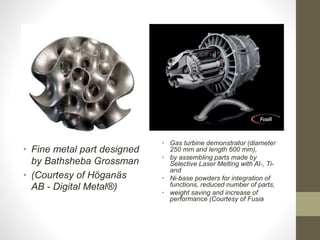

This document discusses additive manufacturing (AM), also known as 3D printing. It begins with definitions of AM and similar terms. Key benefits of AM include increased design freedom, lighter weight structures, and the ability to create complex internal channels or combine multiple parts. The document outlines several industrial sectors utilizing AM like aerospace, energy, and medical. Specific defects that can occur in AM materials if process parameters are incorrect include unmolten powder particles, lacks of fusion, pores, cracks, inclusions, residual stresses, and poor surface roughness.