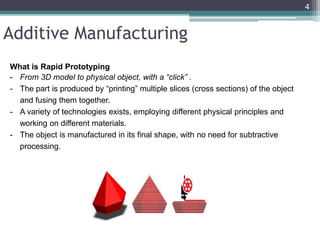

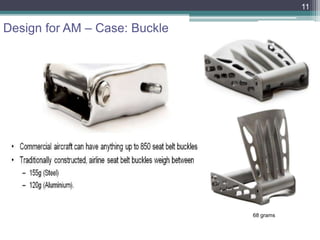

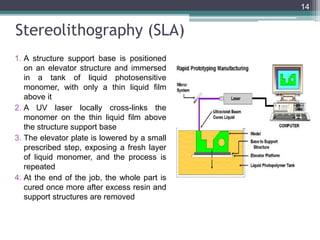

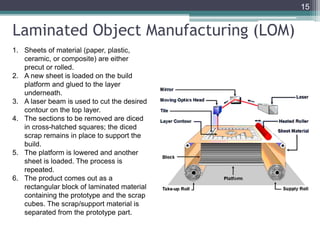

This document provides an overview of additive manufacturing (AM) techniques. It begins by distinguishing between subtractive manufacturing techniques, which remove material from an object, and additive manufacturing, which builds up an object layer by layer. The document then describes several common AM processes including stereolithography (SLA), fused deposition modeling (FDM), selective laser sintering (SLS), and multi-jet modeling (MJM). It explains the basic steps for each technique and highlights applications of AM such as medical implants, hearing aids, food printing, and more. The document aims to outline the key AM techniques and demonstrate the range of potential applications enabled by additive manufacturing.