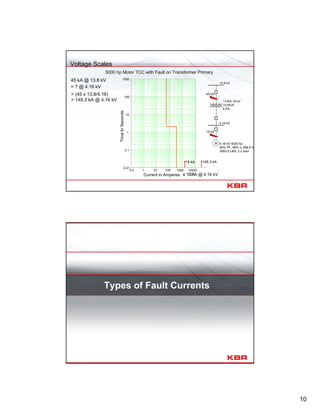

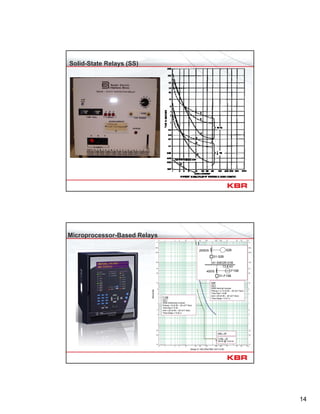

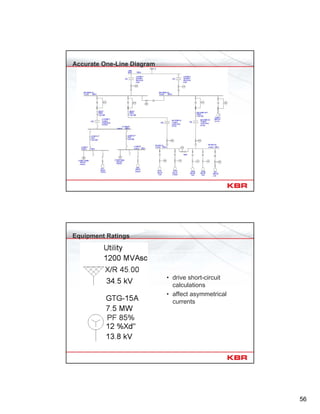

This document provides an agenda and overview for a two-day seminar on overcurrent protection and coordination for industrial applications. Day 1 will cover topics such as the information required for coordination, time-current curves, fault currents, protective devices and coordination time intervals. Day 2 will focus on overcurrent protection for specific equipment such as transformers, motors, conductors and generators. The presenter's biography is provided, noting his engineering experience in power system planning and protection, including serving as an assistant technical editor for an IEEE standard on overcurrent protection.