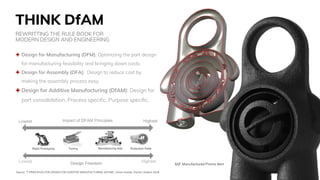

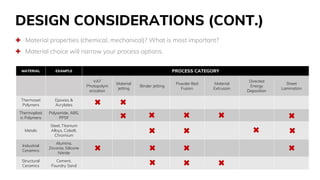

Empire Group is a comprehensive product development company focused on additive manufacturing (AM) and its transformative impact on industries. The document outlines the evolution of 3D printing, the importance of Design for Additive Manufacturing (DFAM), and its implications for innovation in product design and engineering. It emphasizes the necessity for designers and engineers to adapt to these advancements while providing an overview of the company's capabilities and facilities.