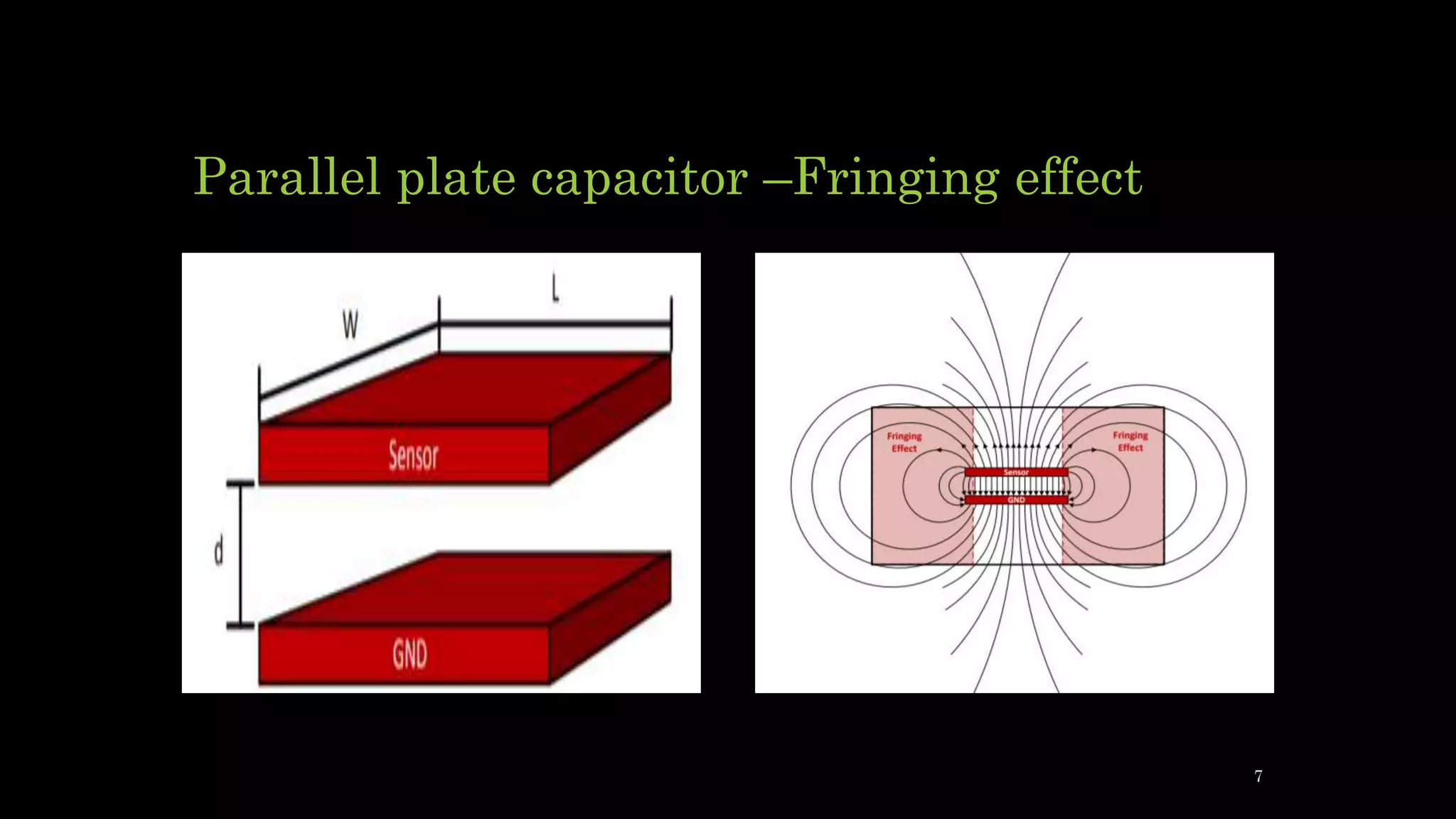

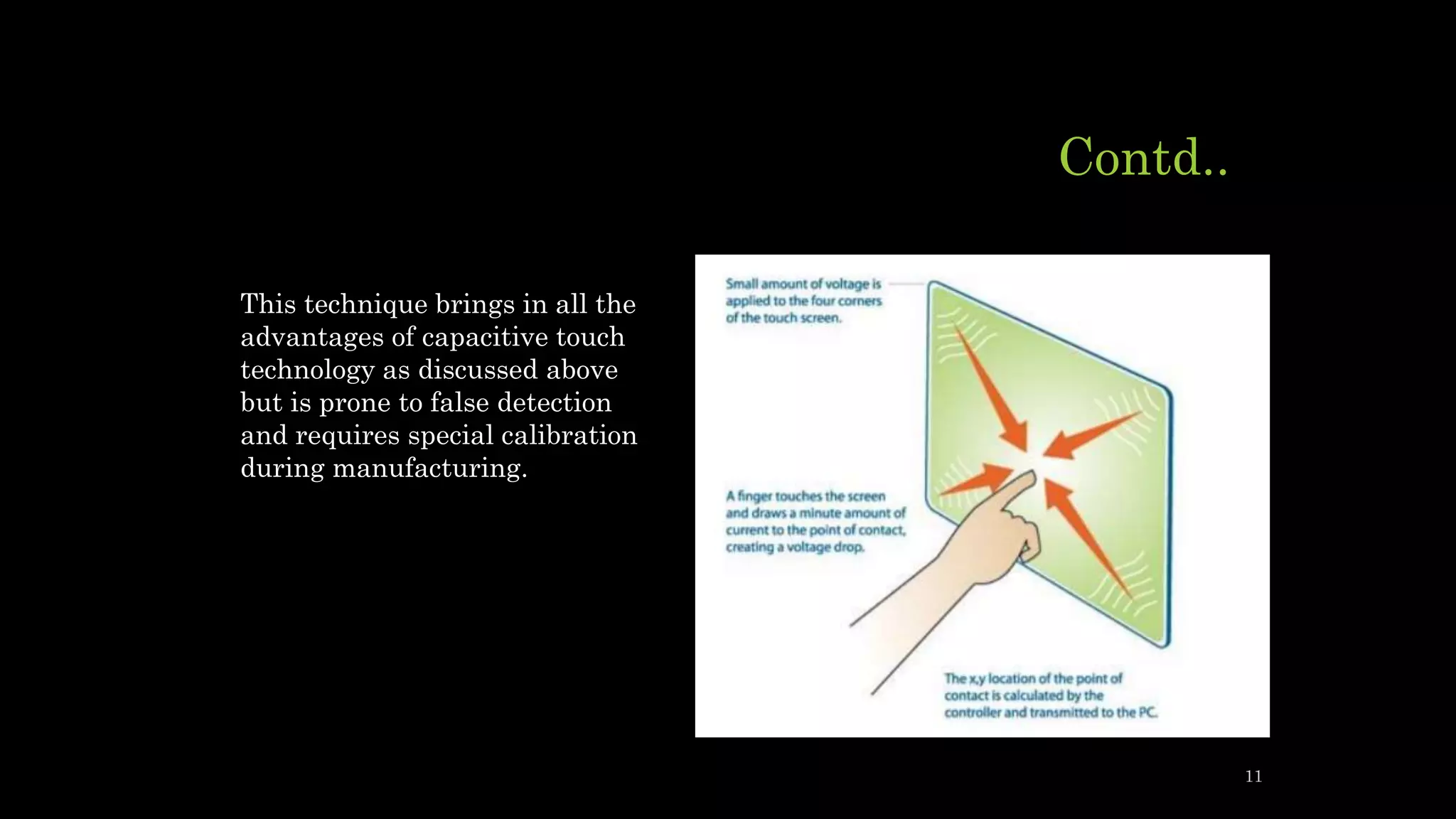

