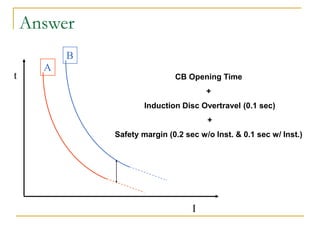

The document discusses power system protection and protective device coordination. It defines overcurrent coordination as the systematic study of current responsive devices in an electrical power system to determine ratings and settings to isolate faults and overloads. The objective is to open only protective devices upstream of the fault or overload. Analysis is needed for new or expanded electrical systems. Protective device coordination requires compromises between protection, speed, reliability and economics.