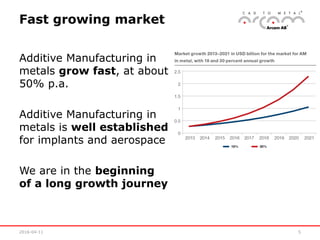

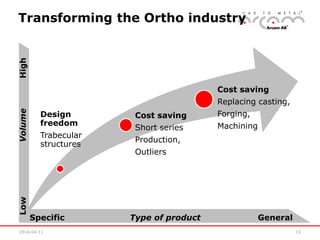

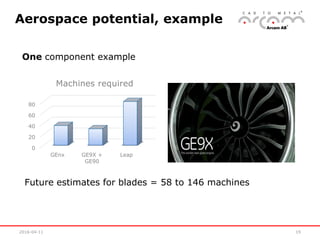

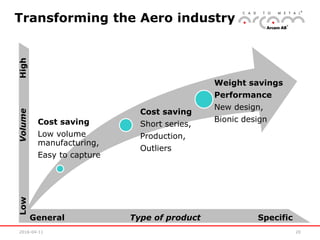

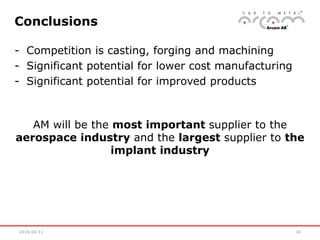

This document discusses the growing use of additive manufacturing (AM) in metal production. It is being used to produce parts for aerospace and medical implant industries. AM allows for design freedom, weight reduction, customized structures, and lower production costs compared to conventional casting and machining. The objective is to transform metal manufacturing industries by transitioning from traditional methods to AM. Major industries like aerospace are embracing AM for cost savings and performance benefits. The future outlook is that AM will become a primary production method for industries like aerospace and medical implants.