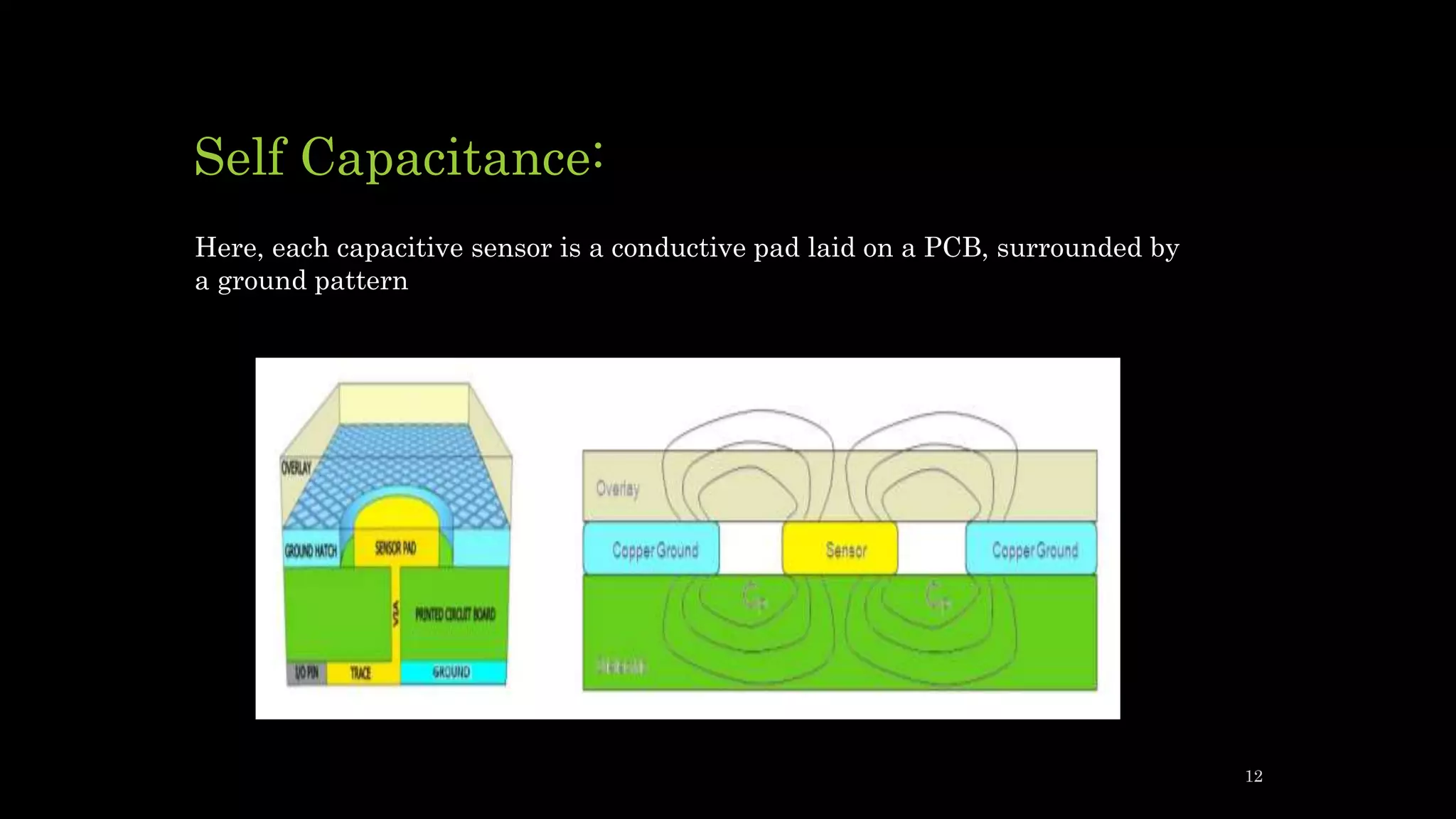

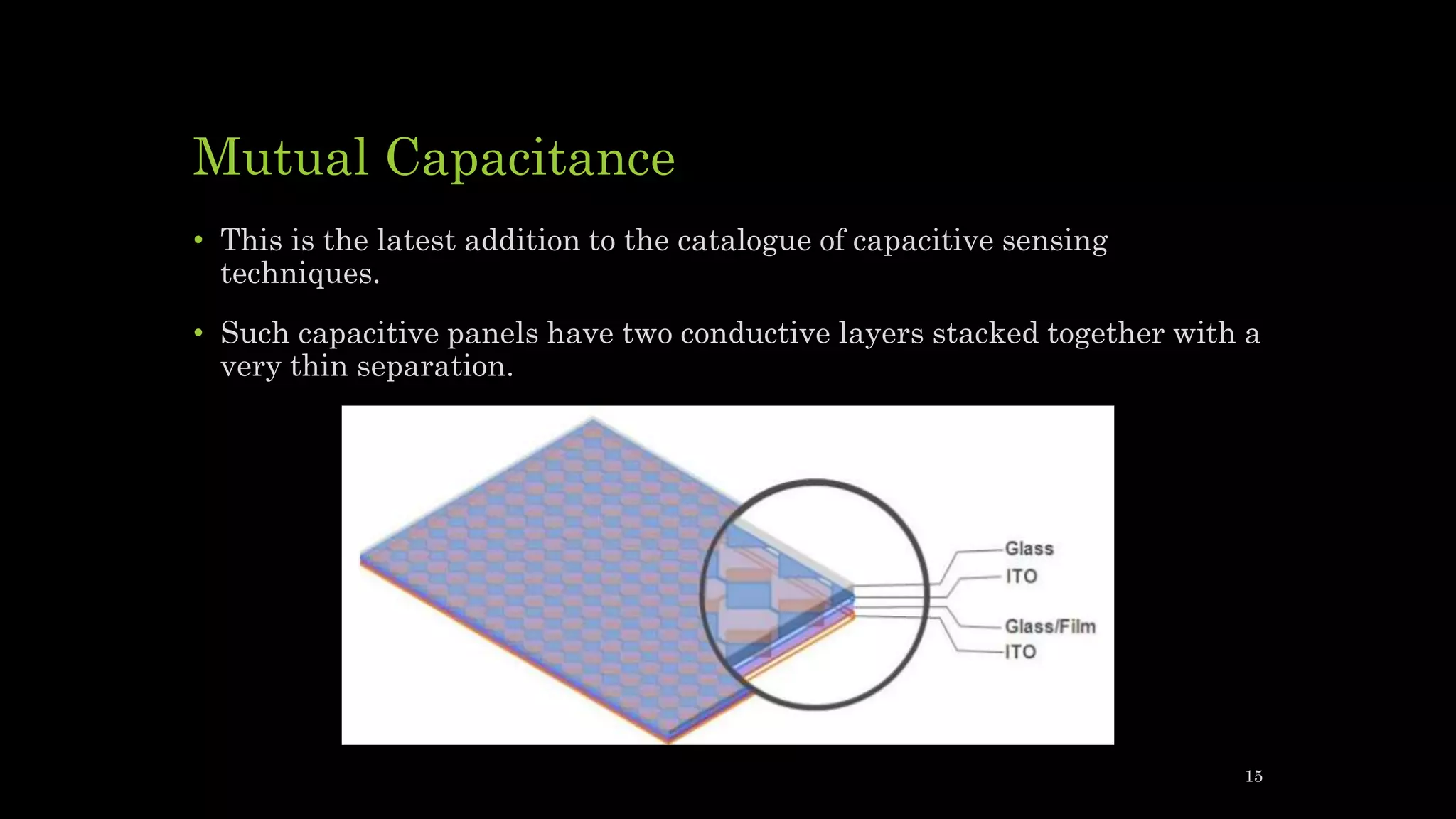

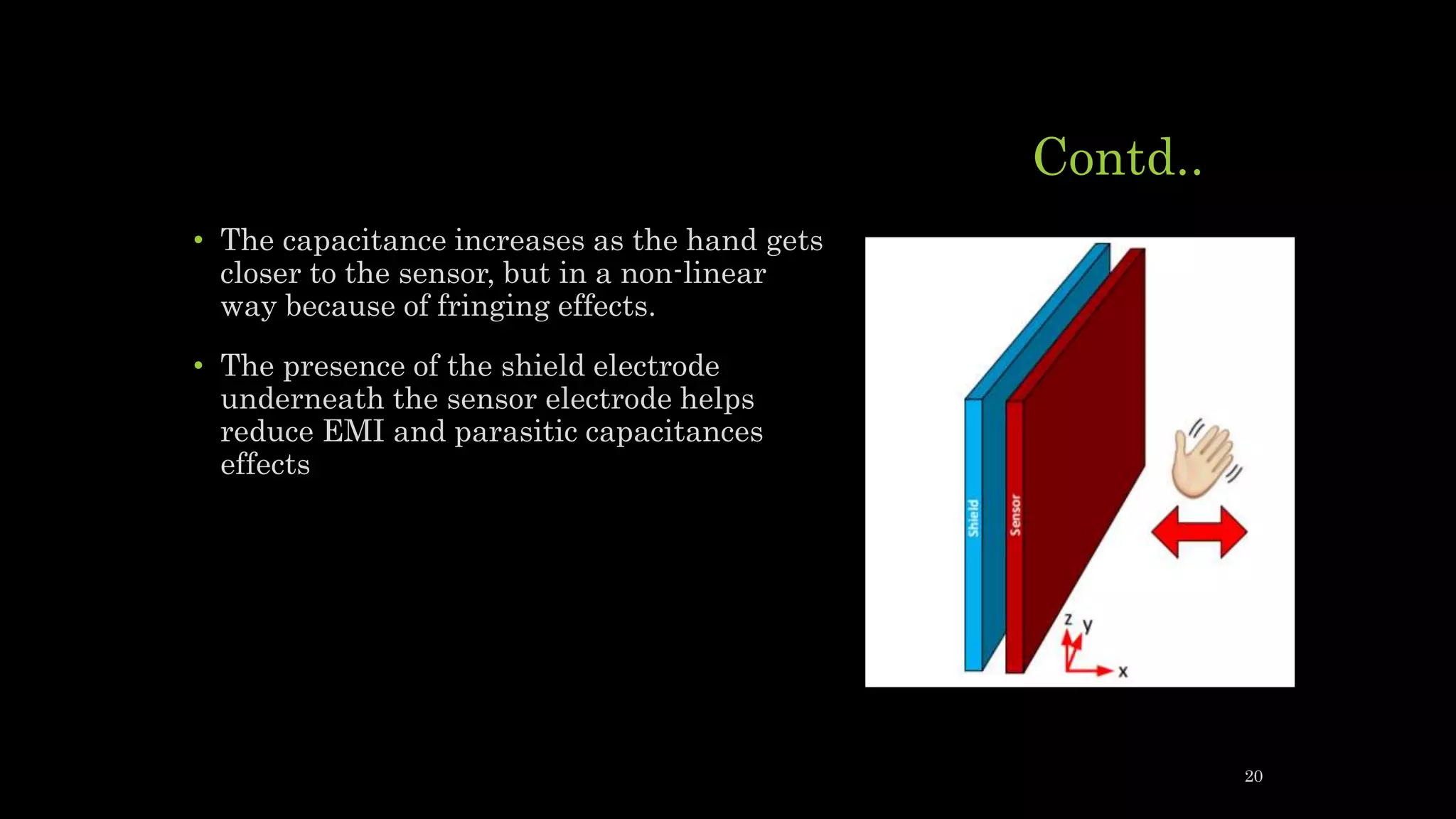

