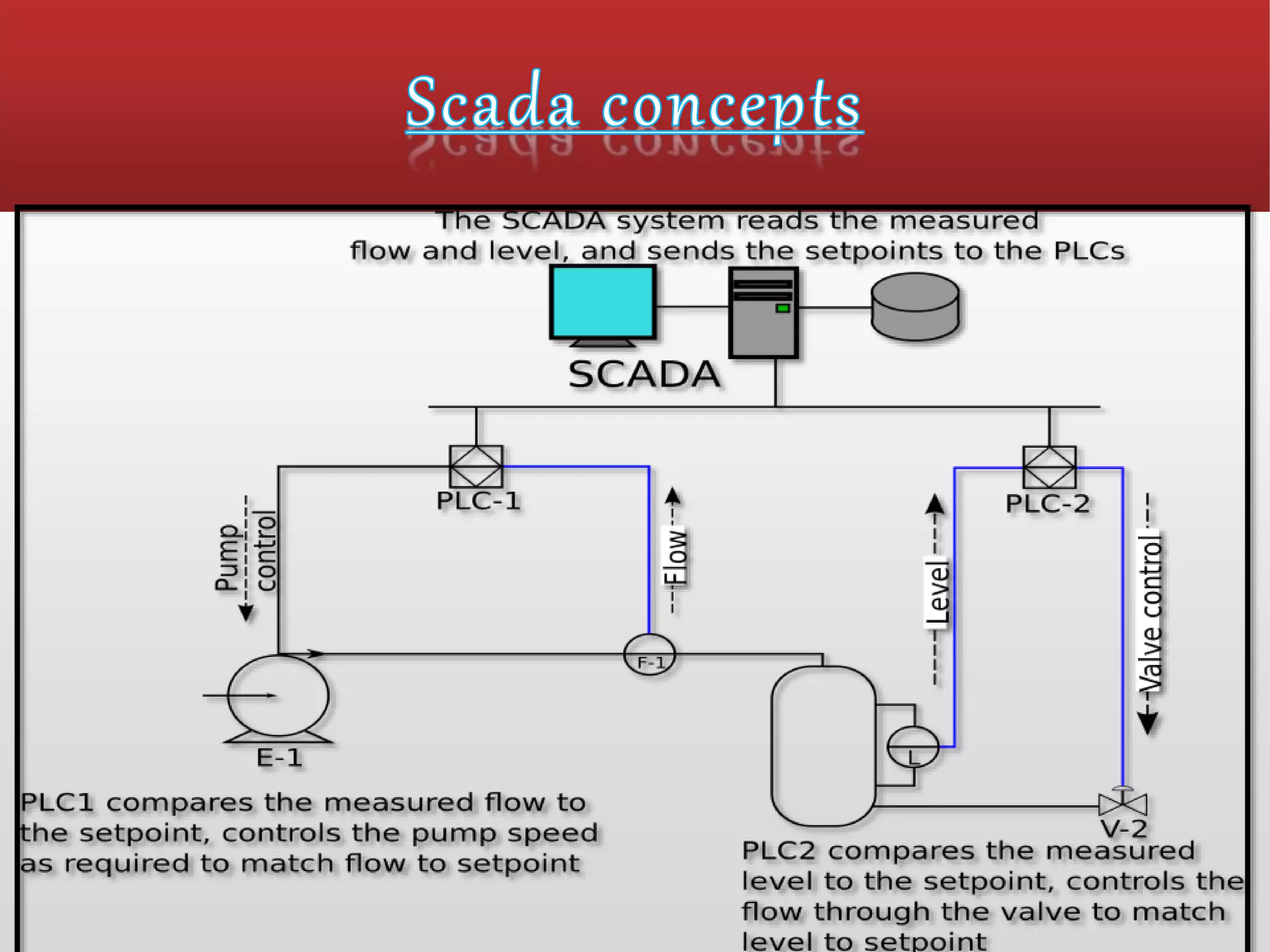

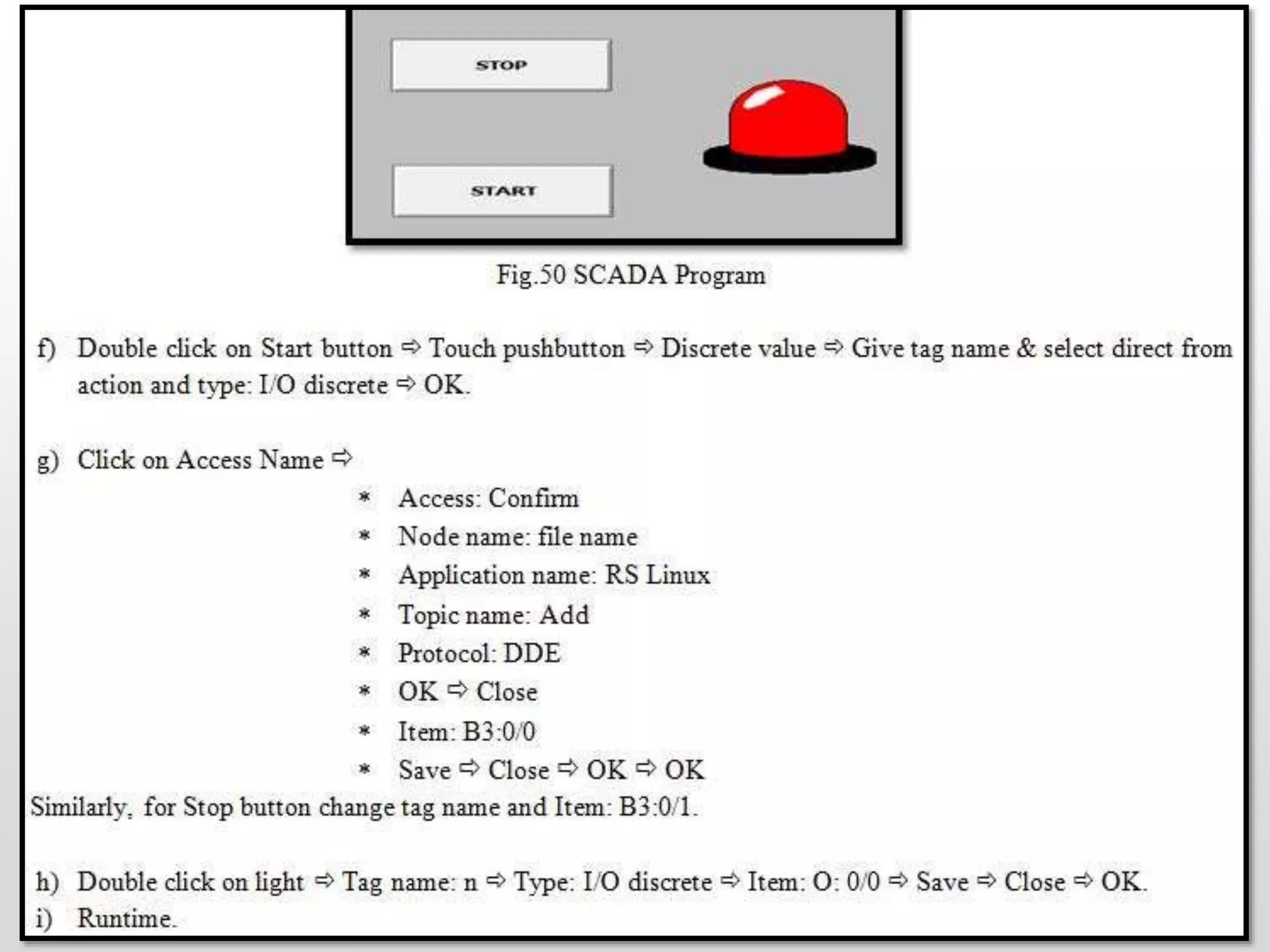

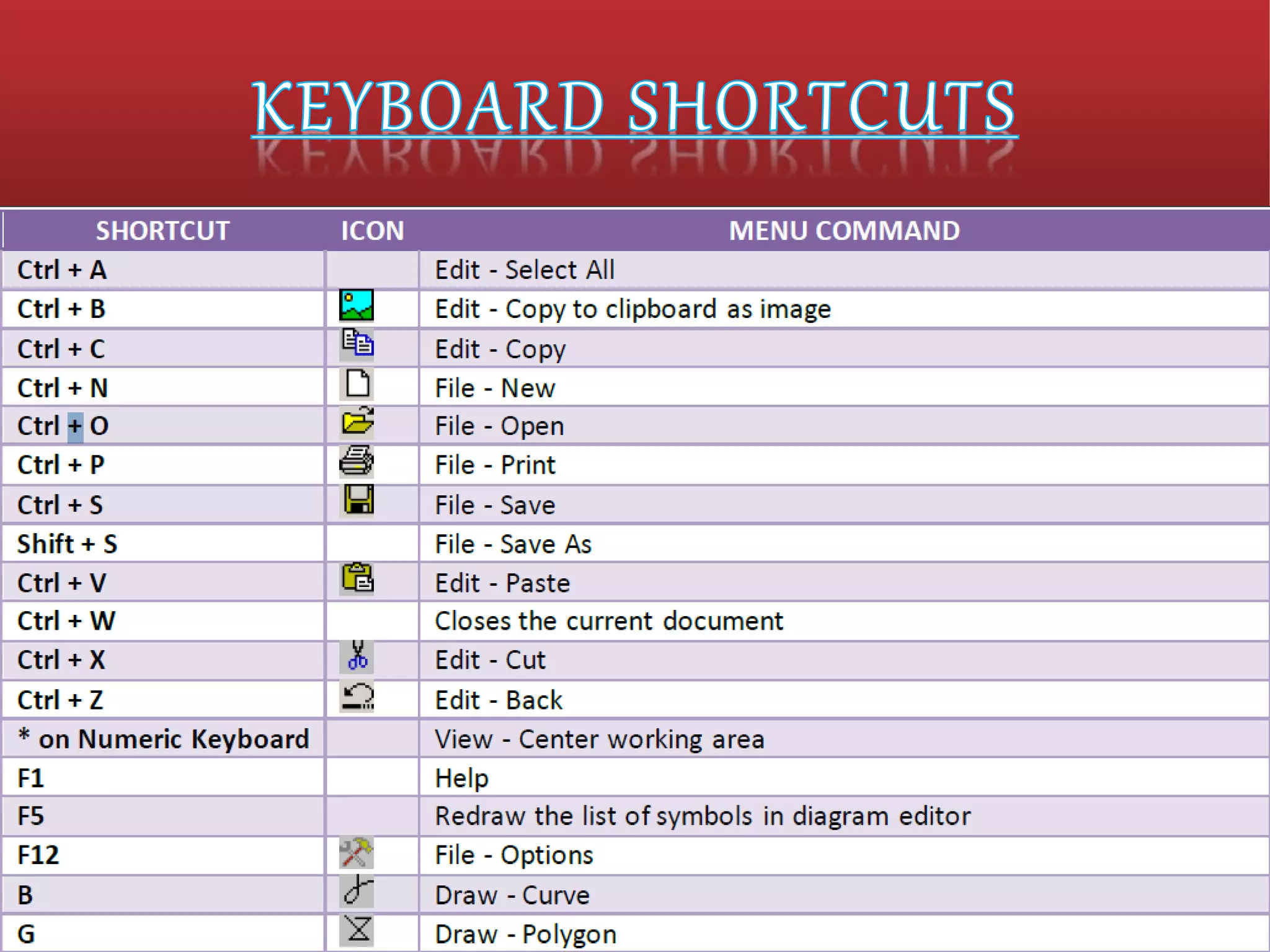

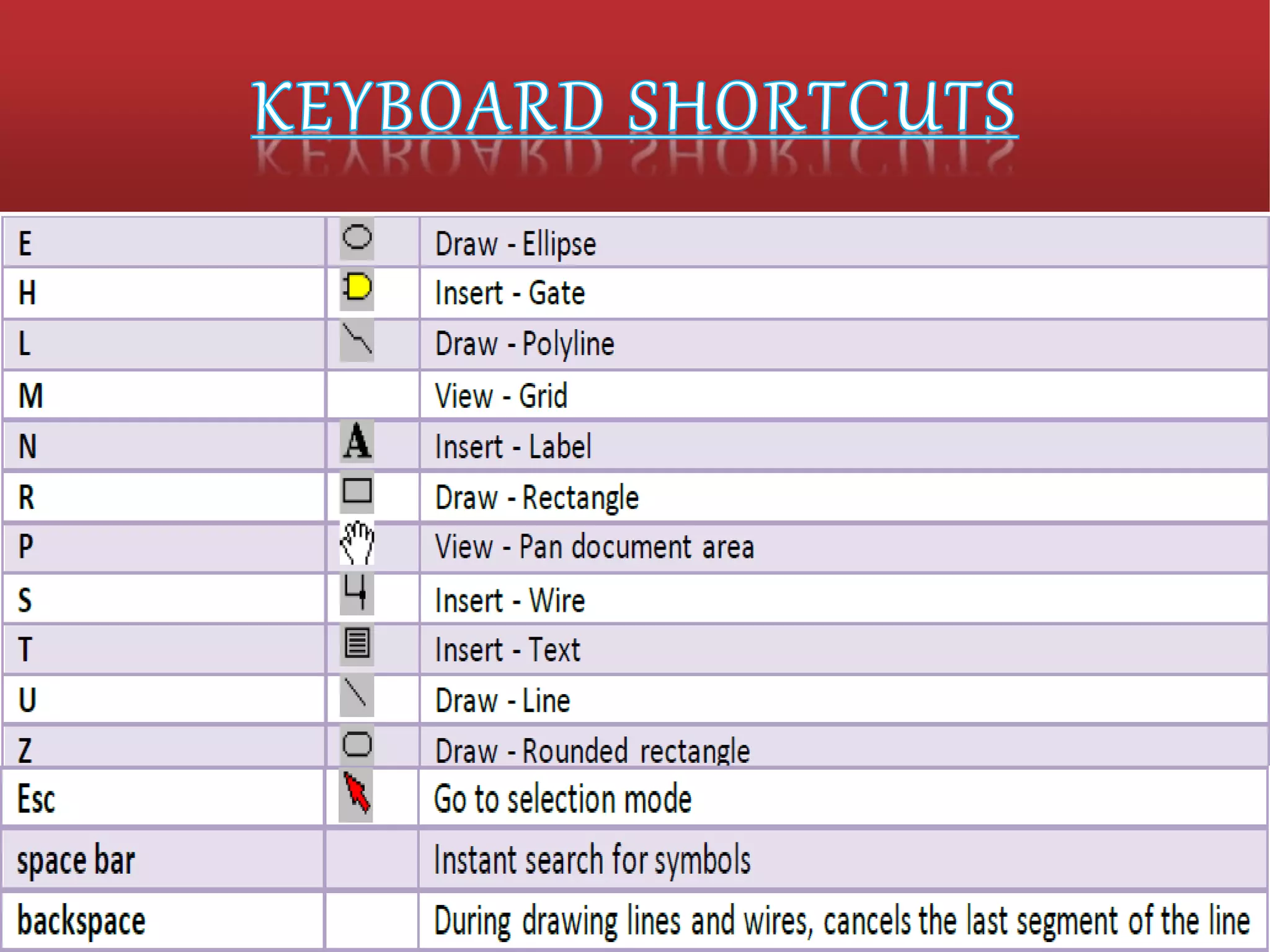

The document discusses various aspects of automation including industrial, office, scientific, biomedical, and transportation automation, highlighting its benefits like increased productivity and improved quality, as well as challenges such as high initial costs and limitations in task automation. It also details programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems, emphasizing their roles in controlling and processing industrial machinery and processes. Furthermore, it covers human-machine interfaces (HMIs) and the use of electrical CAD software to improve design tasks and productivity.