The seminar presented by Sagar B. Thoke focuses on microencapsulation techniques, emphasizing the definition, reasons for encapsulation, manufacturing techniques, and various applications. Microencapsulation involves enclosing core materials with polymeric coatings to protect them and control their release, which has significant implications in pharmaceuticals, agriculture, and food industries. Techniques discussed include air-suspension coating, centrifugal extrusion, spray-drying, and various physico-chemical methods, highlighting the process's complexity and industrial applicability.

![I] Physical or Physico-mechanical methods

16

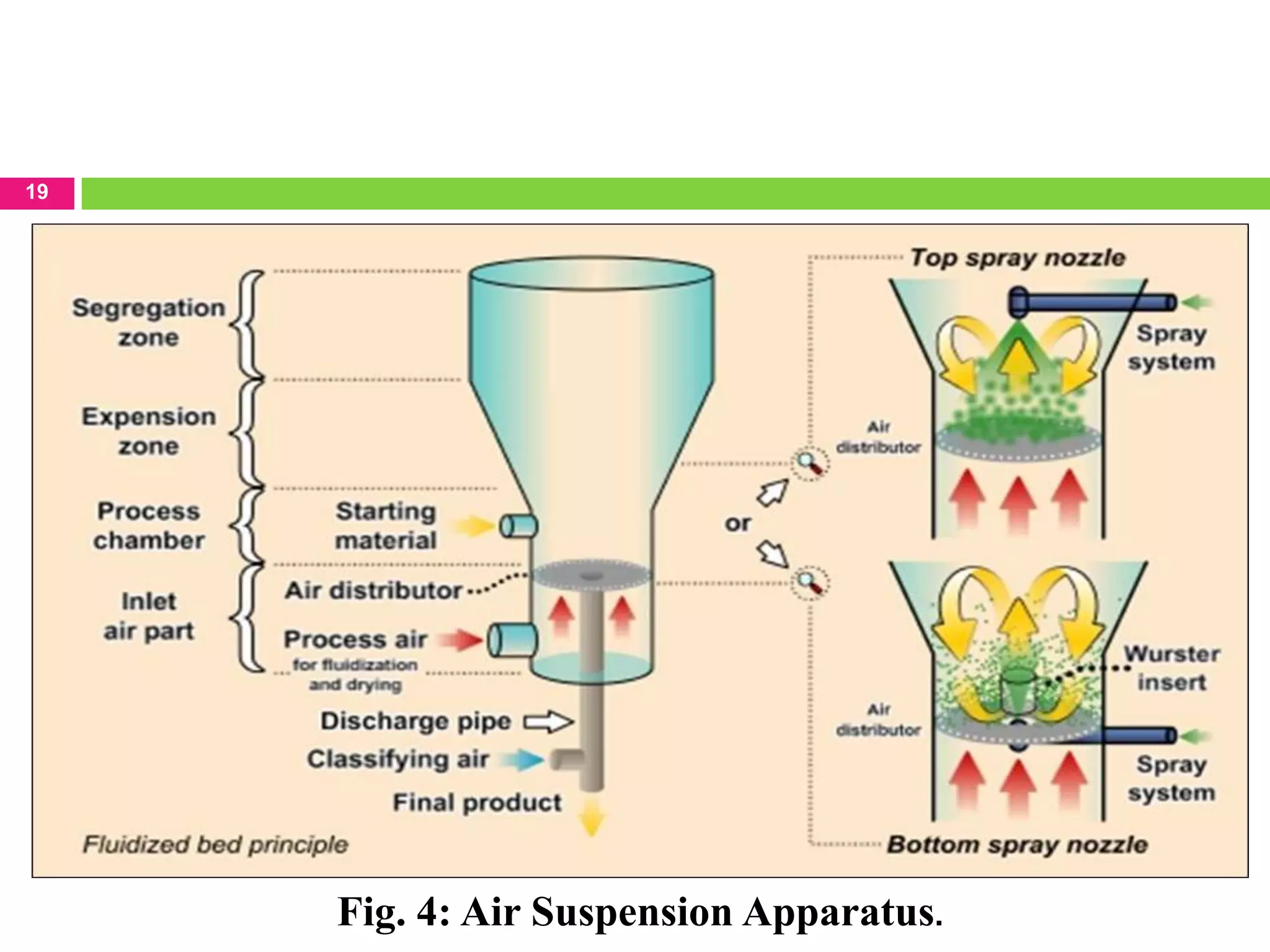

1. Air-suspension coating

Inventions of Professor Dale E. Wurster

Basically the wurster process consists of the dispersing of solid,

particulate core materials in a supporting air stream and the

spray-coating of the air suspended particles.

Equipment ranging in capacities from one pound to 990 pounds.

Micron or submicron particles can be effectively encapsulated

by air suspension techniques.](https://image.slidesharecdn.com/sagarthoke-120411004844-phpapp02/75/MICROENCAPSULATION-TECHNIQUES-AND-APPLICATION-16-2048.jpg)

![II] Physico-chemical methods

29

1. Ionotropic gelation

Chemical reaction between sodium alginate and calcium

chloride or other Counter ion solution such as barium chloride.

Verapamil hydrochloride causes gastric irritation on sudden

release. It is usually administered as conventional tablets

containing 40-120 mg, 3 times a day. Due to its ready solubility

in water and shorter half-life.

Microparticulate system of verapamil hydrochloride for

prolonged release delivery system.](https://image.slidesharecdn.com/sagarthoke-120411004844-phpapp02/75/MICROENCAPSULATION-TECHNIQUES-AND-APPLICATION-29-2048.jpg)

![III] Chemical process

32

1. Solvent Evaporation

In the case in which the core material is dispersed in the

polymer solution, polymer shrinks around the core. In the case

in which core material is dissolved in the coating polymer

solution, a matrix - type microcapsule is formed.

The core materials may be either

water - soluble or

water - insoluble materials.

A variety of film - forming polymers can be used as coatings.](https://image.slidesharecdn.com/sagarthoke-120411004844-phpapp02/75/MICROENCAPSULATION-TECHNIQUES-AND-APPLICATION-32-2048.jpg)

![4] Applications of Microcapsules and Microspheres

36

1. Agricultural Applications

Reduce insect populations by disrupting their mating process.

Protects the pheromone from oxidation and light during storage

and release.](https://image.slidesharecdn.com/sagarthoke-120411004844-phpapp02/75/MICROENCAPSULATION-TECHNIQUES-AND-APPLICATION-36-2048.jpg)

![5] REFERENCES

45

Leon, L., Herbert A. L., Joseph, L. K; “ The Theory And Practice Of Industrial

Pharmacy”, 3rd edition (1990), Varghese Publishing House, Page no.- 412-428.

S.S. Bansode, a review on “Microencapsulation”, International Journal of

Pharmaceutical Sciences Review and Research, Volume 1, Issue 2, March – April 2010;

Article 008; ISSN 0976 – 044X, Page no.- 38-43.

N.K. SACHAN, a review on “Controlled Drug Delivery Through Microencapsula -

tion”, Malaysian Journal of Pharmaceutical Sciences, Volume 4, No. 1, Page no.- 65–81

(2006).

H. Umer, a review on “Microencapsulation: Process, Techniques and Applications”,

International Journal of Research in Pharmaceutical and Biomedical Sciences, Vol. 2 (2)

Apr – Jun 2011, ISSN: 2229-3701, Page no.-447-481.](https://image.slidesharecdn.com/sagarthoke-120411004844-phpapp02/75/MICROENCAPSULATION-TECHNIQUES-AND-APPLICATION-45-2048.jpg)