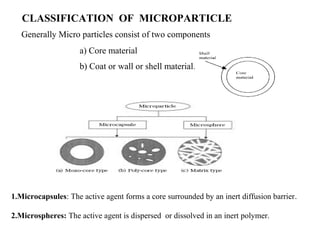

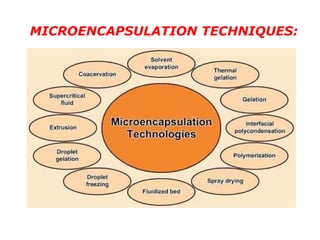

Microencapsulation is a process of coating solid or liquid active ingredients within inert polymeric materials to form microparticles or microcapsules between 3-800μm in diameter. There are various techniques for microencapsulation including air suspension, coacervation, spray drying, solvent evaporation, and polymerization. Microencapsulation can be used to increase bioavailability, alter drug release profiles, improve patient compliance, produce targeted drug delivery, and mask unpleasant tastes. Evaluation of the microcapsules involves determining yield percentage, particle size analysis, encapsulation efficiency, drug content, and drug release studies.

![Percentage Yield

The total amount of microcapsules obtained was weighed and

the percentage yield calculated taking into consideration the

weight of the drug and polymer [7].

Percentage yield = Amount of microcapsule obtained /

Theoretical Amount×100

Scanning electron microscopy

Scanning electron photomicrographs of drug loaded ethyl

cellulose microcapsules were taken. A small amount of

microcapsules was spread on gold stub and was placed in the

scanning electron microscopy (SEM) chamber.

The SEM photomicrographs was taken at the

acceleration voltage of 20 KV.

EVALUATION OF MICROCAPSULES](https://image.slidesharecdn.com/microencapsulation2-121016104845-phpapp01-150325055257-conversion-gate01/85/Microencapsulation-SIDDANNA-M-BALAPGOL-27-320.jpg)

![Particle size analysis

For size distribution analysis, different sizes in a

batch were separated by sieving by using a set of

standard sieves. The amounts retained on

different sieves were weighed [5].

Encapsulation efficiency [8]

Encapsulation efficiency was calculated using

the formula:

Encapsulation efficiency = Actual Drug Content /

Theoretical Drug Content ×100](https://image.slidesharecdn.com/microencapsulation2-121016104845-phpapp01-150325055257-conversion-gate01/85/Microencapsulation-SIDDANNA-M-BALAPGOL-28-320.jpg)

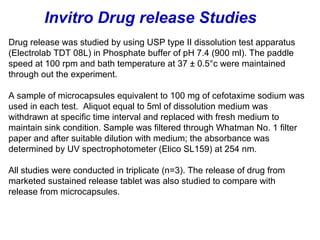

![Cefotaxime sodium drug content in the microcapsules was

calculated by UV spectrophotometric (Elico SL159 Mumbai

India) method.

The method was validated for linearity, accuracy and

precision. A sample of microcapsules equivalent to 100 mg

was dissolved in 25 ml ethanol and the volume was

adjusted upto 100 ml using phosphate buffer of pH 7.4. The

solution was filtered through Whatman filter paper. Then the

filtrate was assayed for drug content by measuring the

absorbance at 254 nm after suitable dilution [9].

Estimation of Drug Content](https://image.slidesharecdn.com/microencapsulation2-121016104845-phpapp01-150325055257-conversion-gate01/85/Microencapsulation-SIDDANNA-M-BALAPGOL-29-320.jpg)