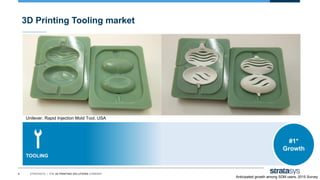

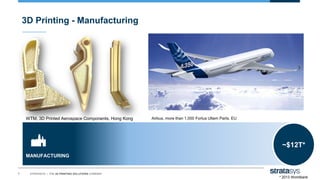

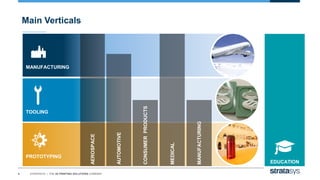

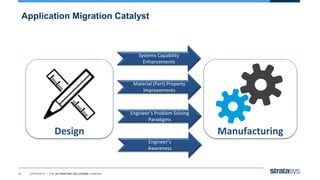

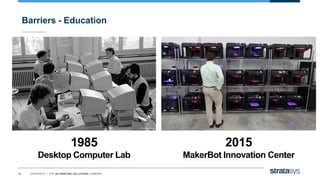

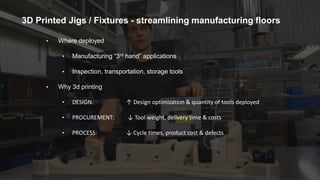

This document discusses 3D printing technologies and their applications beyond prototyping. It begins with an overview of different 3D printing materials including metals, plastics, and photopolymers. It then discusses current and potential applications for 3D printing in tooling, manufacturing, medical, aerospace, and other industries. The document outlines how 3D printing has evolved from primarily prototyping to creating end-use parts and tools, and the factors that have enabled this transition such as improvements in materials and engineers' understanding of design for additive manufacturing.