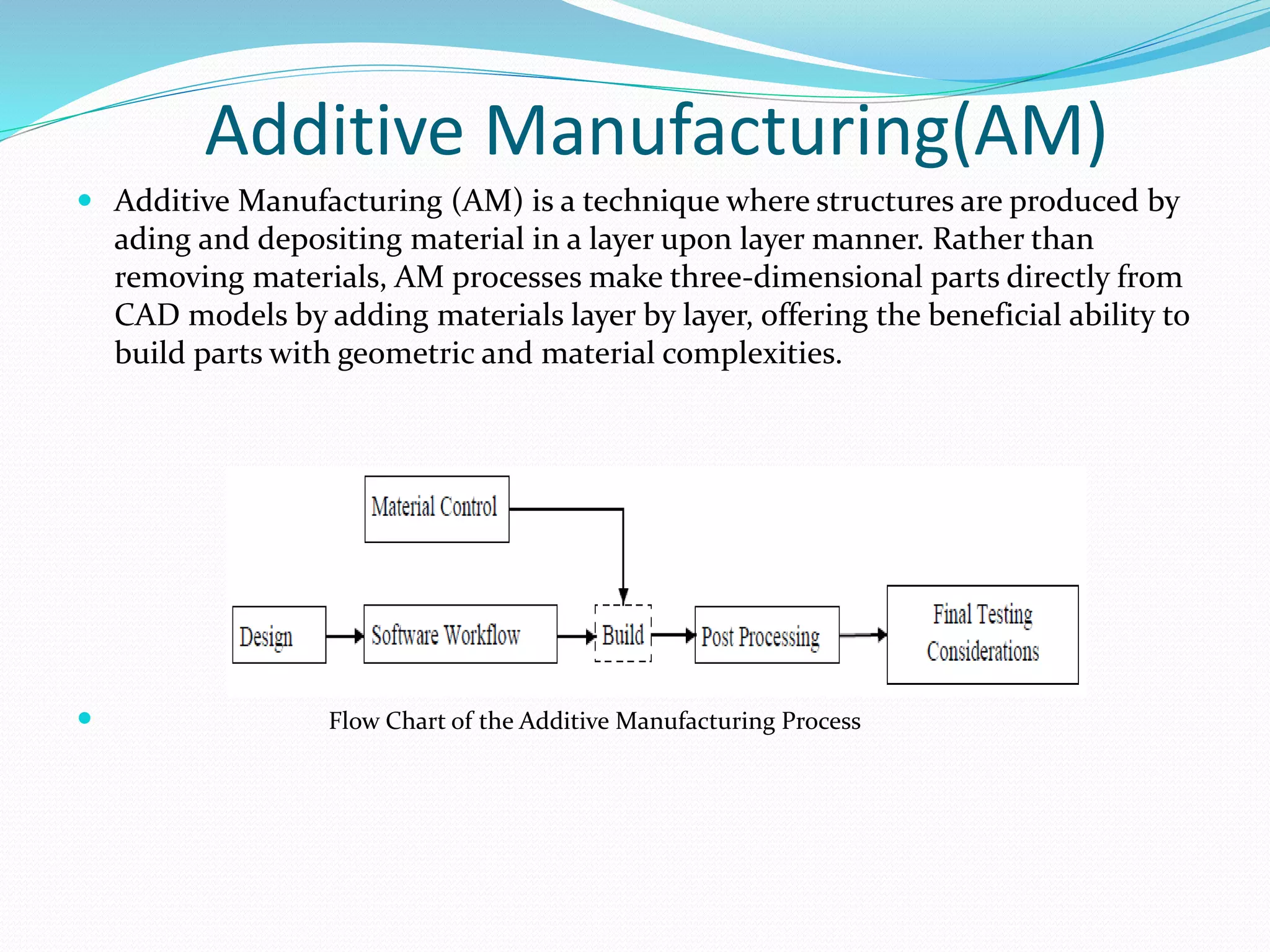

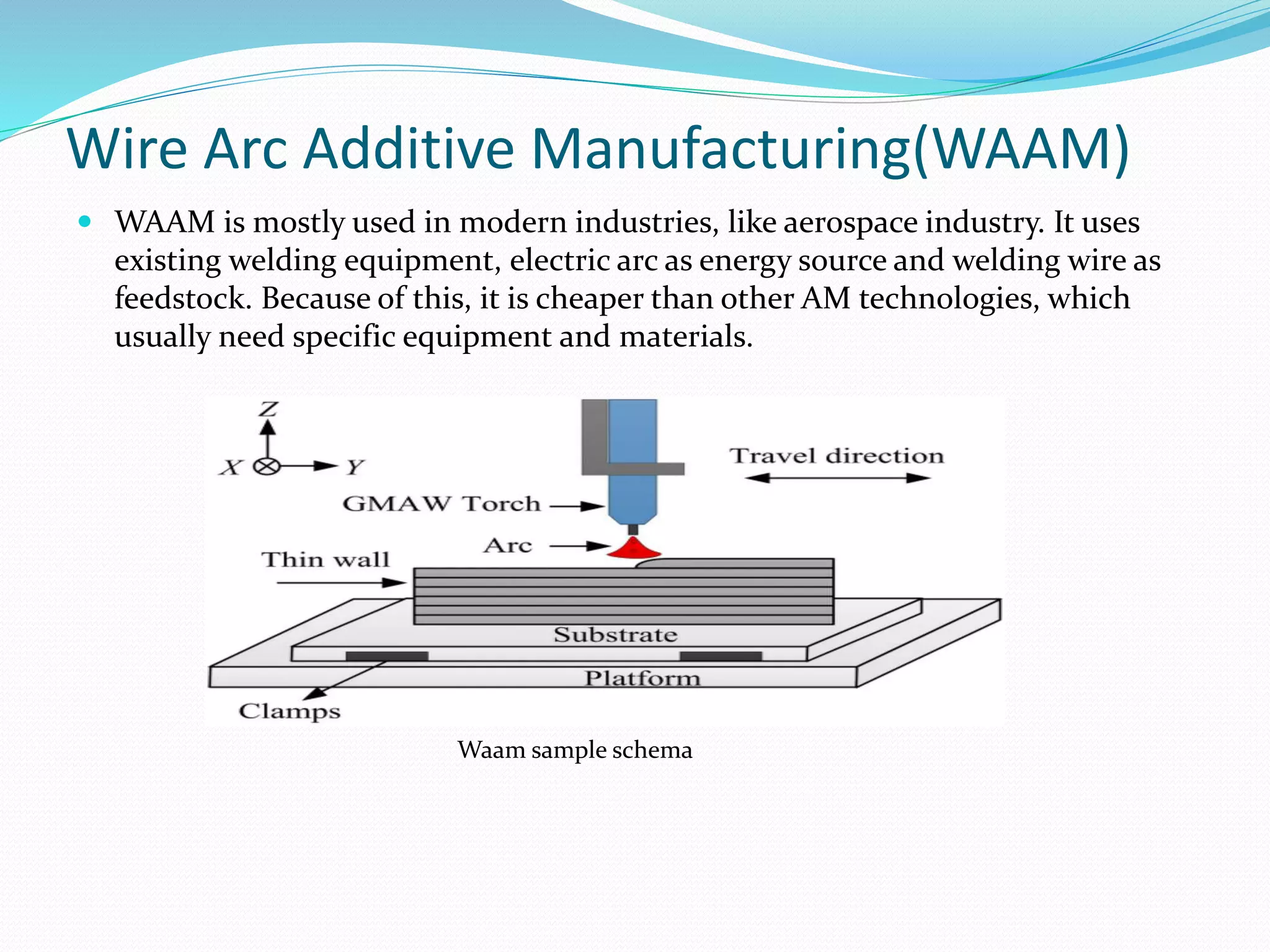

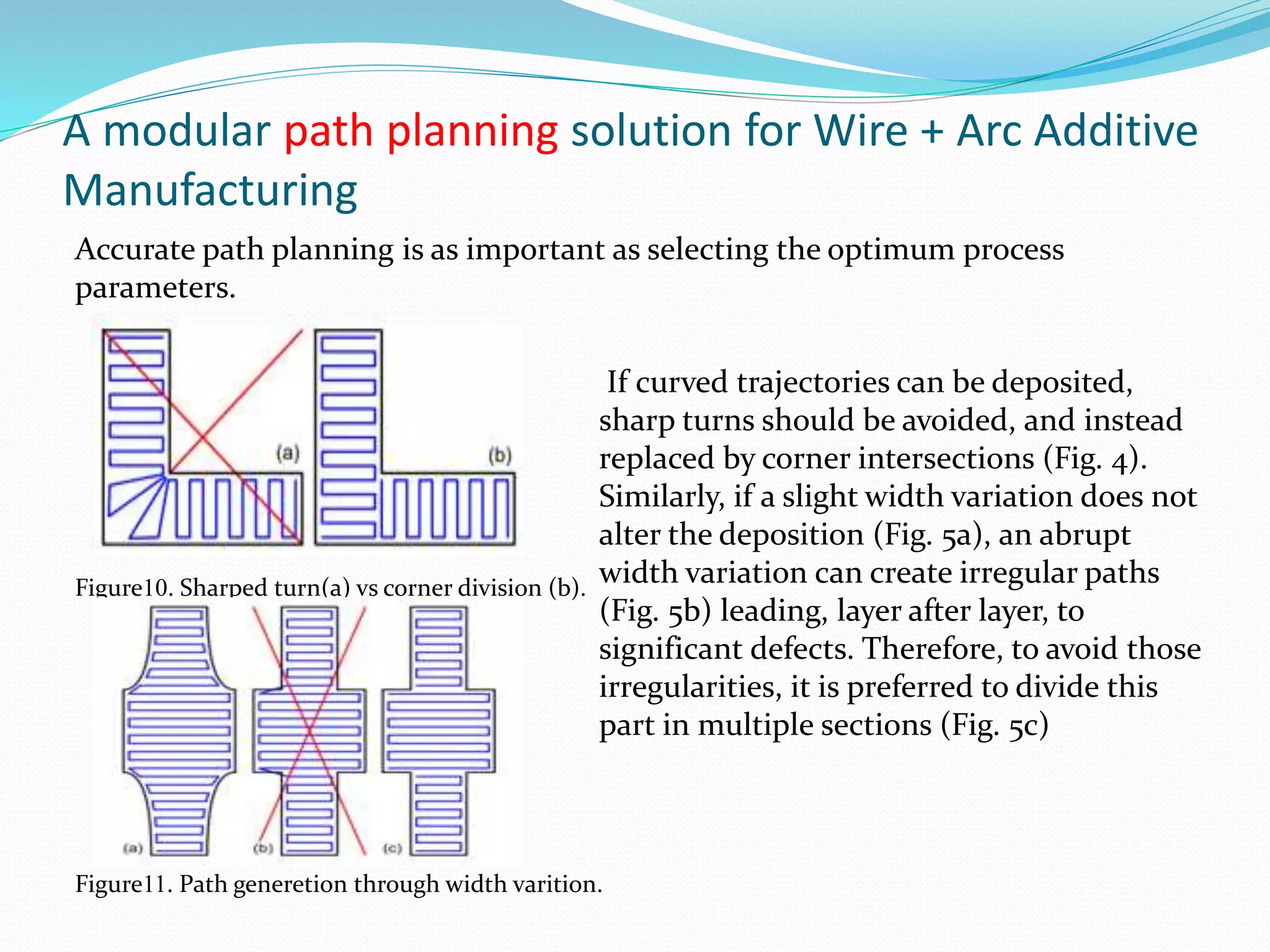

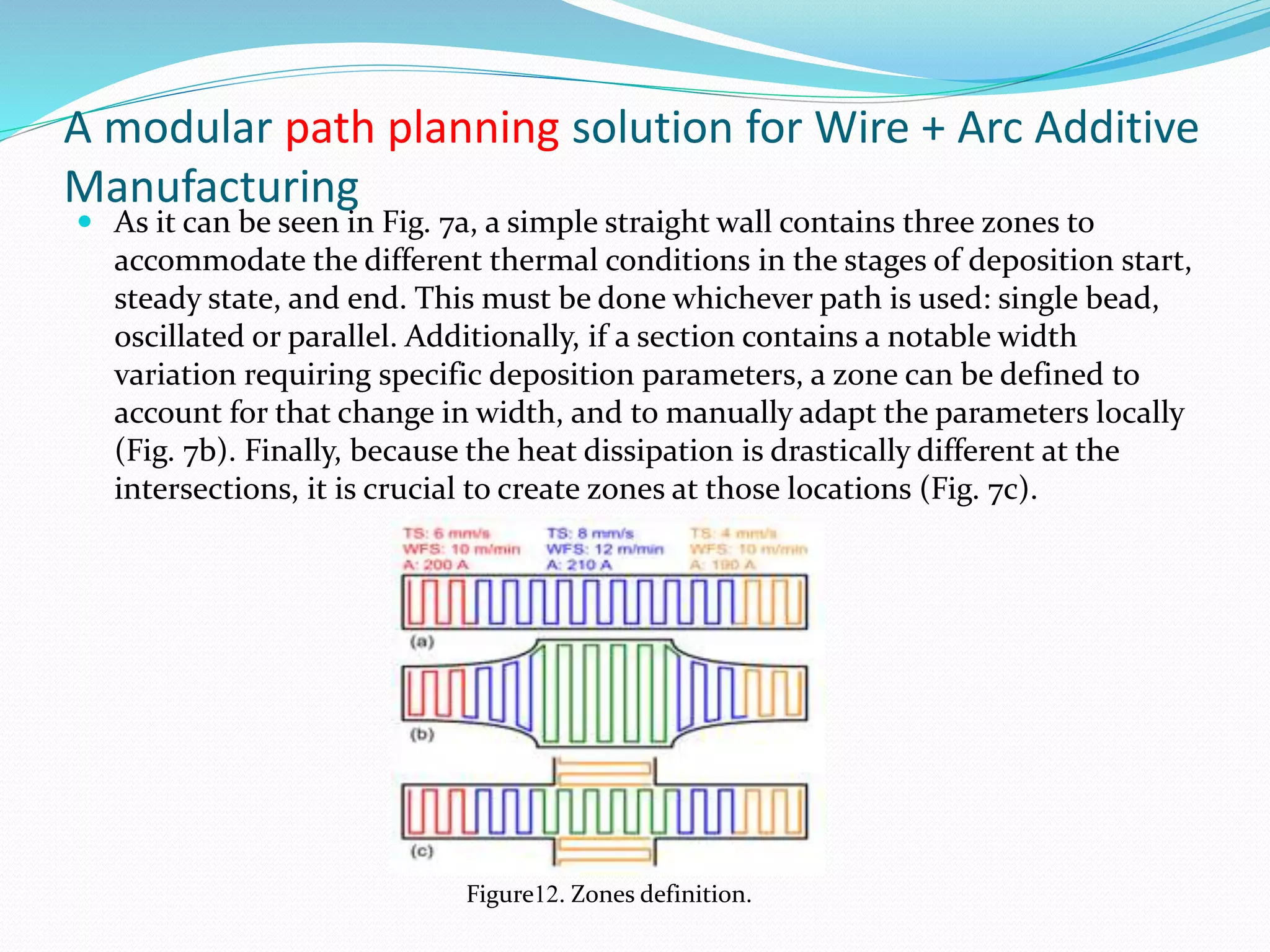

