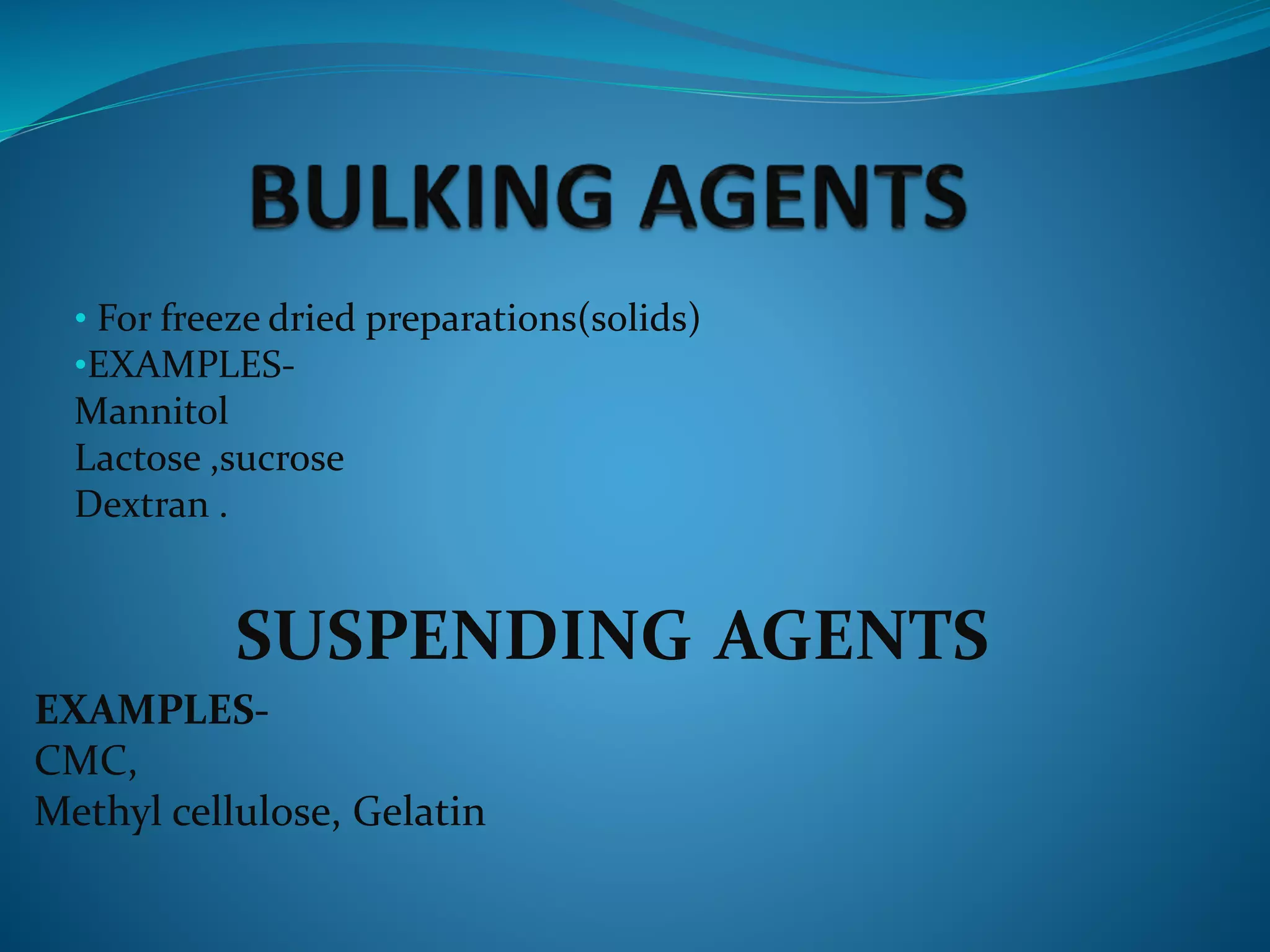

This document discusses parenteral formulations, including definitions, advantages, disadvantages, and classifications. It provides details on the preparation of small volume parenterals and large volume parenterals, including vehicles, buffers, preservatives, and other excipients used. It also covers the stability considerations for parenteral formulations and factors that influence syringeability, injectability, clogging, drainage, resuspendibility, and sedimentation of suspensions.