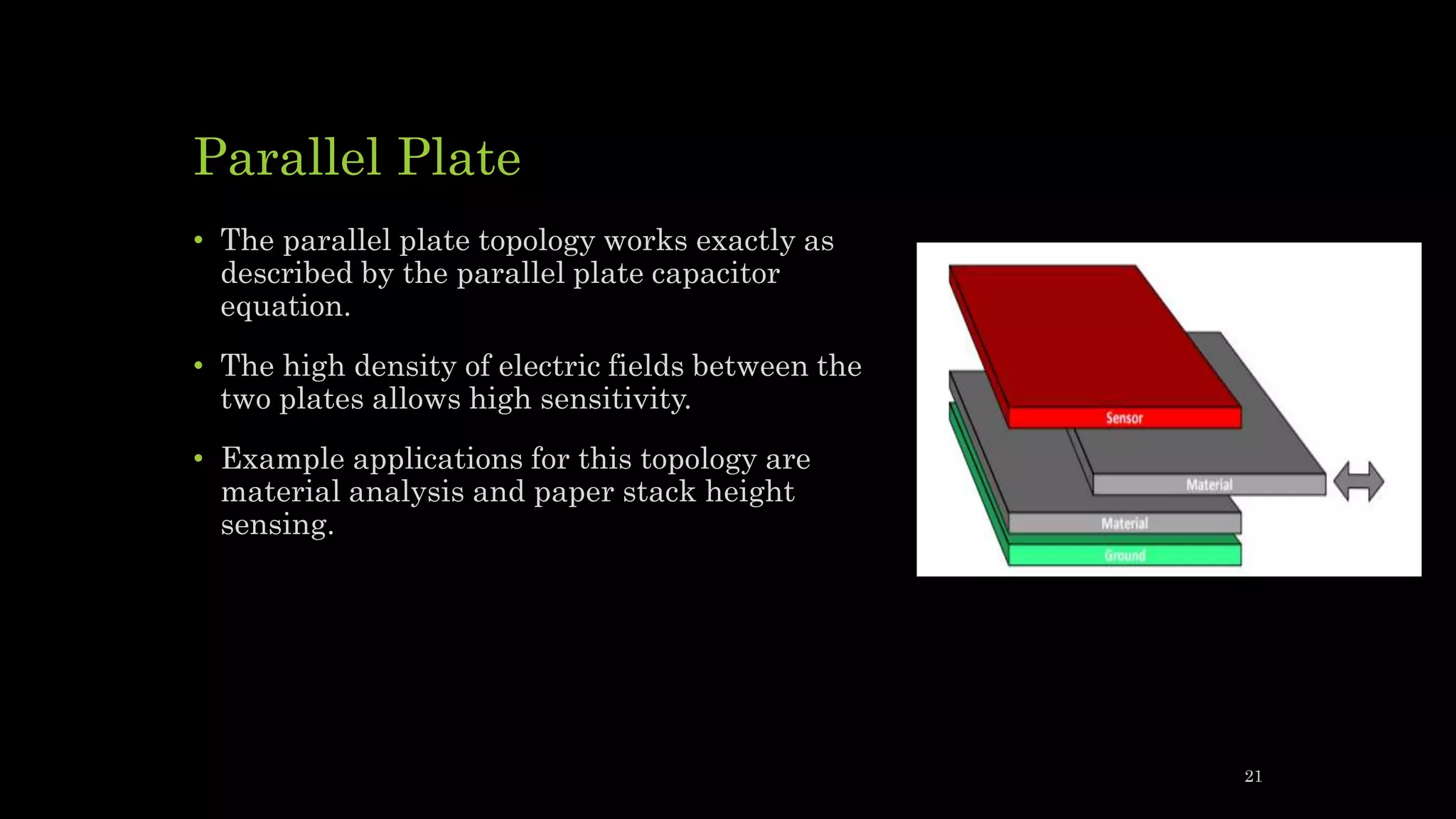

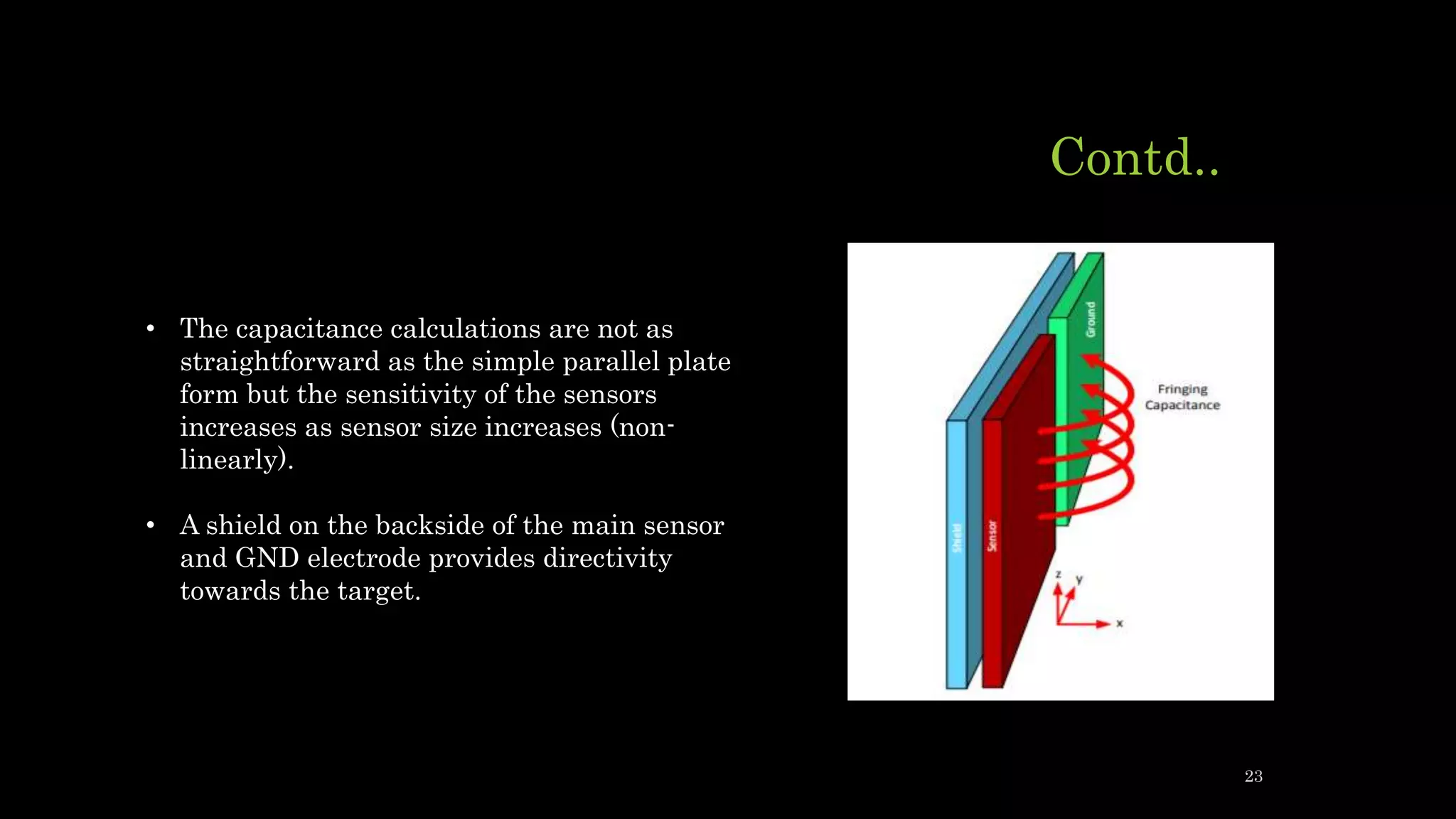