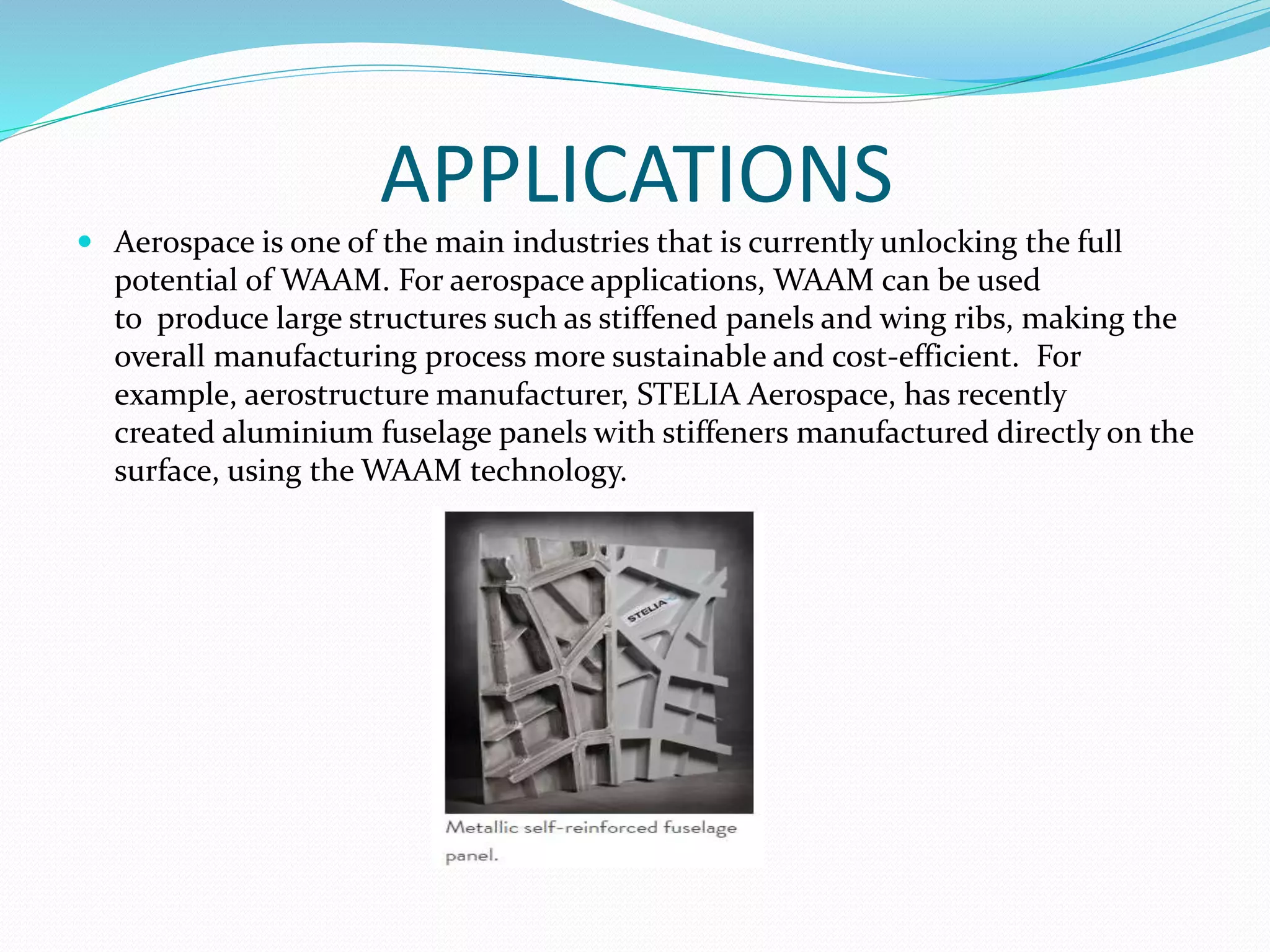

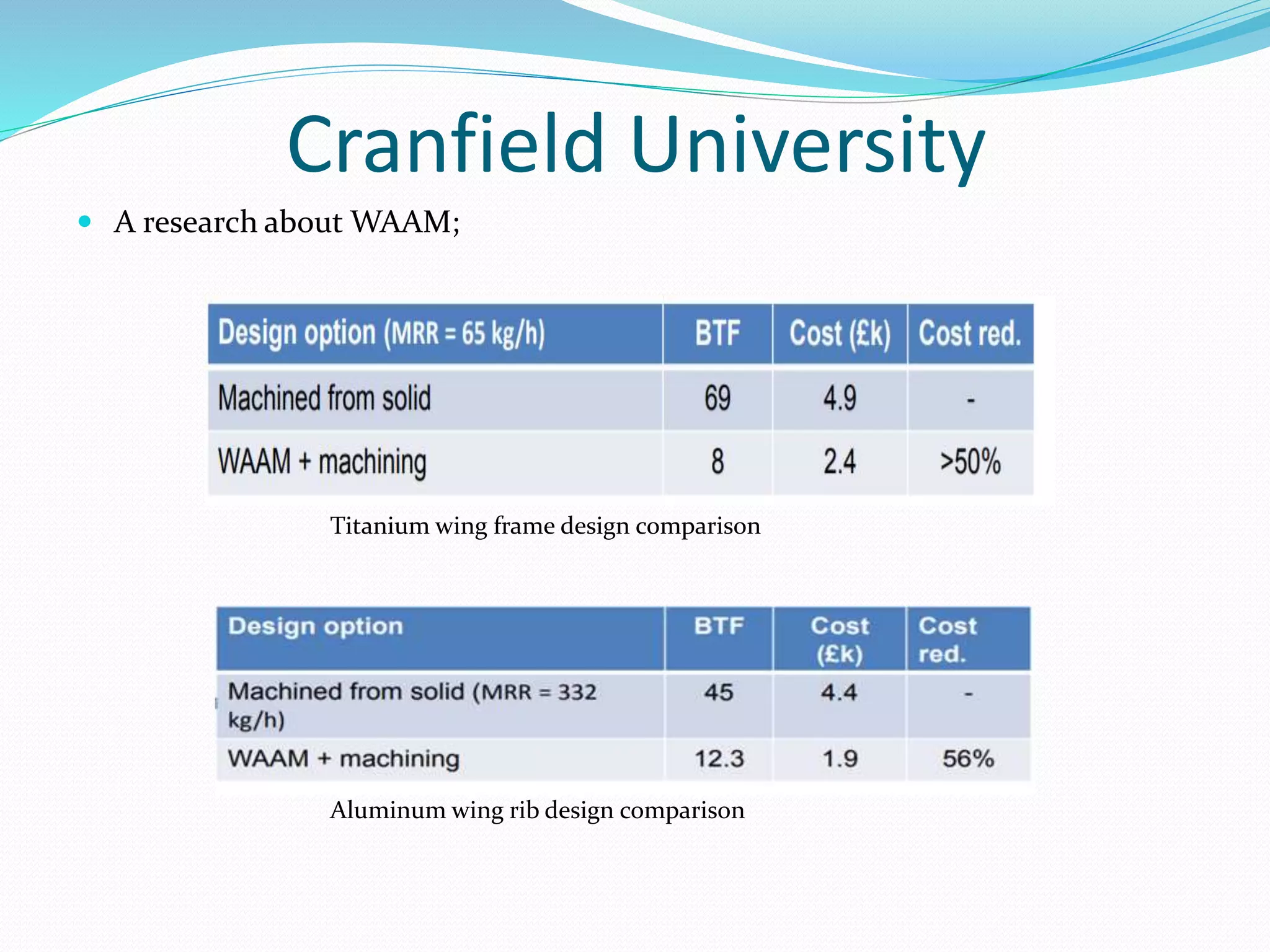

This document discusses wire arc additive manufacturing (WAAM) as an additive manufacturing technique. It begins with an overview of additive manufacturing and describes WAAM as using existing welding equipment with an electric arc energy source and welding wire feedstock. WAAM allows for higher deposition rates compared to laser-based methods and is more cost effective. Applications discussed include aluminum and steel components for the aerospace, automotive, and other industries. Research from Cranfield University is also summarized, describing large metallic parts they have produced with WAAM. Compared to powder-based processes, WAAM has lower geometrical accuracy but better mechanical properties and less porosity.