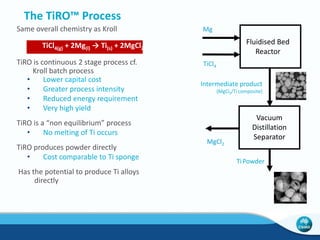

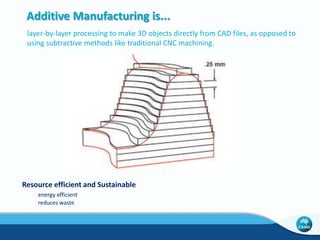

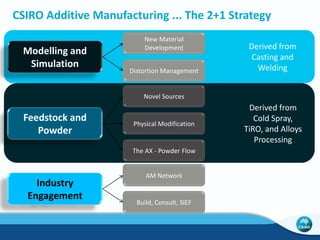

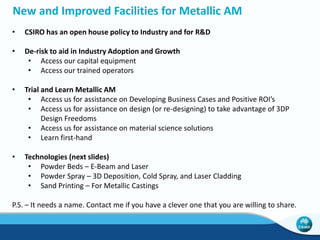

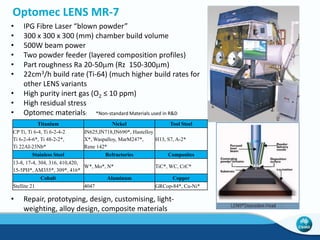

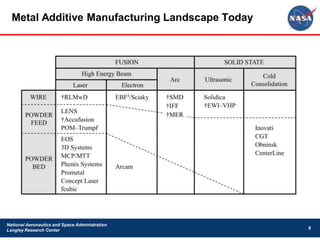

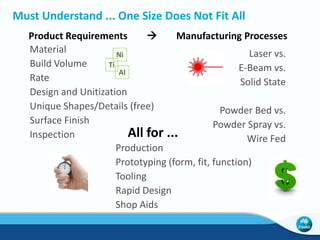

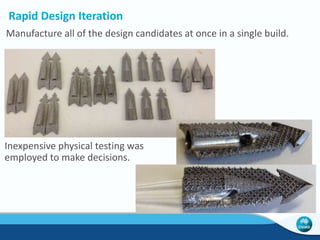

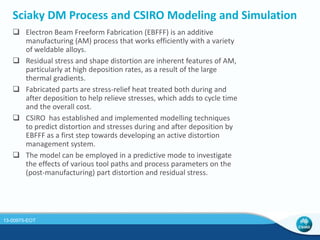

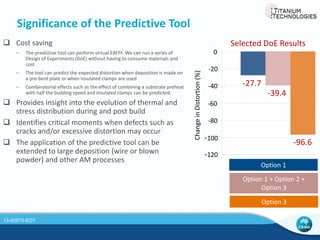

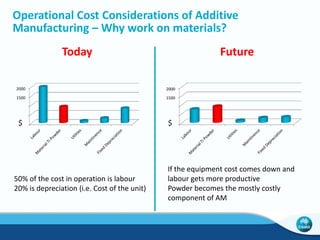

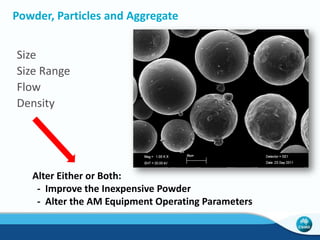

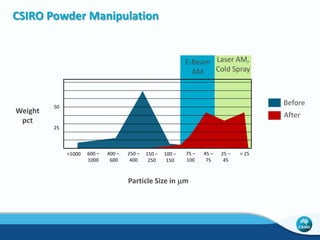

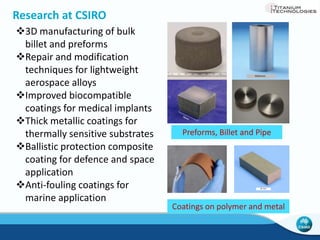

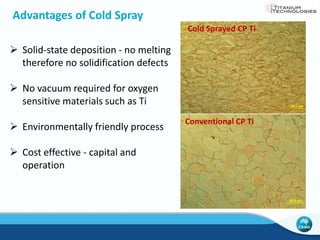

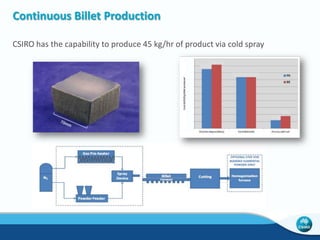

The document provides a comprehensive overview of the high-performance metal industry and metallic additive manufacturing, including strategies, new facilities, and capabilities. It emphasizes resource efficiency, low-cost input materials, thermal modeling for distortion control, and various metal production techniques such as cold spray and 3D printing. Additionally, it outlines industry engagement efforts and the establishment of an additive manufacturing network in Australia to enhance collaboration and innovation within the sector.