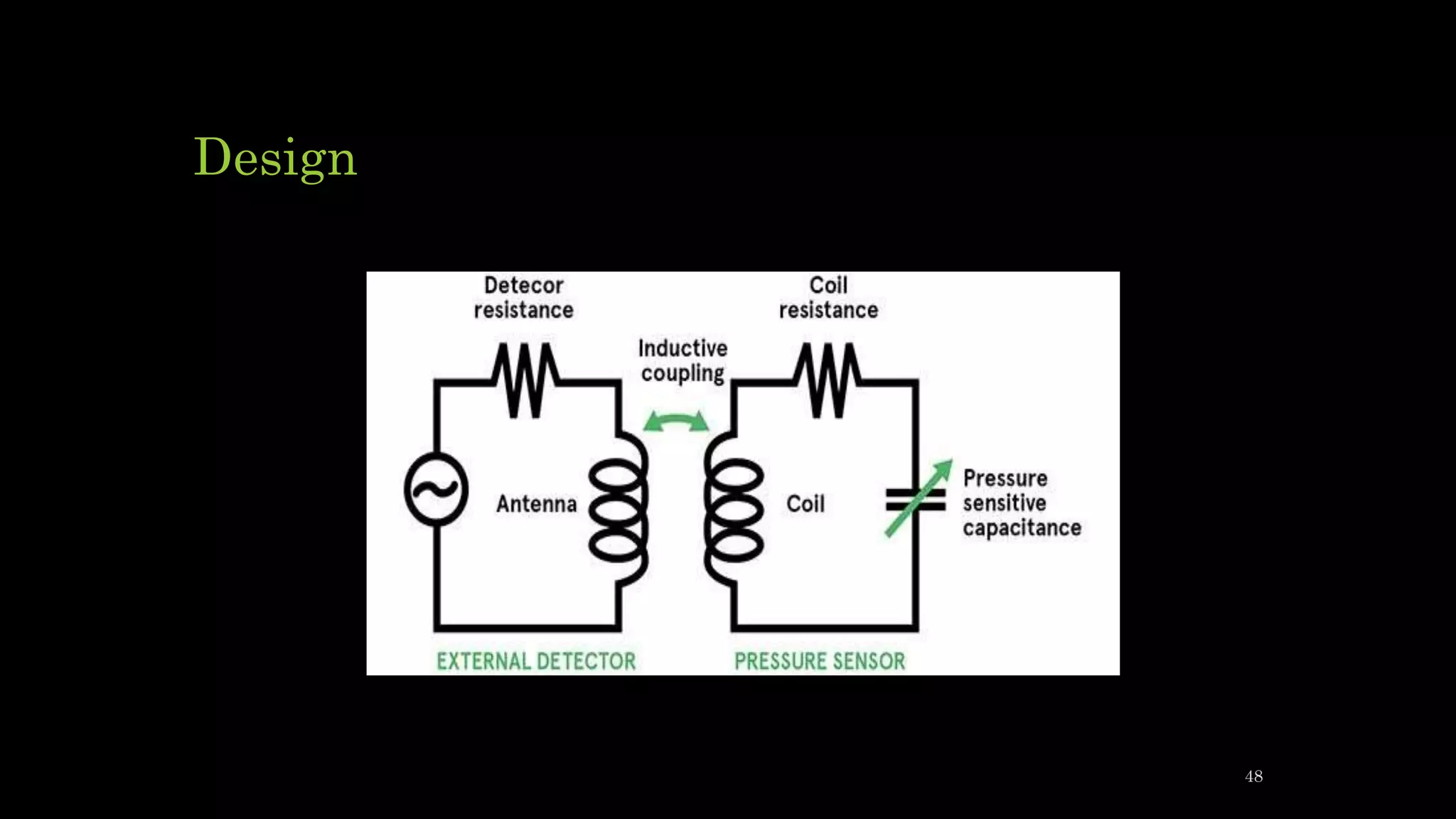

Capacitive sensing technology is an emerging method for detecting various materials, offering advantages such as contactless operation, low cost, and miniaturization. It employs capacitive coupling to sense conductive or dielectric materials and is utilized in touchscreens, buttons, and liquid level sensing applications. Techniques include surface, self, and mutual capacitance, with design considerations impacting sensitivity and performance across different environments.